A kind of adsorption material and preparation method thereof

A technology of adsorption materials and mixed slurry, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of environmental pollution, waste of resources, etc., and achieve the effect of simple preparation, easy utilization, and good adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

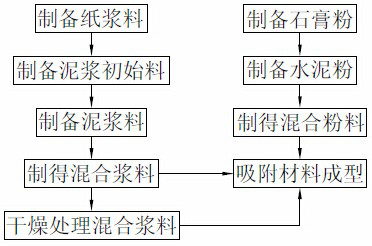

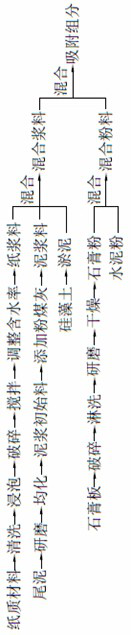

Method used

Image

Examples

Embodiment 1

[0033] An adsorption material includes an adsorption component prepared by mixing a mixed slurry and a mixed powder, the mixed slurry includes paper slurry, and the mixed powder includes gypsum powder.

[0034] One kind of adsorption material of this embodiment, through the adsorption component prepared by mixing paper slurry and gypsum powder, utilizes the porous characteristics of paper slurry and the adsorption of water, so that the prepared adsorption component has better adsorption , the gypsum particles of gypsum powder are used to increase the porosity in the paper slurry, and the gypsum powder has a certain gelation effect after meeting water, so that the prepared adsorption component is easy to shape and use, and the gypsum powder has a certain strength after drying, so that The adsorption component is more convenient to use and has a wide range of applications. According to the actual situation, cement powder that also has the effect of gelling adsorption can be used ...

Embodiment 2

[0039] An adsorption material in this embodiment has the same components as in Embodiment 1, except that the adsorption slurry includes paper slurry and mud slurry, and the slurry material is made from tailings collected after cleaning building aggregates.

[0040] One kind of adsorption material of this embodiment adopts the adsorption component prepared by mixing paper slurry material and mud slurry material, adopts tailing mud collected after cleaning building aggregates as mud slurry material, and utilizes the good gelling effect of tail mud to combine with paper The combination of materials can maintain the pores formed by the paper material after the tailings are dried, promote the adsorption properties of the paper pulp, and also provide effective environmental protection for the discarded tailings at the construction site, avoiding resource waste and environmental pollution.

[0041] Preferably, the parts by weight of the raw materials of each component in the mixed slu...

Embodiment 3

[0044] A kind of adsorption material of this embodiment is identical with embodiment 2 components, difference is: described mixed slurry comprises paper slurry and mud slurry and sludge, and described paper slurry is made of paper material, and described mud slurry is cleaned by It is obtained from tailings collected after building aggregates, and the sludge is made of diatomaceous earth.

[0045] A kind of adsorption material of this embodiment is prepared by mixing the mixed slurry made of paper slurry, mud slurry and silt, and mixed with the mixed powder made of gypsum powder and / or cement powder to prepare the adsorption component. The water absorption effect and the characteristics of irregular pores are easy to form after stacking, so that the prepared adsorption components form porous characteristics, and have good adsorption characteristics for water or toxic gases. Using the good gelation of tailings, it is compatible with paper materials. Cooperate, maintain the pore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com