Method for achieving unmanned crown block micro-swing control

A technology of cranes and carts, which is applied in the field of micro-swing control of unmanned cranes, and can solve problems such as the inability to realize precise stacking of steel coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

[0042] A method for realizing the micro-swing control of an unmanned crane, comprising the following steps:

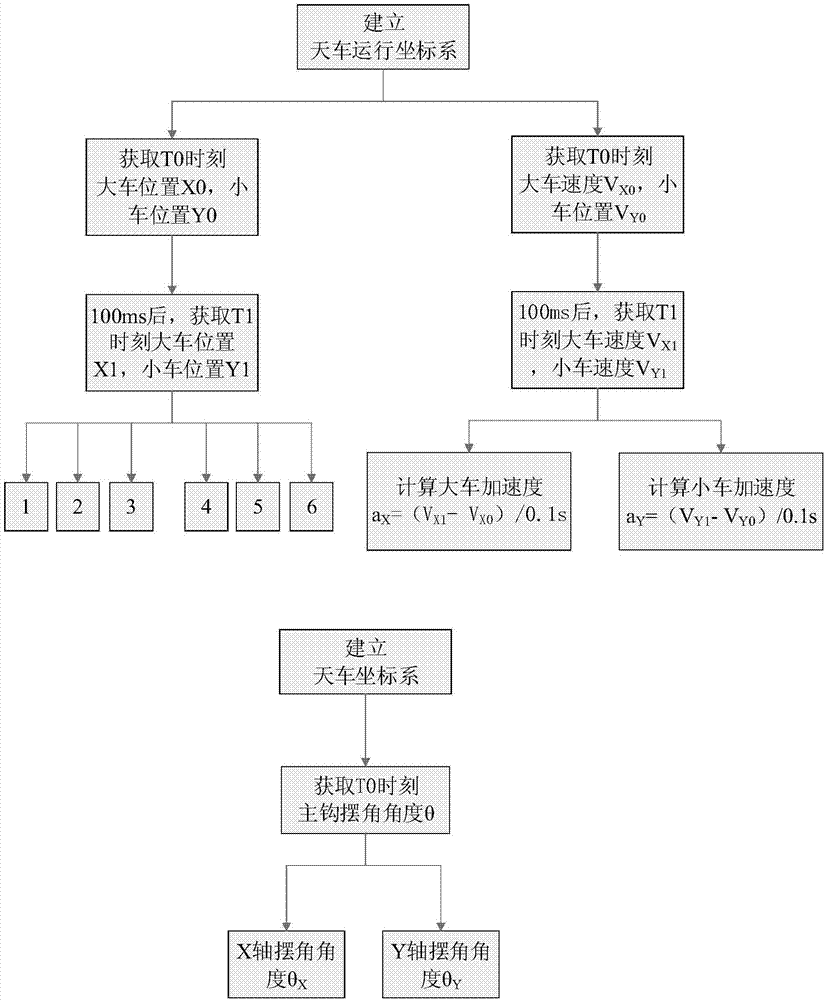

[0043] A: Establish the coordinate system of the crane operation, and establish the coordinate system of the swing angle of the crane;

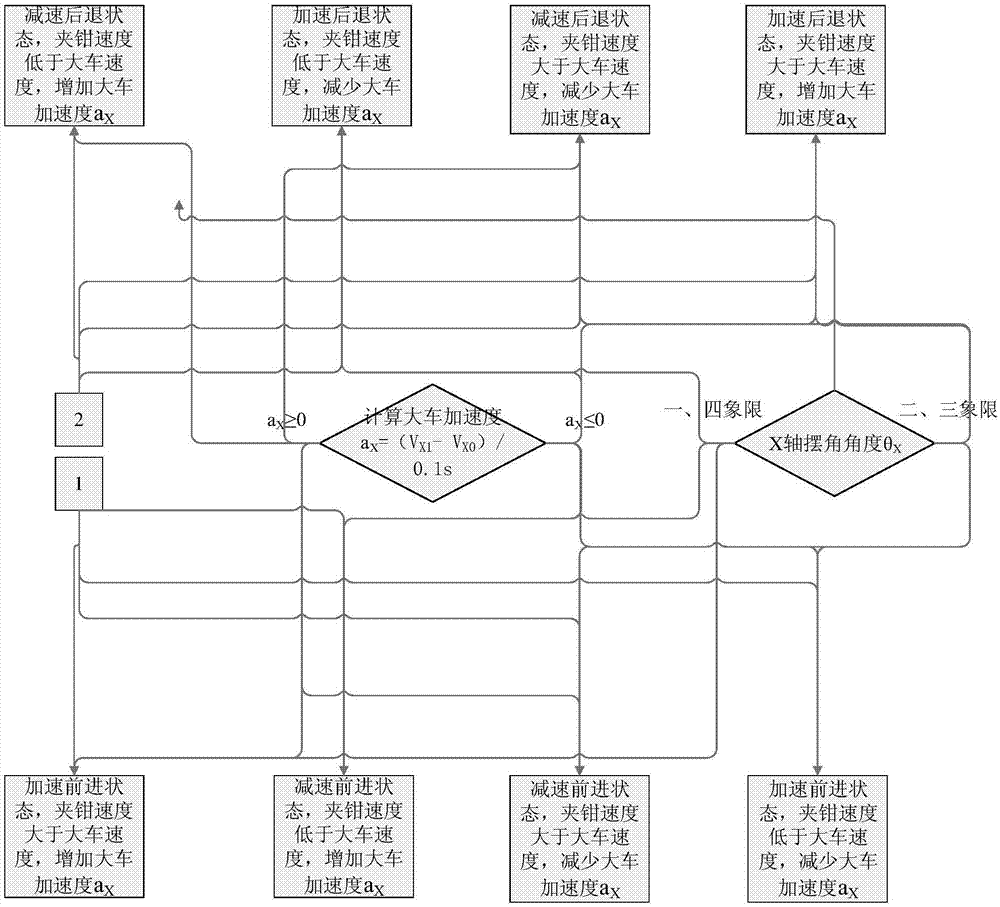

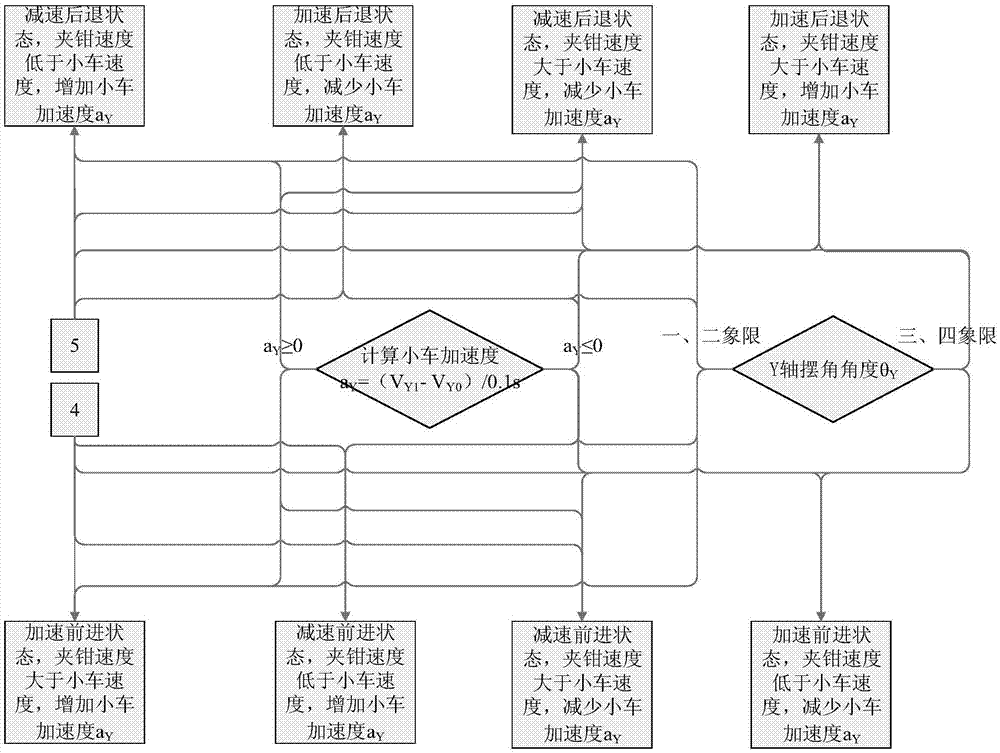

[0044] B. By decomposing the coordinate system of the crane movement and the coordinate system of the swing angle of the crane, find out the relationship between the speed, acceleration, running direction and swing angle direction of the crane, and analyze and analyze the projection of the swing angle in different quadrants Swing angle detection realizes the proportional increase and decrease of the acceleration of the crane and the trolley, completes the swing angle control of the crane and the trolley, and turns the complicated swing angle control of the crane into a simple speed control of the crane.

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com