Plate-column structure node of profile steel column and column cap prefabricated component and construction method thereof

A technology of slab-column structure and prefabricated components, which is applied in the direction of building construction and construction, can solve problems that are not assembly structures, problems that need to be solved without consideration of assembly, blank assembly nodes, etc., to reduce installation work, simplify construction procedures, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

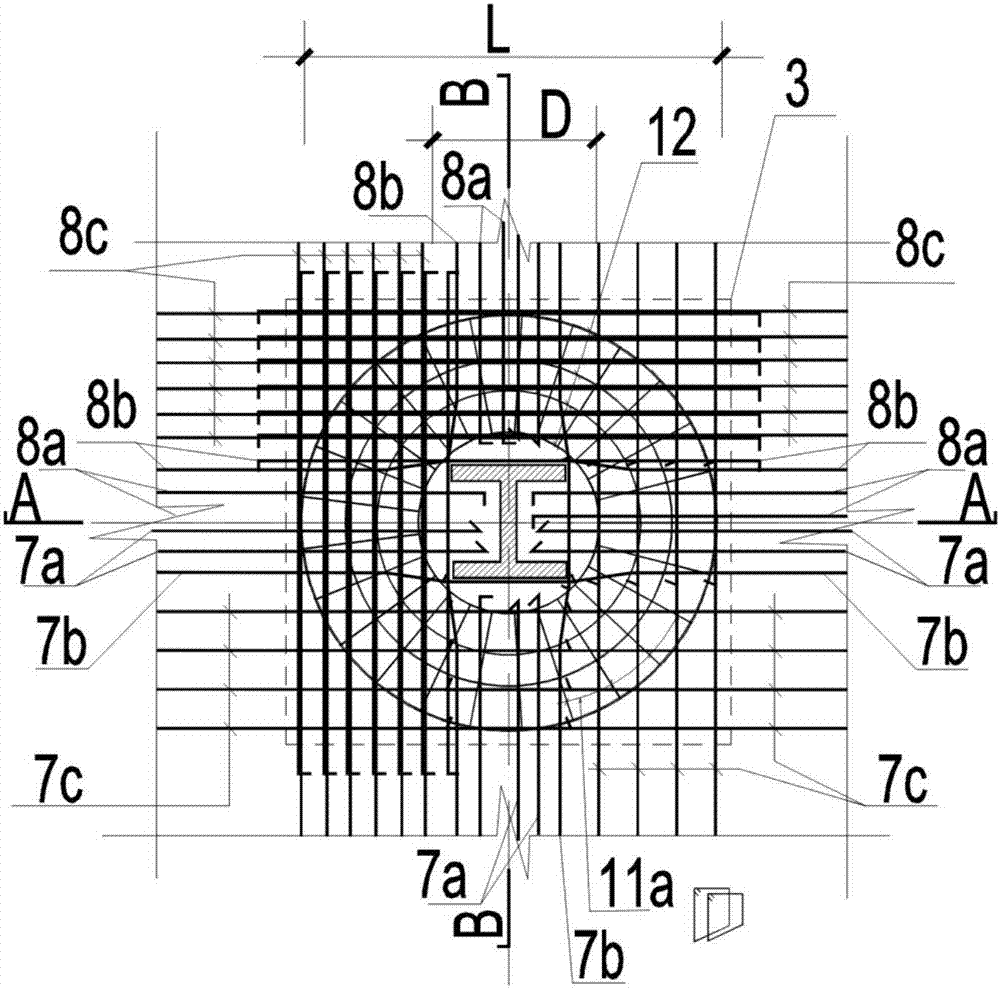

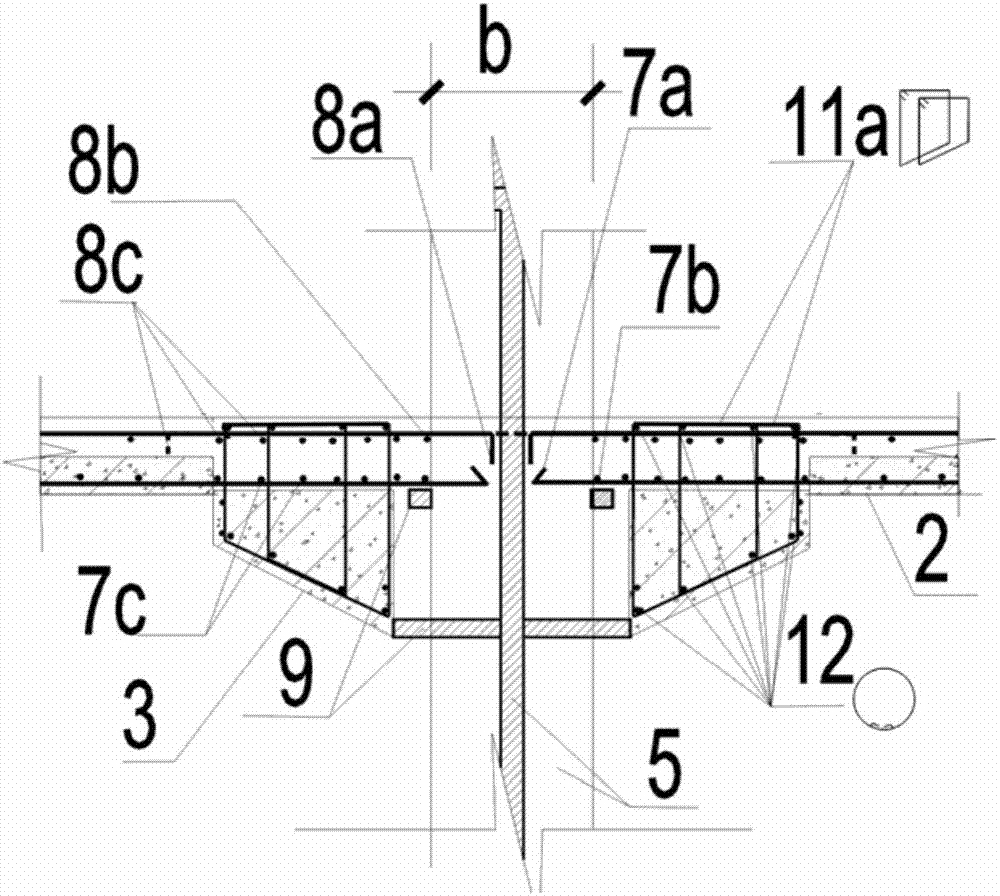

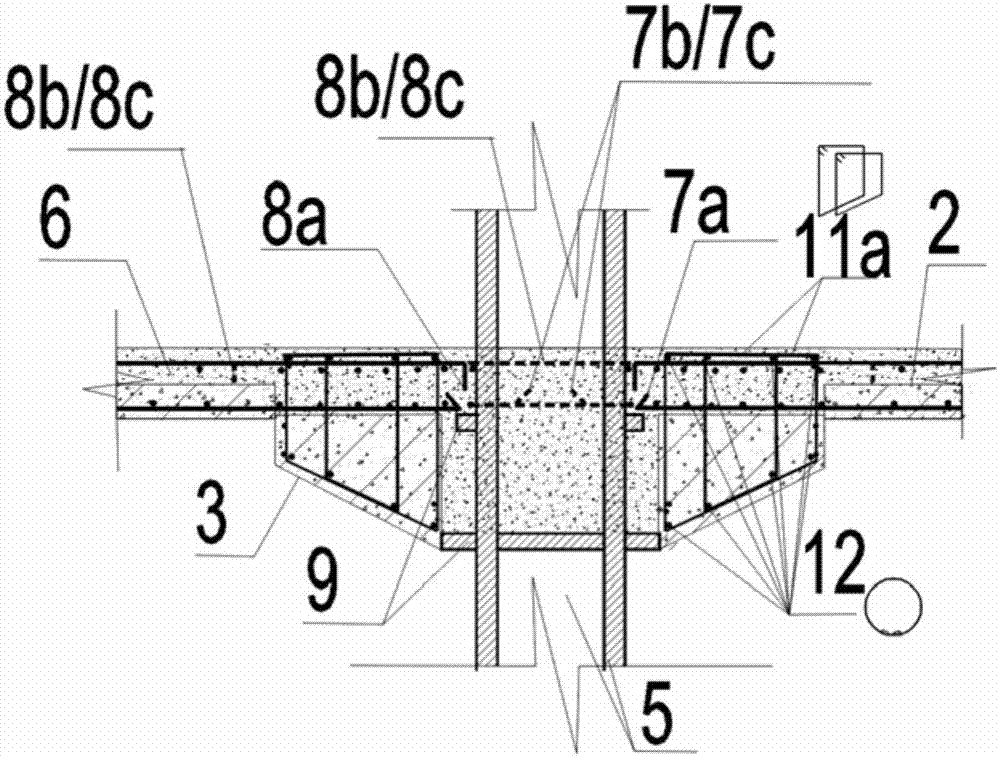

[0043] Figure 1-5 Shown: ( figure 1 The upper half and left half of the node represent the upper reinforcement of the node, the lower half and the right half represent the lower reinforcement of the node); the slab-column structure node 1 of the shaped steel column includes the shaped steel column 5, the prefabricated column cap 3, and the floor prefabricated component 2 (for the laminated floor prefabricated parts) and its connection joint surface, steel bars and post-cast concrete 6 (post-cast concrete requires the use of micro-expansion concrete with a grade higher than the strength of the connected prefabricated components); the plane of the joint is rectangular, and the direction of the edge of the rectangle In the same direction as the main axis of the slab-column structure, two shear rings 9 are arranged on the outer surface of the steel column 5 and welded on the outer periphery of the I-shaped steel, that is, the steel column 5, and the upper shear ring 9 is square s...

Embodiment example 2

[0053] Figure 6-10 Shown: ( Figure 6 The upper half and left half of the node represent the upper reinforcement of the node, the lower half and the right half represent the lower reinforcement of the node); the slab-column structure node 1 of the shaped steel column includes the shaped steel column 5, the prefabricated supporting plate 4, and the floor prefabricated component 2 (prefabricated floor slab for the overall thickness) and its connecting joint surface, steel bars and post-cast concrete 6; the joint plane is rectangular, and the direction of the side line of the rectangle is the same as the main axis direction of the slab-column structure. The ring 9 is welded on the outer periphery of the shaped steel column 5 of the square tube shape, and the shear ring 9 is a steel plate, which is welded on the outside of the shaped steel column 5 with a fillet weld ( Figure 7 Large sample diagram of the shear ring), the plane of the shear ring 9 is in the shape of a ring, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com