Online quick calculation method for combustion efficiency of coal-fired boilers

A combustion efficiency, coal-fired boiler technology, applied in the field of boilers, can solve the problems of guidance, long detection time of ash carbon content, boiler changes, etc., and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

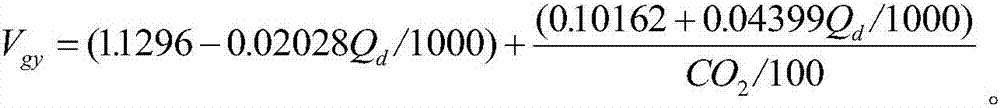

[0030] The online rapid calculation method of the combustion efficiency of the coal-fired boiler of the present invention realizes the rapid acquisition of the combustion efficiency of the coal-fired boiler of the power station and the coal-fired boiler of the industry, and provides a scientific basis for good operation regulation of the boiler. The formula for calculating the combustion efficiency of a boiler is as follows:

[0031] η=100-q 3 -q 4

[0032] Where η represents the combustion efficiency of the boiler, %; q 3 Indicates the percentage of heat lost by incomplete combustion of boiler gas to the heat input, %; q 4 Indicates the percentage of the heat lost by incomplete combustion of boiler solids to the heat input, %. In order to realize the rapid calculation of the combustion efficiency of coal-fired boilers, the present invention simplifies the calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com