A garment processing equipment

A kind of processing equipment and clothing technology, applied in the direction of sewing tools, measuring devices, force/torque/power measuring instruments, etc., can solve the problems of lower authenticity rate, influence of manufacturer's image, and poor quality, so as to save production costs , enhance the corporate image and increase the authenticity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

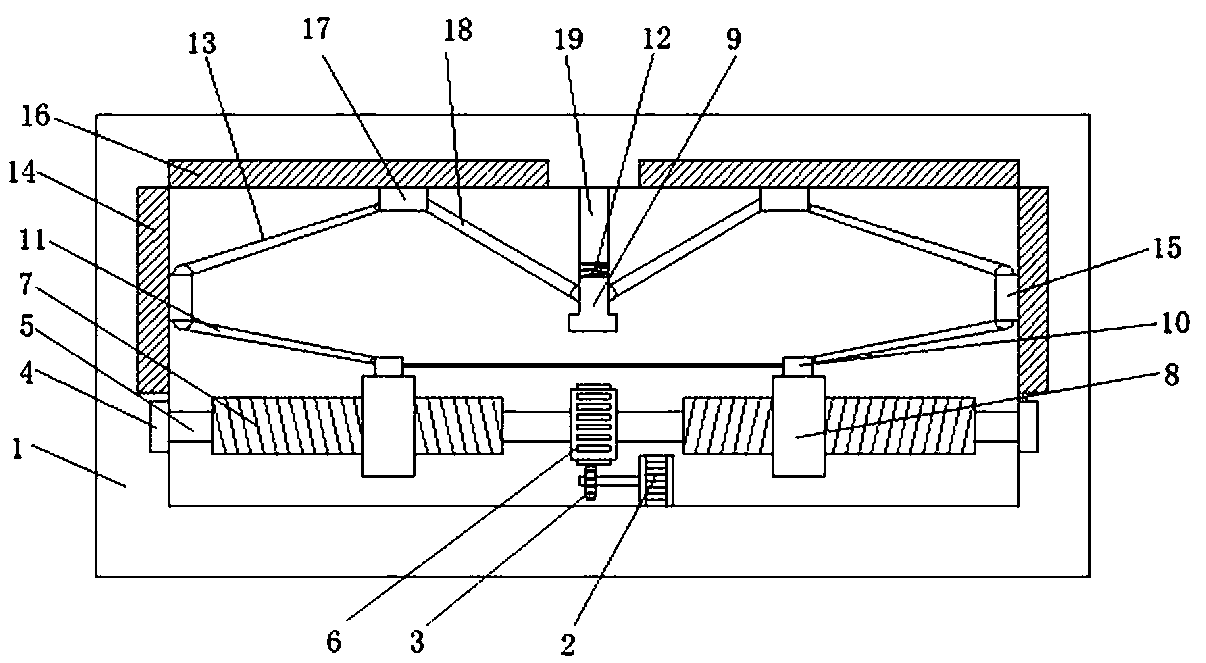

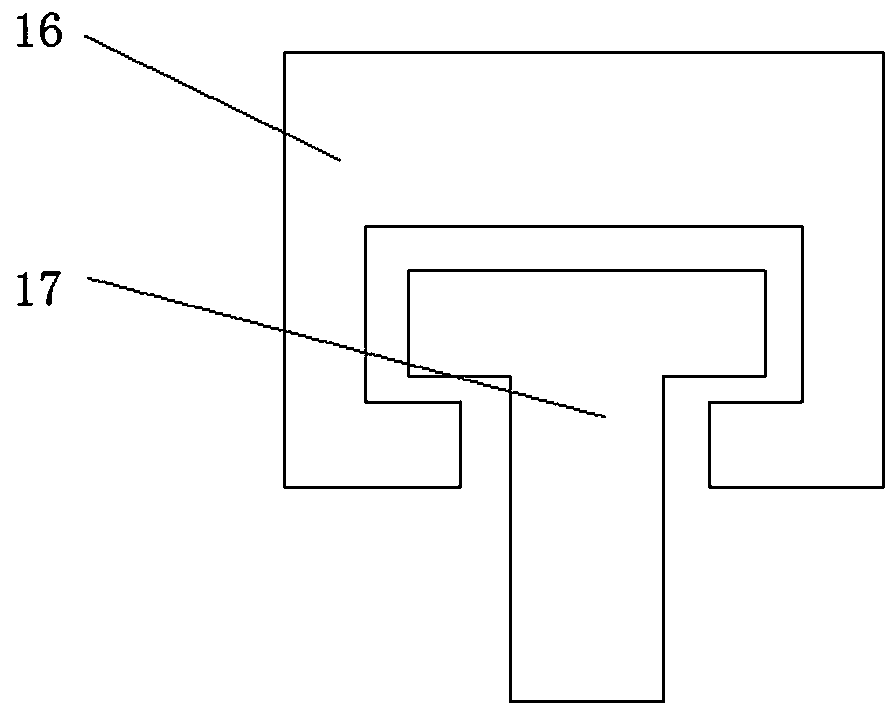

[0016] Reference Figure 1-2 , A clothing processing equipment, including a housing 1, the housing 1 is made of stainless steel alloy at the bottom of the housing 1 is fixed with a drive motor 2, the output shaft of the drive motor 2 is installed with a first gear 3, the housing 1 sets of opposite The inner wall is symmetrically provided with bearings 4, and a rotating shaft 5 is connected between the two sets of bearings 4, and the rotating shaft 5 is connected to the inner ring of the bearing 4, a second gear 6 is installed in the middle of the rotating shaft 5, and the second gear 6 is connected to the first Gear 3 meshes, screw rods 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com