Biaxial shear test method of fabric membrane material

A test method and fabric membrane technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, and analyzing materials, can solve the problem of failing to accurately reveal the shear mechanical properties of fabric membrane materials and not meeting the requirements of fabric membrane materials. Technical requirements for fine model shear tests, imperfect biaxial shear test methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention provides a method for biaxial shear testing of fabric membrane materials, comprising the following steps:

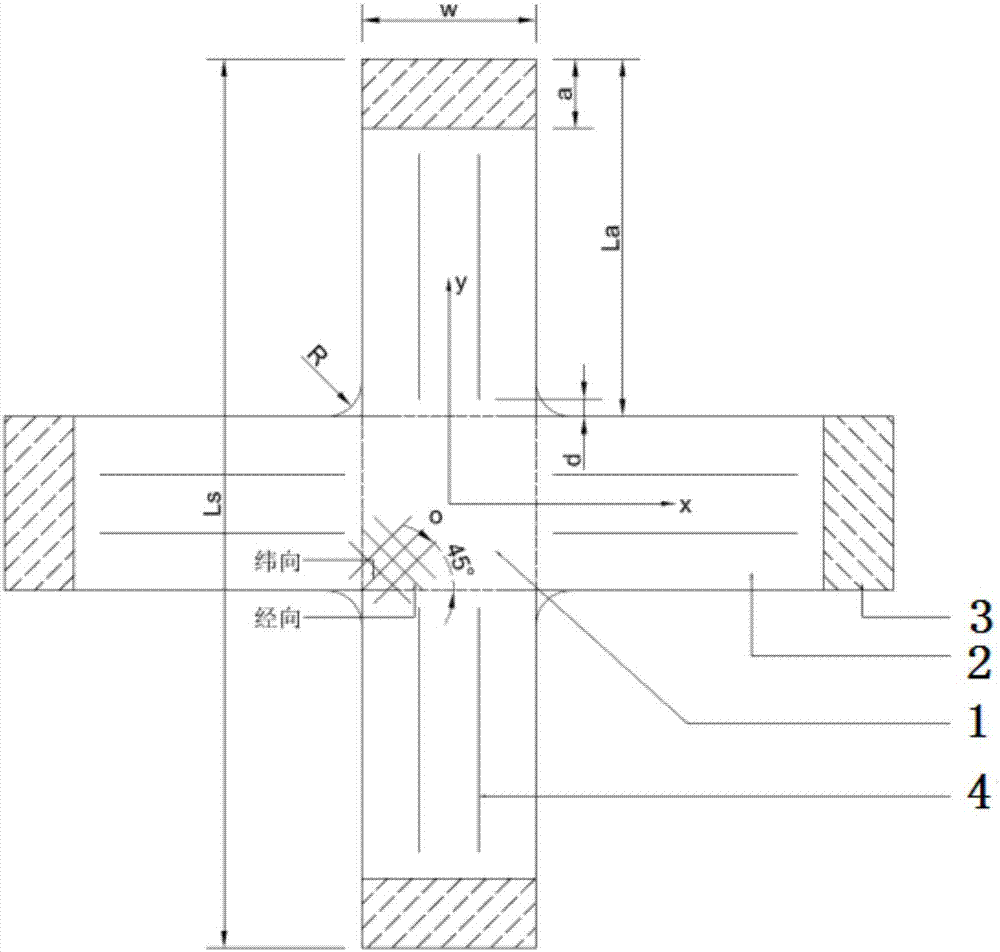

[0036] Step 1. Fabricate a cross-shaped biaxial shear specimen using the fabric membrane material, so that the included angle between the warp and weft direction of the fabric membrane material and the cross-shaped main axis of the specimen is 45°.

[0037] figure 1 shows the top view of the fabricated cross-shaped biaxial shear specimen, which includes a central core area 1 and four outriggers 2, and the ends of the outriggers 2 are clamping segments 3, which are used to connect The fixture of the biaxial tensile testing machine, the outrigger 2 transmits the load applied by the biaxial tensile testing machine to the central core area 1; the central core area 1 is the test area, and the fabric film is obtained by testing the shear deformation of the central core area 1 shear properties of the material. In this embodiment, two high-precision extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com