PC component automatic production line and production process

A technology for automated production lines and components, applied in manufacturing tools, ceramic molding workshops, auxiliary molding equipment, etc., can solve the problems of raw material waste, long construction period, unstable quality, etc., to reduce labor intensity, improve production efficiency, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

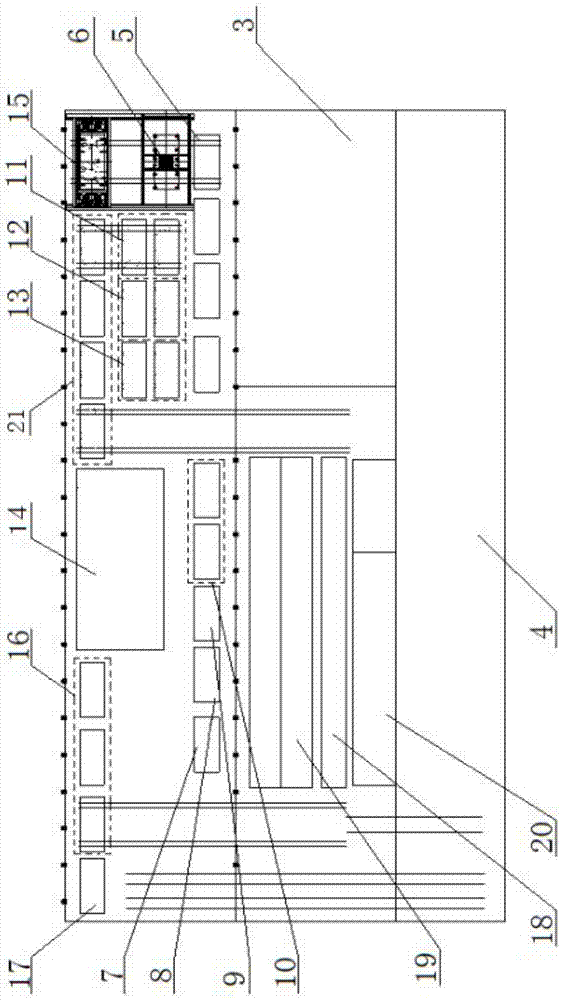

[0018] Such as figure 1 and figure 2 As shown, a PC component automatic production line of the present invention includes a special-shaped component production area 1, a laminated board, an outer wall, and an inner wall production area 2 arranged in front of the special-shaped component production area 1, and located on the right side of the special-shaped component production area 1 The cage bar production area 3, the component yard area 4 behind the special-shaped component production area 1, the special-shaped component production area 1, the cage bar production area 3, the component stockyard area 4, and the laminated board, outer wall, and inner wall production area 2 are connected by the track of the transport component mold table, and the component mold table is processed by each station to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com