Annulus-pressurizing well cementing device

A cementing and annulus technology, applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of cement slurry leakage pressure, cement slurry weight loss, poor isolation quality, etc., to improve solid The effects of well pressure, pressure stability after cementing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

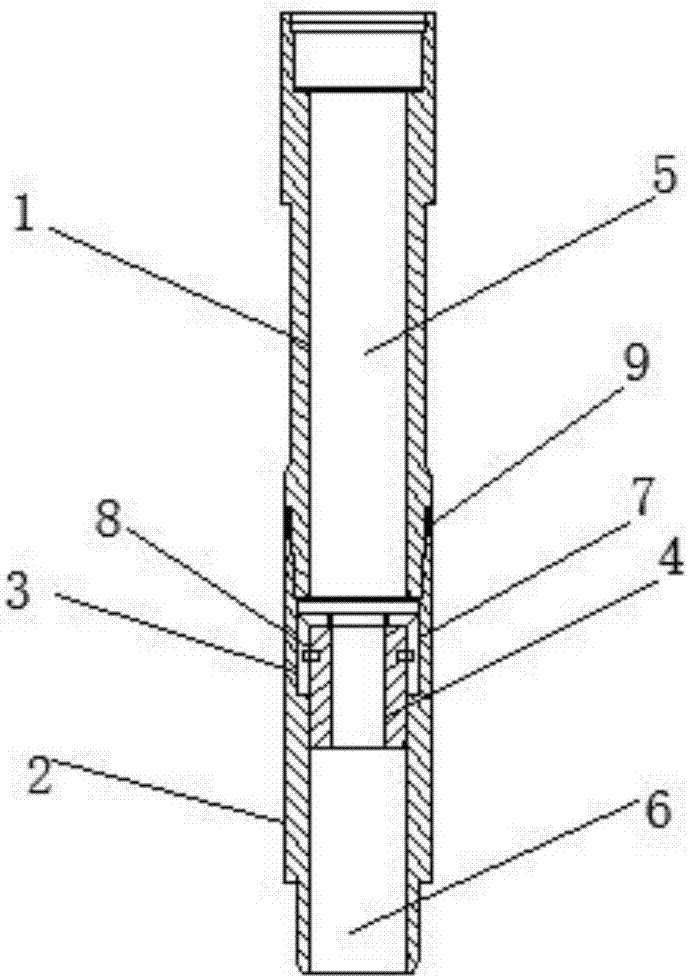

[0029] Such as figure 1 An annulus pressurized well cementing device shown includes an upper joint 1, a lower joint 2, a fixed sleeve 3 and a sliding sleeve 4, the upper joint 1 is installed above the lower joint 2, and the upper joint 1 is provided with a second A cavity 5, a second cavity 6 is arranged inside the lower joint 2, the first cavity 5 corresponds to the second cavity 6, and a fixing sleeve 3 is arranged inside the second cavity 6, so A sliding sleeve 4 is arranged inside the fixed sleeve 3 .

[0030] Wherein, the inner wall of the upper end of the second cavity 6 is provided with a groove 7, and the fixing sleeve 3 is arranged inside the groove 7;

[0031] When in use, the fixed sleeve 3 is placed through the groove 7 provided, so that the sliding sleeve 4 can closely fit with the inside of the second cavity 6 to ensure the reliability of the sliding sleeve and facilitate subsequent pressurization.

[0032] Wherein, it also includes a shear pin 8 arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com