Cartridge dismounting device

A bullet and elastic technology, applied in the field of bullet dismantling devices, can solve problems such as accidents, bullet scratches, bullet primer deflagration, etc., and achieve the effect of wide application range, convenient operation, simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The patent of the present invention will be described in detail below in conjunction with the drawings, and the following examples can enable those skilled in the art to better understand the patent of the present invention, but will not limit the patent of the present invention in any form.

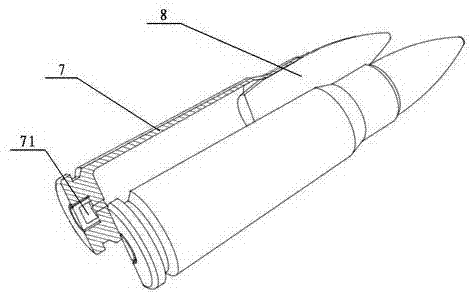

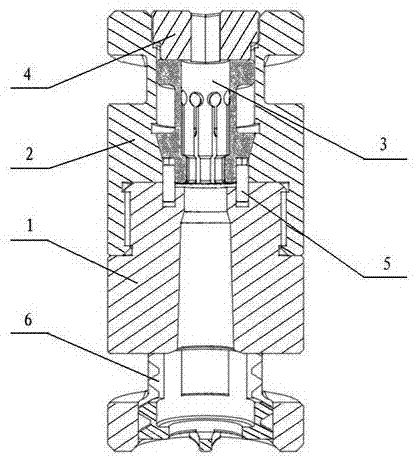

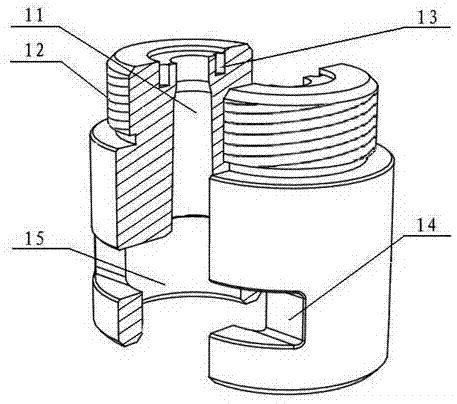

[0028] Such as Figure 2-9 As shown, a bullet dismantling device is composed of a lower base 1, an upper base 2, an elastic hoop 3, a set nut 4, a stop pin 5 and a rubber plug 6, and the upper end of the lower base 1 It is threadedly connected with the lower end of the upper base 2 through the lower disassembly thread 12 of the lower base 1 and the upper disassembly thread 22 of the upper base 2, and the center of the lower base 1 has a shell profiling tapered surface 11 for holding bullet shells , the upper end is processed with the lower pin hole 13 of the anti-rotation pin, and the lower end is processed with a plug matching hole 15 for inserting the rubber plug 6; the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com