Pulse current and vibration matched feeding device

A technology of pulse current and feeding device, which is applied in the direction of accessory devices, electric processing equipment, power supply circuits, etc., can solve the problems of small gap processing short circuit, affecting processing accuracy, stray corrosion, etc., to reduce stray corrosion and improve precision , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

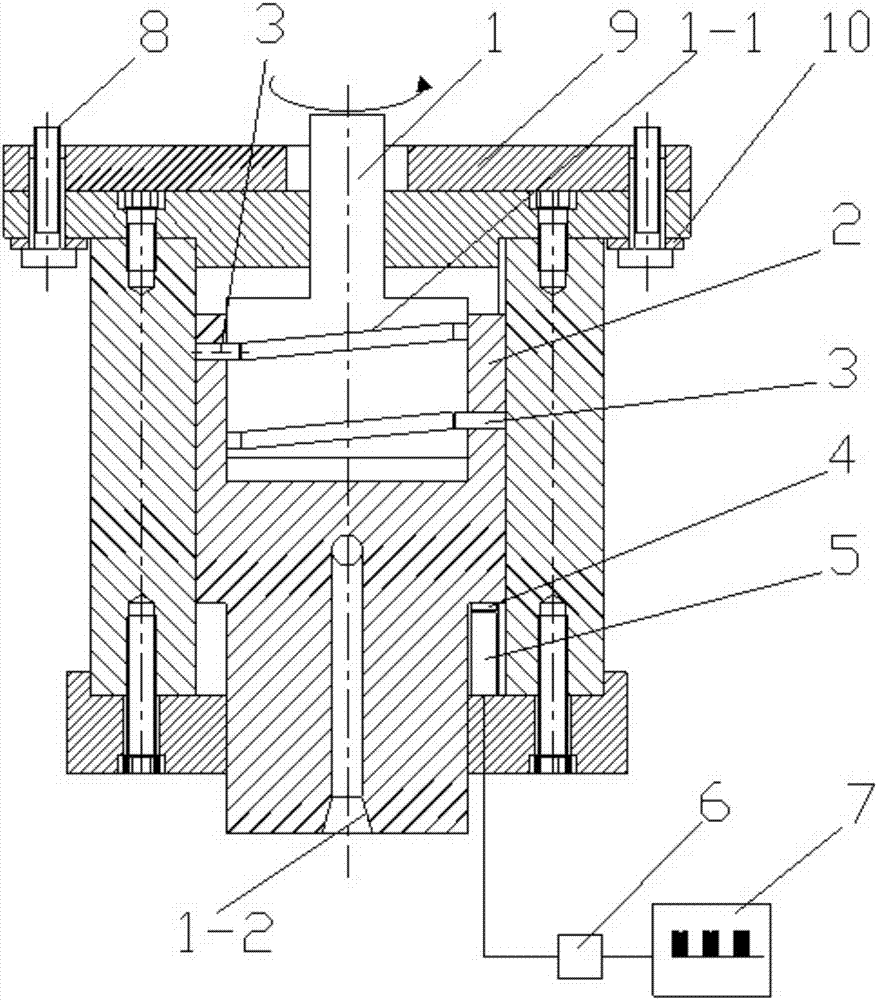

[0019] The present invention is a pulse current and vibration matching feeding device, such as figure 1 shown.

[0020] Cam 1 and slider 2 form a mechanical vibration mechanism, cam 1 rotates to drive slider 2 to vibrate up and down, cylindrical cam 1 is processed with 2 identical cam profile curves 1-1, and slider 2 is equipped with 2 cylindrical pins 3. Make the slider 2 stressed symmetrically. The taper hole 1-2 on the slider 2 is used for positioning when installing the cathode and sealing of the internally sprayed electrolyte. The bolts 8 are used to install the device to the beam of the electrolytic machining machine tool. The first metal damping material 9 and the second metal damping material 10 can isolate vibration and eliminate the influence of mechanical vibration on the electrolytic machining machine tool. A permanent magnet 4 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com