Surface pleat-removing equipment for coiled gray cloth

A gray cloth and rolling technology, which is applied in fabric surface trimming, textile and papermaking, mechanical cleaning, etc., can solve the problems of incomplete cleaning, machine wrinkle removal, low efficiency, etc., and achieve the effect of optimized and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

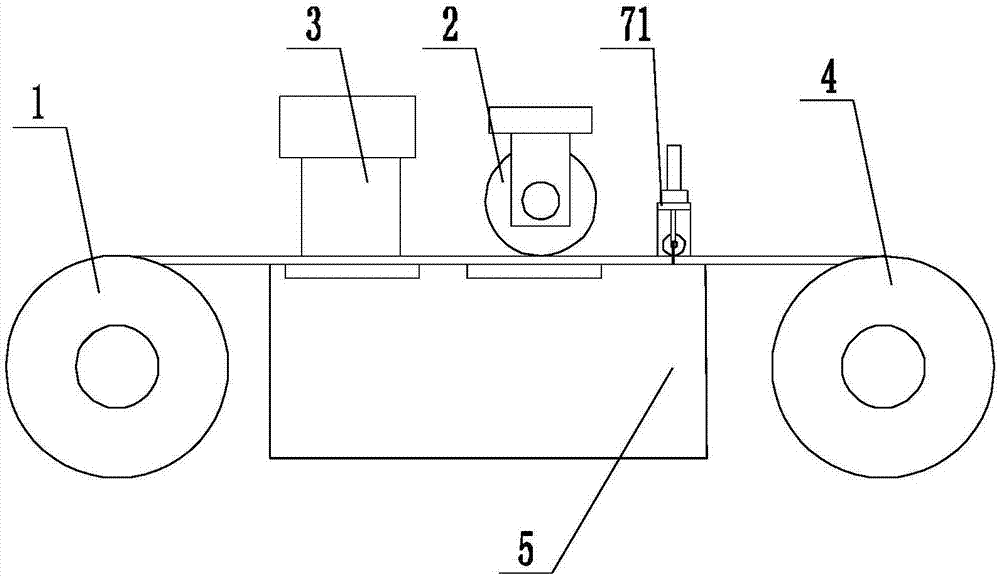

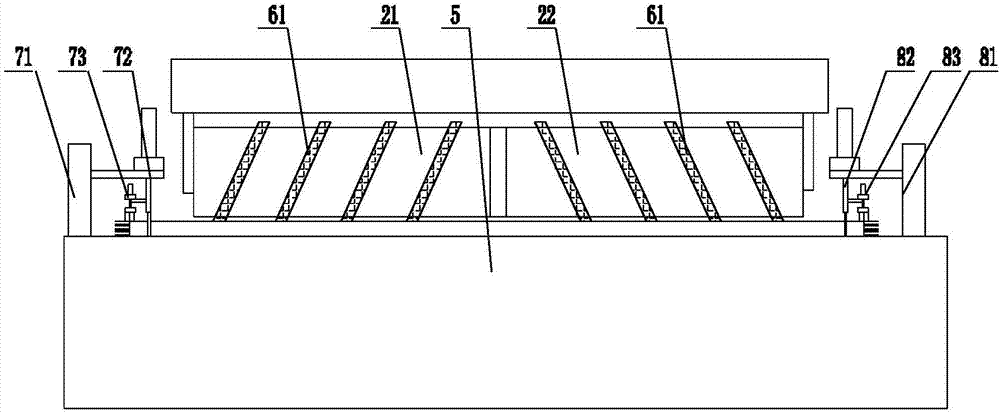

[0017] Such as figure 1 and 2 as shown, figure 1 It is a schematic structural view of a roll gray cloth surface wrinkle removal device proposed by the present invention, figure 2 It is another structural schematic diagram of a roll greige surface wrinkle removal equipment proposed by the present invention.

[0018] refer to figure 1 and 2 , a kind of roll greige surface wrinkle removal equipment that the present invention proposes, comprises: feeding device 1, wrinkle removal roller 2, steam device 3, material receiving device 4, support platform 5, heating device;

[0019] The feeding device 1 and the discharging device are respectively located on both sides of the support platform 5, and the top of the support platform 5 is provided with a first support surface and a second support surface arranged horizontally along the feeding direction;

[0020] The steam device 3 is located above the first supporting surface, and the bottom of the steam device 3 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com