Three-dimensional preformed composite fiber and machining process thereof

A composite fiber and processing technology, applied in the textile field, can solve problems such as poor stability and low product qualification rate, and achieve the effects of enhancing integrity and stability, improving interlayer performance and impact damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

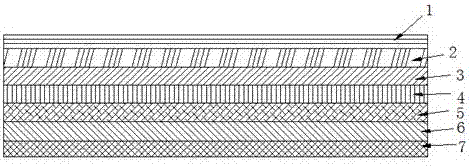

[0019] see as figure 1 As shown, the technical solution adopted in this specific embodiment is: it comprises 0 ° layer 1, chopped yarn layer 2, +45 ° layer 3, 90 ° layer 4, diversion sandwich layer 5, -45 ° layer 6, surface Layer 7; the 0° layer 1, the chopped yarn layer 2, the +45° layer 3, the 90° layer 4, the diversion sandwich layer 5, the -45° layer 6, and the surface layer 7 are arranged in sequence from top to bottom.

[0020] Further, the 0° layer 1, +45° layer 3, 90° layer 4, and -45° layer 6 are reinforced fiber material layers, which can be high-performance glass fiber, carbon fiber, aramid fiber, etc.

[0021] Further, the air-guiding sandwich layer 5 is an organic fiber needle-punched or chemically bonded felt.

[0022] Further, the chopped strand layer 2 is high performance glass fiber chopped strand.

[0023] Further, the surface layer 7 is thin glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com