Micro LED chip, manufacturing method thereof, and Micro LED array substrate

A manufacturing method and chip technology, applied in the field of optoelectronics, can solve the problems of decreased luminous efficiency, loss of the light-emitting area of MicroLED chips, etc., and achieve the effects of saving occupied area, improving reliability and manufacturing cost, and avoiding shading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

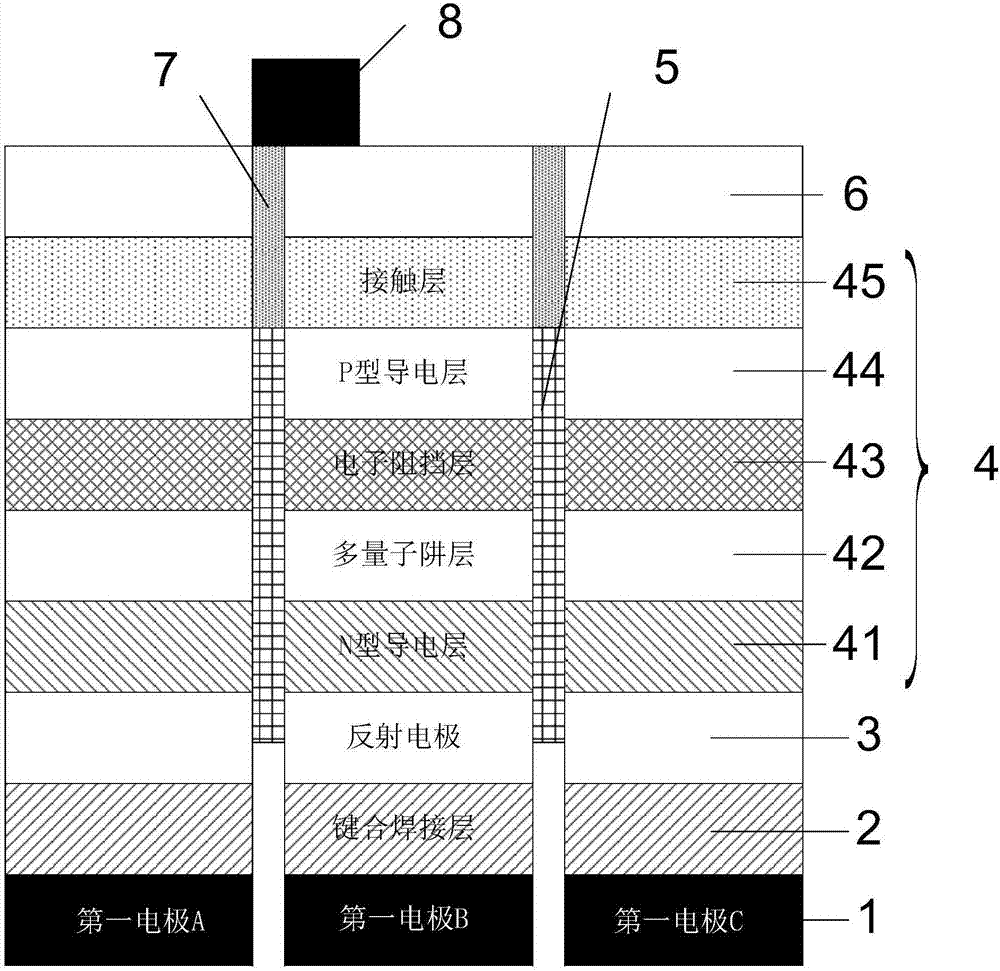

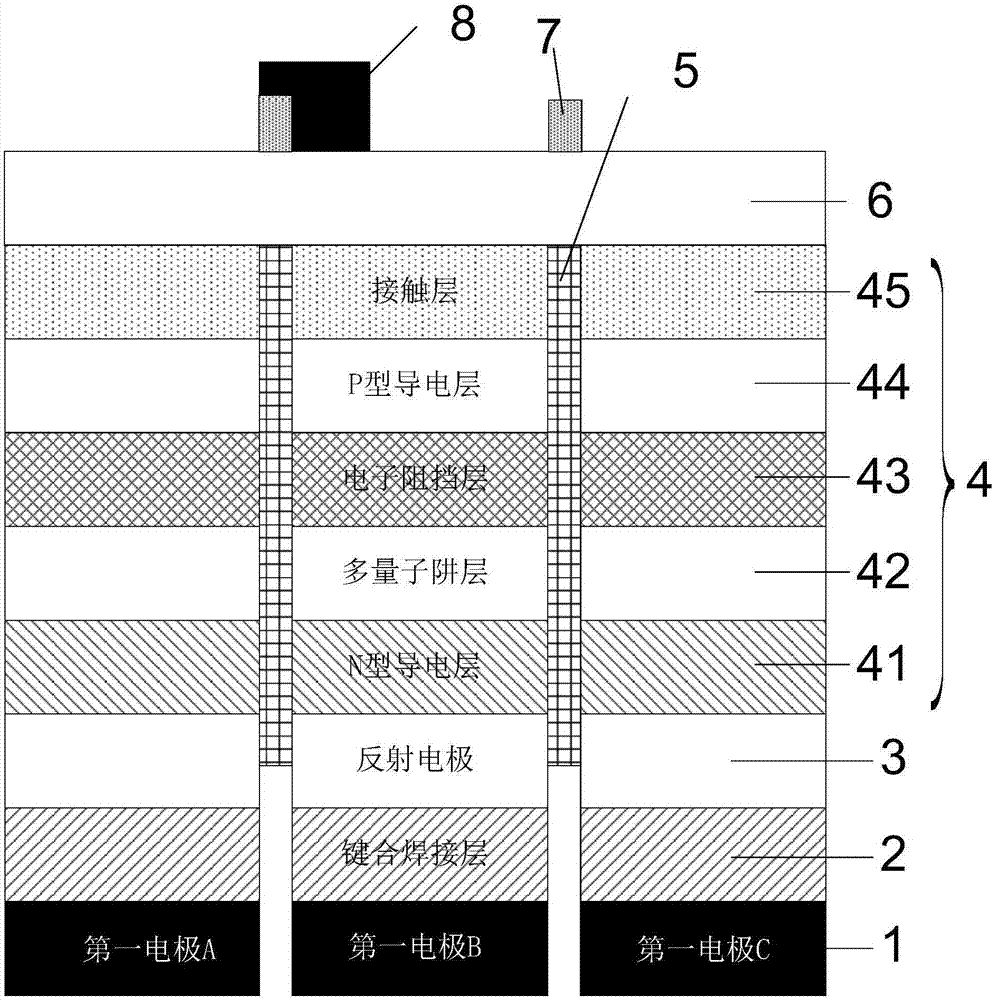

[0063] As mentioned in the background technology section, the Micro LED in the prior art suffers from serious loss of light-emitting area, and the luminous efficiency drops significantly.

[0064] The inventors found that the reason for the above phenomenon is that the same-side electrodes are used in the production process of the Micro LED chip, and the same-side electrodes need to be made in the LED chip of each unit, and the same-side electrodes need to be etched through the active area, while the area of Micro LED chips is small and the number of chips is large, the real sun will occupy a large chip area, resulting in a serious loss of the entire Micro LED light-emitting area, which in turn leads to a significant drop in luminous efficiency.

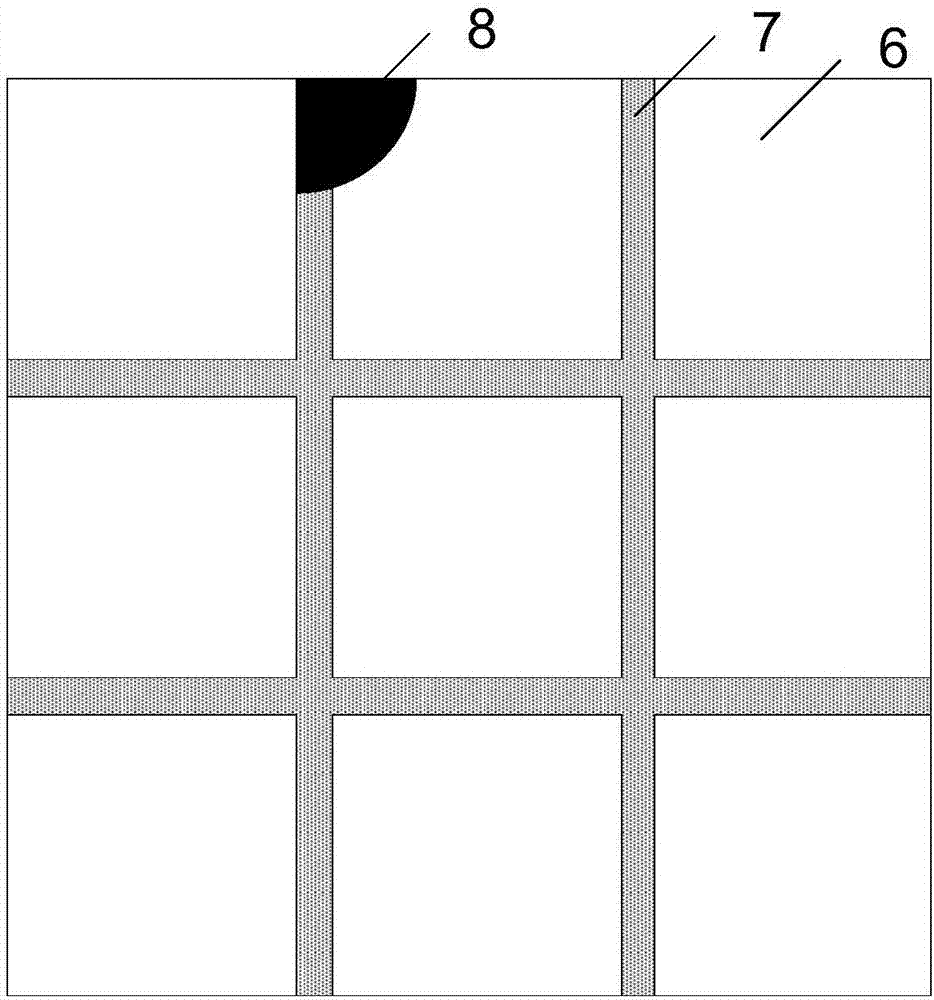

[0065] Based on this, the present invention provides a Micro LED chip, including:

[0066] a plurality of first electrodes arranged in an array and insulated from each other;

[0067] reflective electrodes electrically connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com