Multi-angle display mechanism for automatic detection of outer surface of battery stainless steel casing

An automatic detection, stainless steel technology, applied in the direction of sorting, etc., can solve the problems of many errors, high cost, difficult to form batches, etc., and achieve the effect of simple structure, convenient detection, and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Corresponding reference characters indicate corresponding parts throughout the views of the drawings.

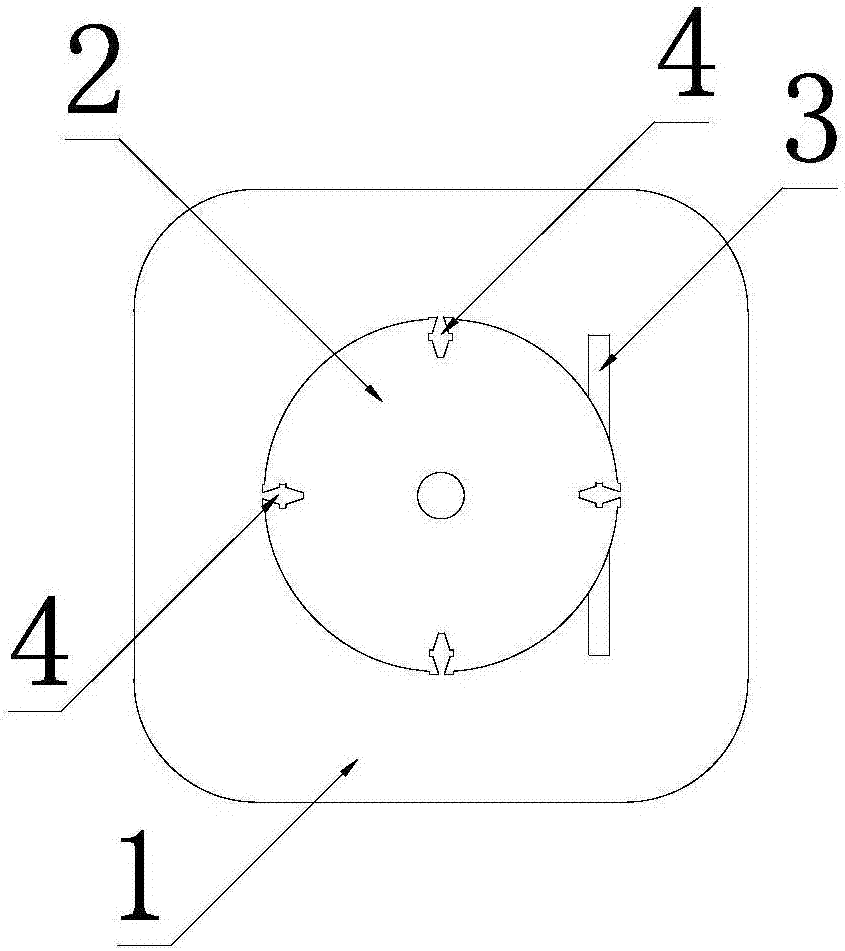

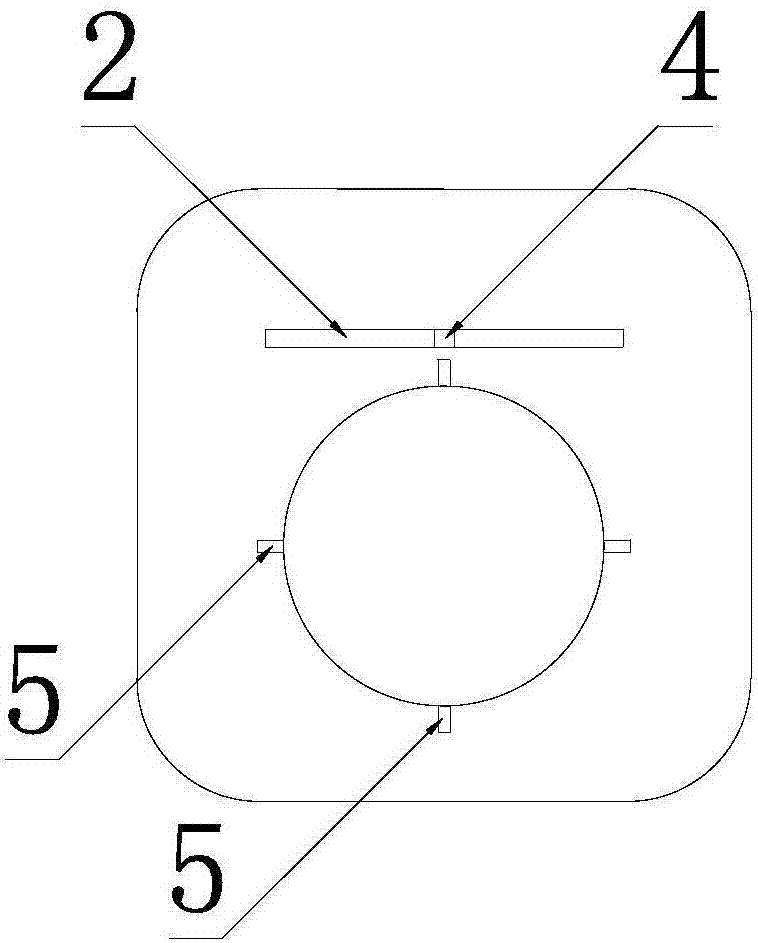

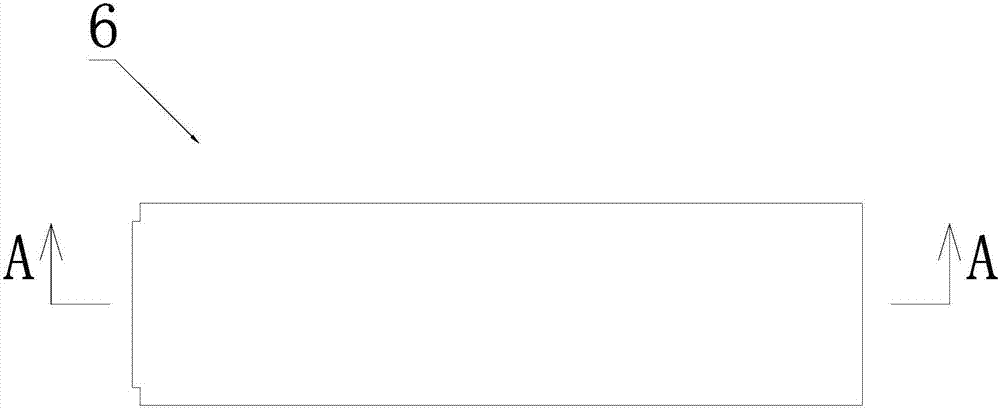

[0025] A multi-angle display mechanism for automatic detection of the outer surface of a battery stainless steel case, comprising a base 1, an outer and inner bottom display turntable 2 and a side display turntable 3 arranged on the base 1, and an outer and inner bottom display turntable 2 Set more than two battery stainless steel case side clamps 4 (used to clamp the side of the battery stainless steel case, so that the end face of the battery stainless steel case is exposed for testing), and the number of side display turntables 3 is more than two The battery stainless steel casing is sleeved with shaft 5 (the battery stainless steel casing is sleeved with shaft 5 as a rotating shaft), which can display the outer bottom, inner bottom and side of the battery stainless steel casing 6 in all directions, and can easily detect the appearance of the outer surface of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com