A high-volume ceramic-metal layered composite material and its preparation method

A technology of metal composite materials and composite materials, which is applied in the field of high-volume ceramic-metal layered composite materials and its preparation, can solve the problems of disorder, organization with residual holes, and high content of metal phases, so as to improve performance and eliminate The effect of porosity defect and good toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

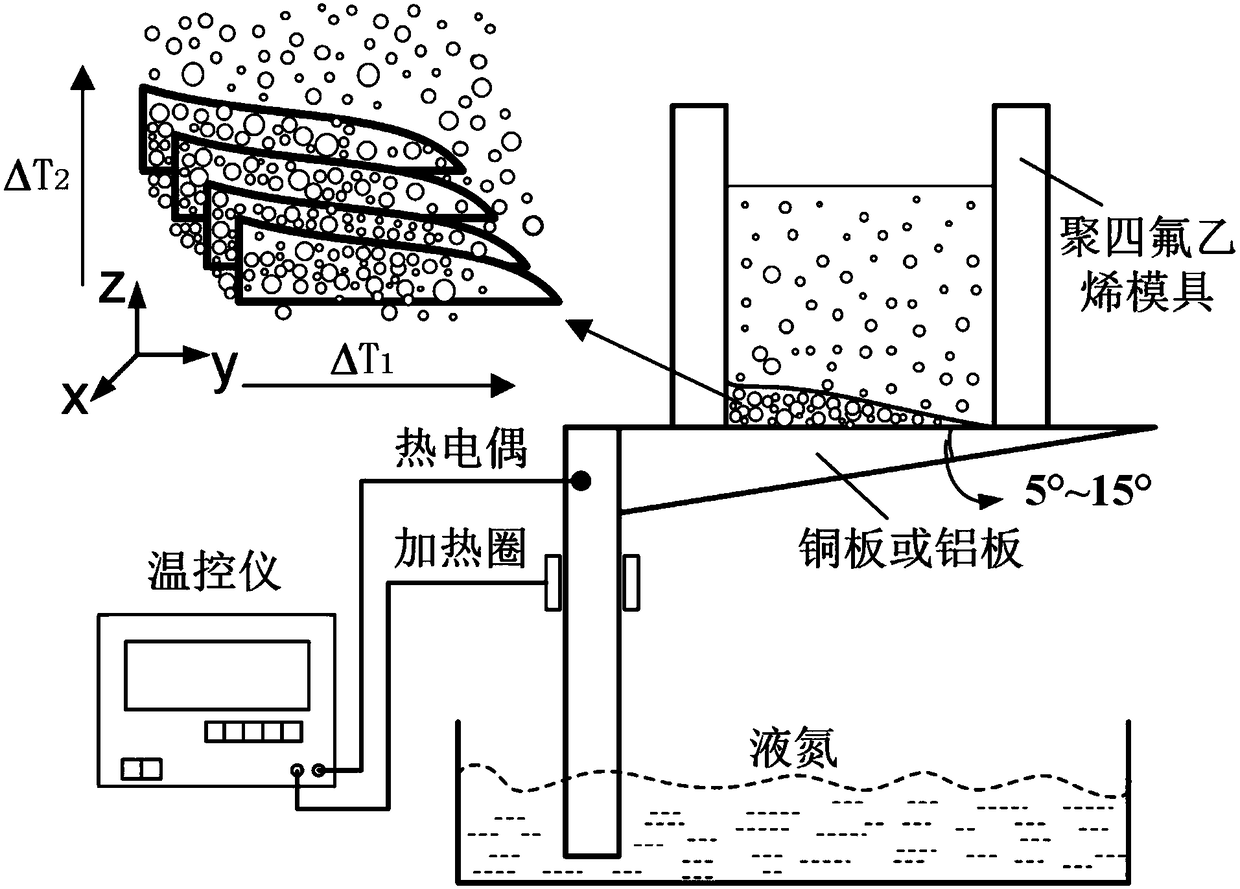

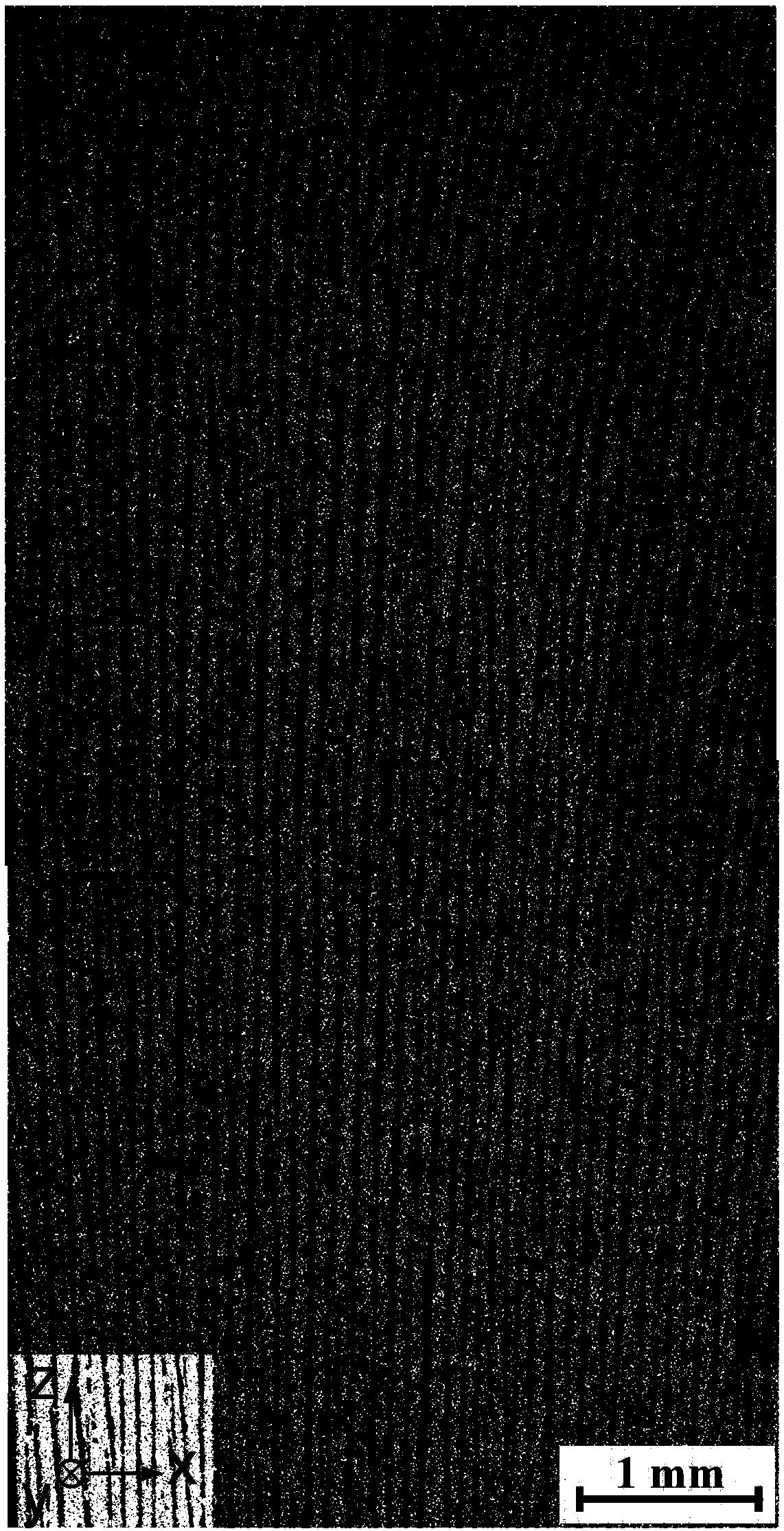

[0028] Will Al 2 o 3 Ceramic powder (D 50 =5μm, 99.9%) and deionized water are mixed at a volume ratio of 1:2.3, and a dispersant (polyammonium methacrylate, accounting for 1wt.% of the mass of the ceramic slurry) and a binder (polyvinyl alcohol, accounting for the ceramic slurry mass) are added 1wt.% of the slurry mass), then ball milled (speed 150 rev / min, ball milled for 8 hours) and defoamed for 20min to prepare an Al with an initial ceramic content of 30vol.%. 2 o 3 Ceramic slurry 200ml. Install the polytetrafluoroethylene mold on the wedge-shaped frozen copper plate, the plate length is 100mm, and the inclination angle is 5°. The mold is placed at a distance of 10mm from the thick end of the wedge-shaped frozen plate, and then the ceramic slurry is injected into the polytetrafluoroethylene mold. The thick end of the tube was cooled at a constant rate of 1°C / min from room temperature. After the frozen ceramic green body is removed from the mold, it is quickly put int...

Embodiment 2

[0032] Will Al 2 o 3 Ceramic powder (D 50 =2μm, 99.9%) and deionized water are mixed at a volume ratio of 1:4, and a dispersant (ammonium polymethacrylate, accounting for 1wt.% of the mass of the ceramic slurry) and a binder (polyvinyl alcohol, accounting for the ceramic slurry mass) are added 1wt.% of the slurry mass), then ball milled (speed 150 rev / min, ball milled for 8 hours) and defoamed for 20min to prepare an Al with an initial ceramic content of 20vol.%. 2 o 3 Ceramic slurry 200ml. Install the polytetrafluoroethylene mold on the wedge-shaped frozen copper plate, the plate length is 60mm, and the inclination angle is 10°. The mold is placed at a distance of 5mm from the thick end of the wedge-shaped frozen plate, and then the ceramic slurry is injected into the polytetrafluoroethylene mold. The thick end of the tube was cooled at a constant rate of 5°C / min from room temperature. After the frozen ceramic body is removed from the mold, it is quickly put into a freez...

Embodiment 3

[0036] Will Al 2 o 3 Ceramic powder (D 50 =500nm, 99.9%) and deionized water are mixed at a volume ratio of 1:4, and a dispersant (polyammonium methacrylate, accounting for 1wt.% of the mass of the ceramic slurry) and a binder (polyvinyl alcohol, accounting for the ceramic slurry mass) are added 1wt.% of the slurry mass), then ball milled (speed 150 rev / min, ball milled for 8 hours) and defoamed for 20min to prepare an Al with an initial ceramic content of 20vol.%. 2 o 3 Ceramic slurry 200ml. Install the polytetrafluoroethylene mold on the wedge-shaped frozen aluminum plate, the plate length is 80mm, and the inclination angle is 7.5°. The mold is placed 20mm away from the thick end of the wedge-shaped frozen plate, and then the ceramic slurry is injected into the polytetrafluoroethylene mold. The thick end is cooled at a constant rate of 1°C / min from room temperature. After the frozen ceramic green body is removed from the mold, it is quickly put into a -50°C freeze dryer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com