Packing and transport device and method for pipe sections for chemical modular prefabrication

The technology of a transportation device and transportation method is applied in the field of chemical modularized prefabricated pipe section packaging and transportation equipment, which can solve the problems of unusable lifting belts, collision between pipe sections and pipe sections, and easy damage to the surface of pipe sections, so as to facilitate the assembly of transportation frames and avoid Collision, avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

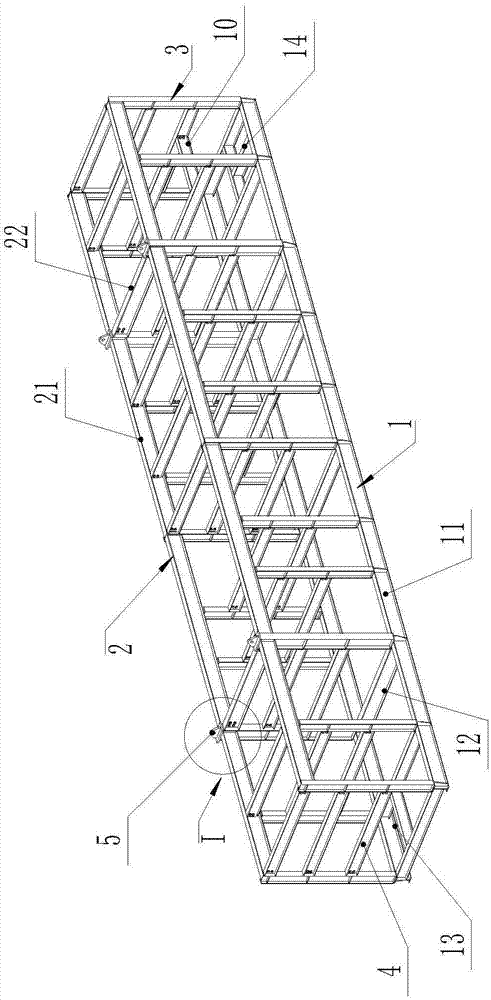

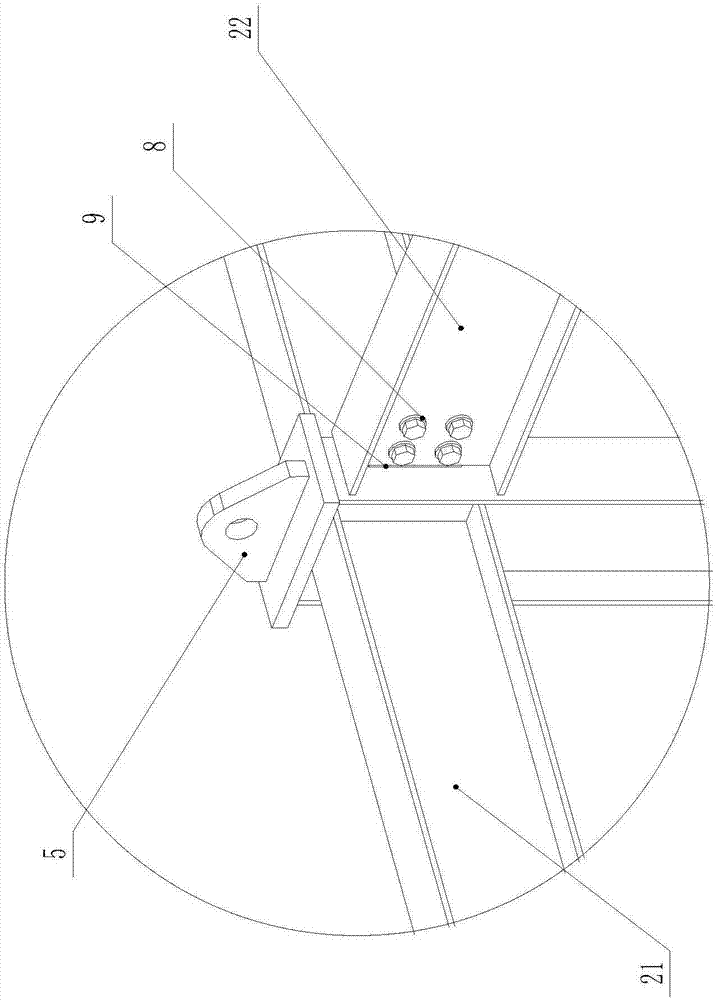

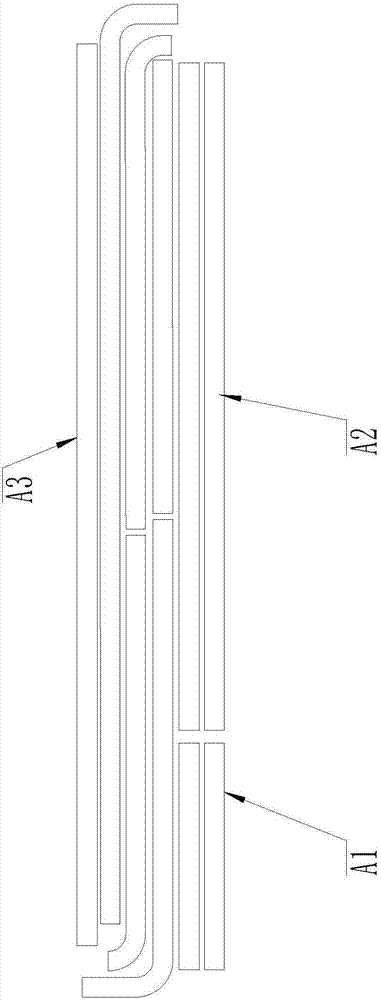

[0043] Such as Figure 1 to Figure 8 As shown, a pipe segment packaging transportation device for chemical modular prefabrication includes a transportation frame, and the transportation frame includes a lower frame 1, an upper frame 2 and a vertical beam 3 connecting the lower frame 1 and the upper frame 2, and the lower frame 1 It includes a rectangular lower frame 11, which is welded by I-shaped steel, and several parallel lower beams 12 are installed in the lower frame 11, and the lower beams 12 and the lower frame 11 constitute There are a plurality of rectangular areas, and at least one lower partition longitudinal beam 13 is arranged in the rectangular area at both ends of the lower surround frame 11, and a lower partition beam 14 is fixed in the rectangular area at the end of the lower surround frame 11. The lower partition The beam 14 is fixed between the lower partition longitudinal beam 13 and the lower wall frame 11 . The lower partition longitudinal beam 13, the l...

Embodiment 2

[0049] A method for packaging and transporting pipe sections for chemical modular prefabrication, the packaging and transport method uses a packaging and transport device, which includes the following steps:

[0050] A. Decompose the chemical module into several pipe sections;

[0051] B. Use 3D software to draw the 1:1 pipe section model corresponding to all pipe sections. Each pipe section model includes pipe section support, pipe section insulation, pipe section material, size, and weight information. The 3D software can choose currently commonly used drawing software, such as AutoCAD;

[0052] C. Classify all the pipe sections in advance according to the material of the pipe sections. The pipe sections of the same material belong to the same category; generally in the production of chemical modules, the materials of the pipe sections are roughly divided into carbon steel and stainless steel, so the two must be placed separately to avoid mutual pollute.

[0053] D. Classi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com