Method for stabilizing heavy metal lead in bottom mud by virtue of chlorapatite-loaded charcoal composite material

A chloroapatite and composite material technology, which is applied in biological sludge treatment, chemical instruments and methods, water pollutants, etc. High problems, to achieve clean and pollution-free practical application value, reduce bioavailability, stabilize the effect of heavy metal lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

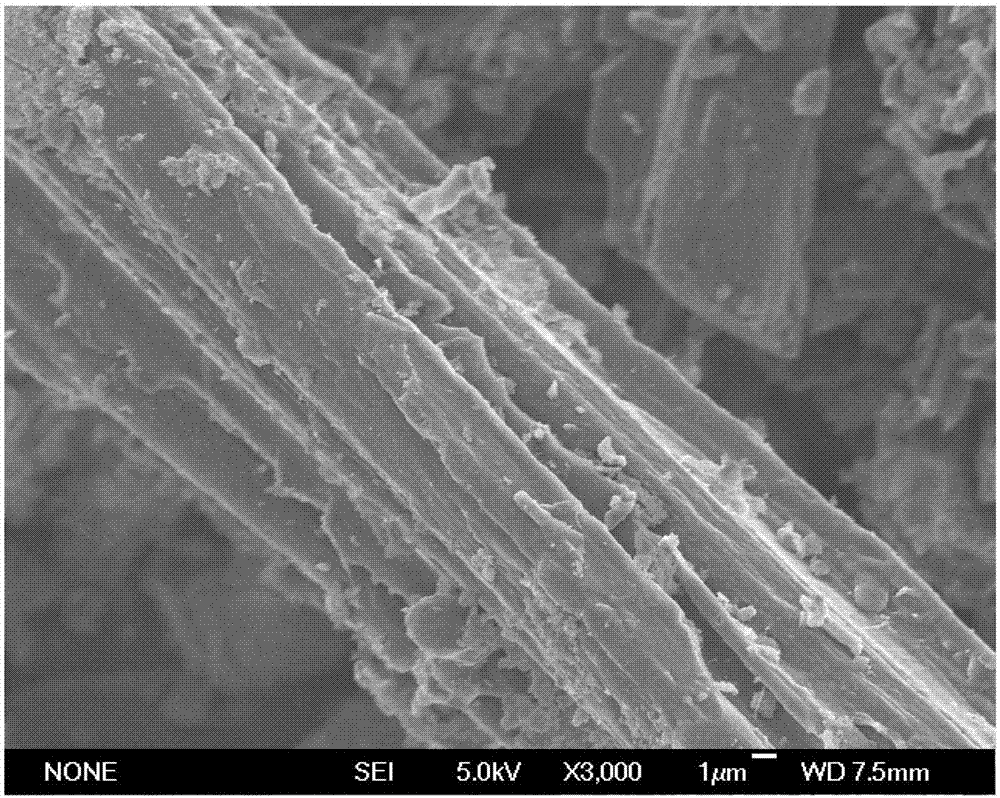

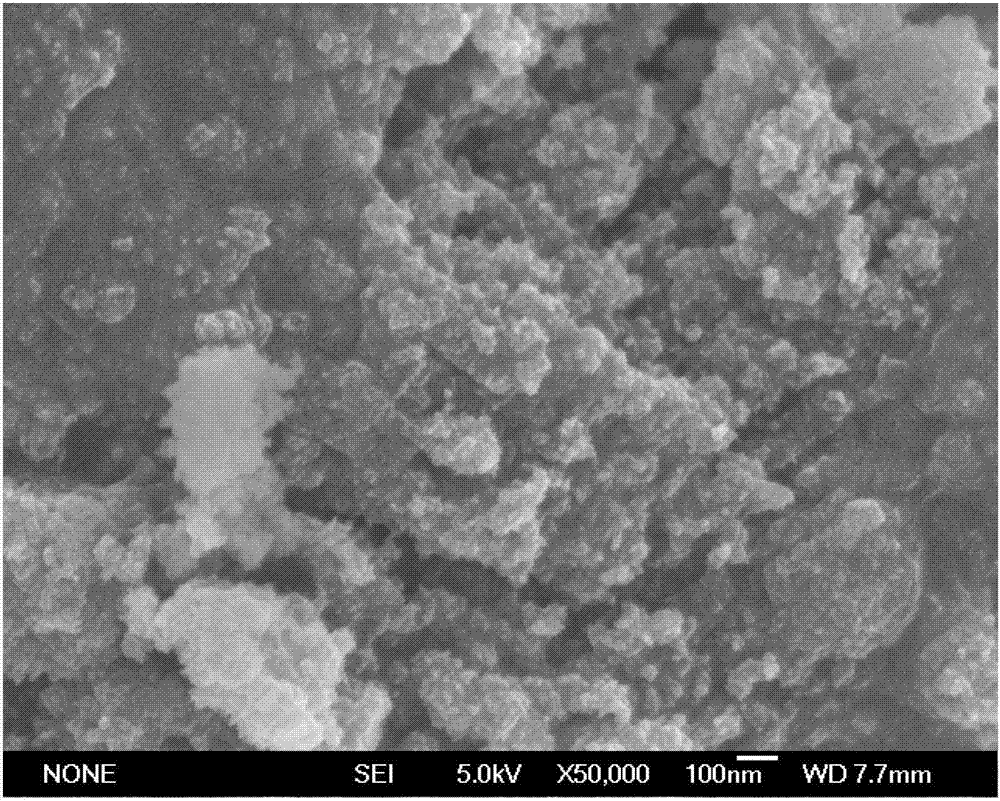

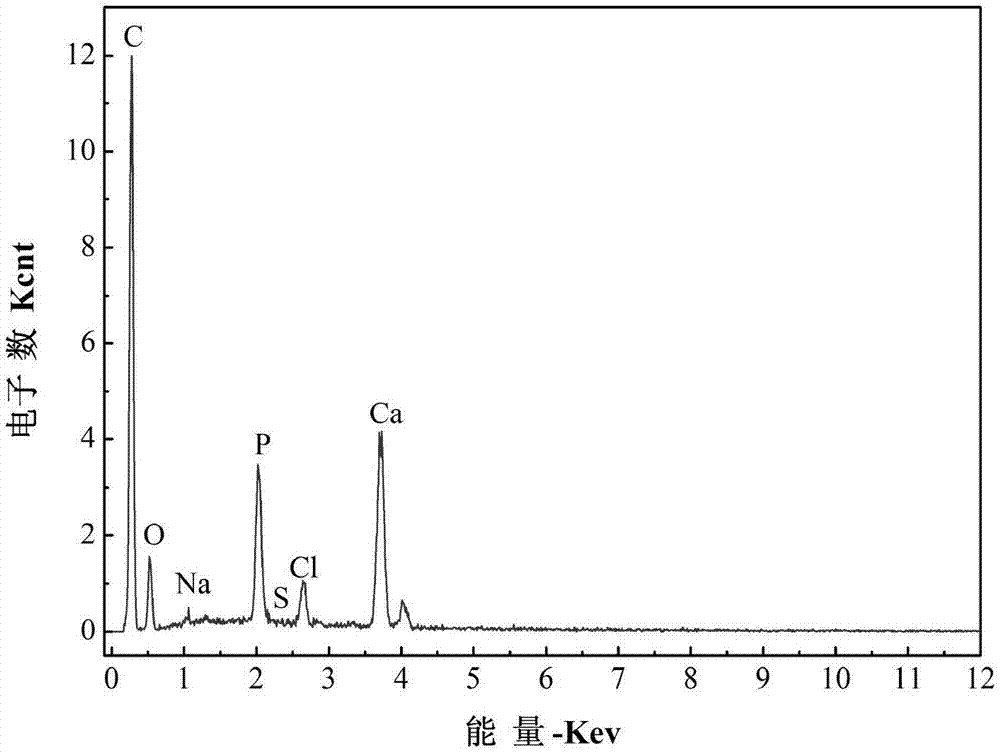

[0038] A method for stabilizing heavy metal lead in bottom mud by using a biochar composite material loaded with chloroapatite includes the following steps:

[0039] The lead-containing bottom mud is air-dried, ground, and passed through a 100-mesh sieve to obtain the crushed lead-containing bottom mud with a particle size of ≤150μm, a pH of 7.98, and the heavy metal lead in weak acid extraction state (F1), reducible state (F2), The content of oxidizable state (F3) and residue state (F4) were 8.2%, 11.1%, 60.5%, and 20.2%, respectively. Take 0.3g of the biochar composite material loaded with chloroapatite and 5mL of ultrapure water, add 0.5g of the above crushed lead-containing bottom sludge and mix evenly, shake and react for 30d at 25℃, complete the treatment of lead-containing bottom sludge Stable processing. The BCR continuous extraction method was used to determine the content of the four forms of heavy metal lead in the bottom mud. The detection results are listed in Table...

Embodiment 2

[0055] A method for stabilizing heavy metal lead in bottom mud by using a biochar composite material loaded with chloroapatite includes the following steps:

[0056] The lead-containing bottom mud is air-dried, ground, and passed through a 100-mesh sieve to obtain the crushed lead-containing bottom mud with a particle size of ≤150μm, a pH of 7.98, and the heavy metal lead in weak acid extraction state (F1), reducible state (F2), The content of oxidizable state (F3) and residue state (F4) were 8.2%, 11.1%, 60.5%, and 20.2%, respectively. Take 0.3g of the biochar composite material loaded with chloroapatite and 5mL of ultrapure water, add 0.5g of the pulverized lead-containing bottom sludge and mix uniformly, shake and react for 30 days at 25°C to complete the treatment of the lead-containing bottom sludge. Stable processing. The BCR continuous extraction method was used to determine the content of the four forms of heavy metal lead in the bottom mud. The detection results are lis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com