Fireproof watertightness type pre-branched magnesium oxide cable and installation method thereof

A pre-branched, magnesium oxide technology, used in cable installation, cable joints, cable accessories, etc., can solve the problems of non-refractory service life, difficult sealing, difficult connection, etc., to achieve good firmness, good fire resistance, Good water tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

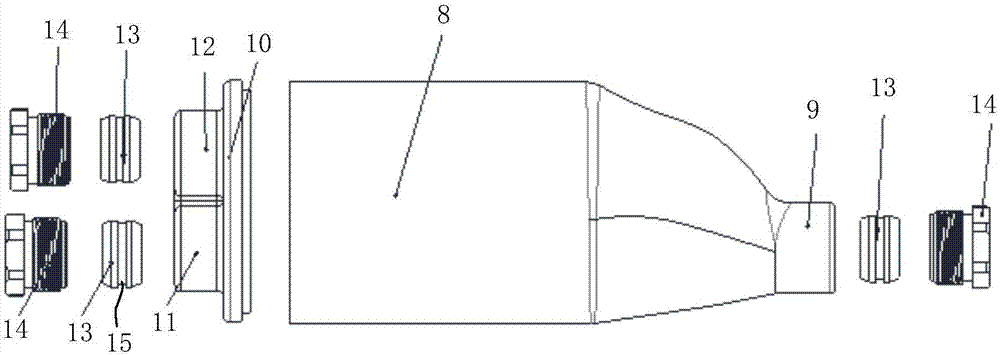

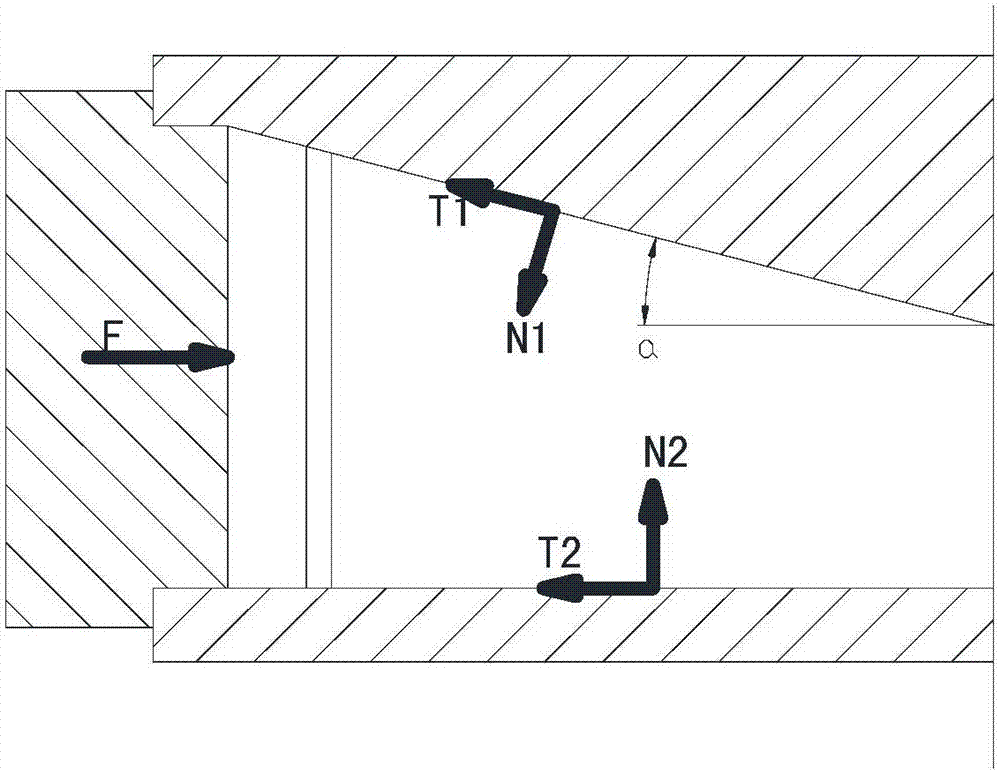

[0024] figure 1 It is a structural schematic diagram of a fire-proof water-tight type pre-branched magnesium oxide cable of the present invention; figure 2 It is a structural schematic diagram of the inner conductor connector of the fireproof and watertight type pre-branched magnesium oxide cable of the present invention.

[0025] See figure 1 and figure 2 , The fireproof watertight type pre-branched magnesium oxide cable provided by the present invention is composed of a conductor connector 1 and a sheath connecting body 8 . The conductor connector 1 is shaped by casting the blank material of copper material. One end forms the main cable inlet 2, and the other end forms the main cable outlet 3 and the branch cable 4. The three insertion ports are The head is externally threaded, and one or more press-fit sheets 5 are arranged between the inner si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com