an air compressor

A technology of air compressors and cylinders, which is applied in the field of air compressors with vibration-reducing and waterproof functions. It can solve the problems of poor thermal conductivity of wear-resistant materials such as graphite, small spaces, large noise and vibration, and achieve waterproof and vibration-reducing stability. Reliable, improved heat dissipation efficiency, good thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

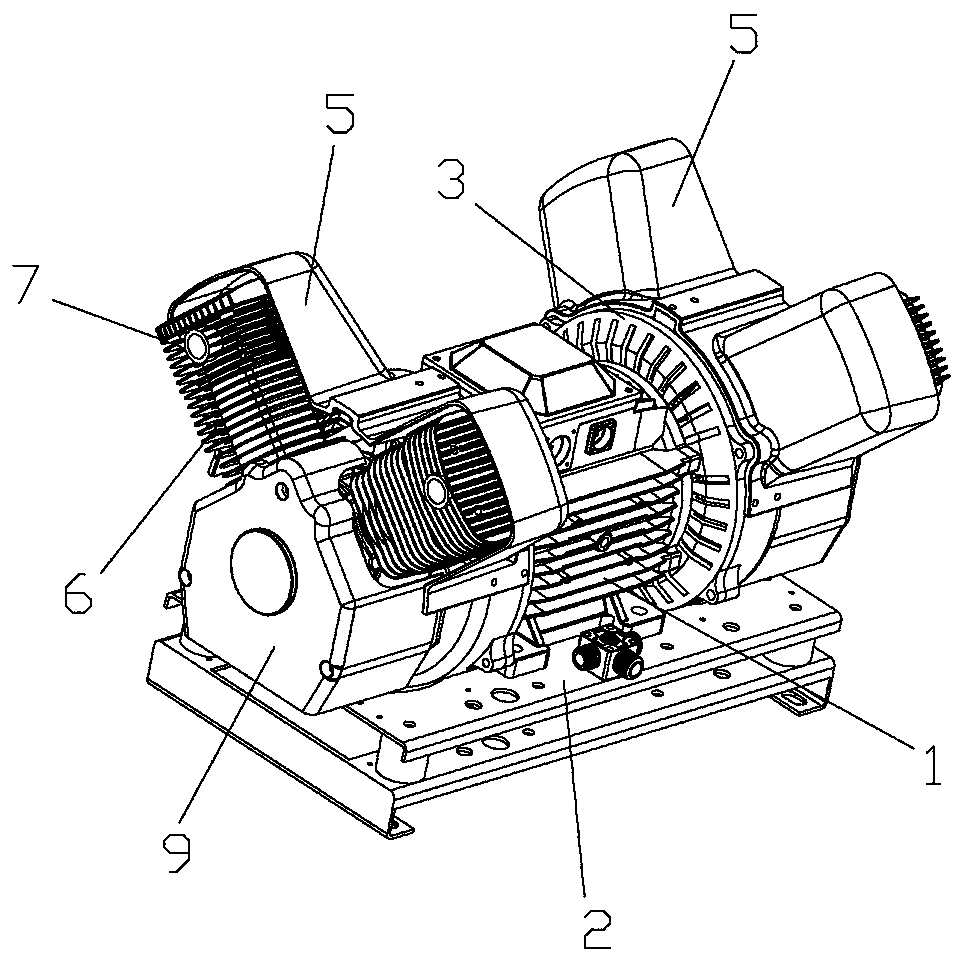

[0024] Such as Figure 1-6 As shown, an air compressor includes a motor 1, a casing 4, a cylinder 6, a valve plate, a cylinder head 7 and a base 2, the cylinder 6 is connected to the cylinder head 7, a valve plate is set between the cylinder 6 and the cylinder head 7, and the box A crank 41 is arranged in the body 4, and the crank 41 is connected to the output shaft of the motor 1. The output end of the crank 41 is connected to the piston device 51 inside the cylinder 6 through the connecting rod 42. It is characterized in that: the output shaft of the motor 1 A cooling fan device 3 coaxially arranged with the crank 41 is also connected to the top, and a wind guide cover 5 is arranged between the cooling fan device 3 and the cylinder and the cylinder head.

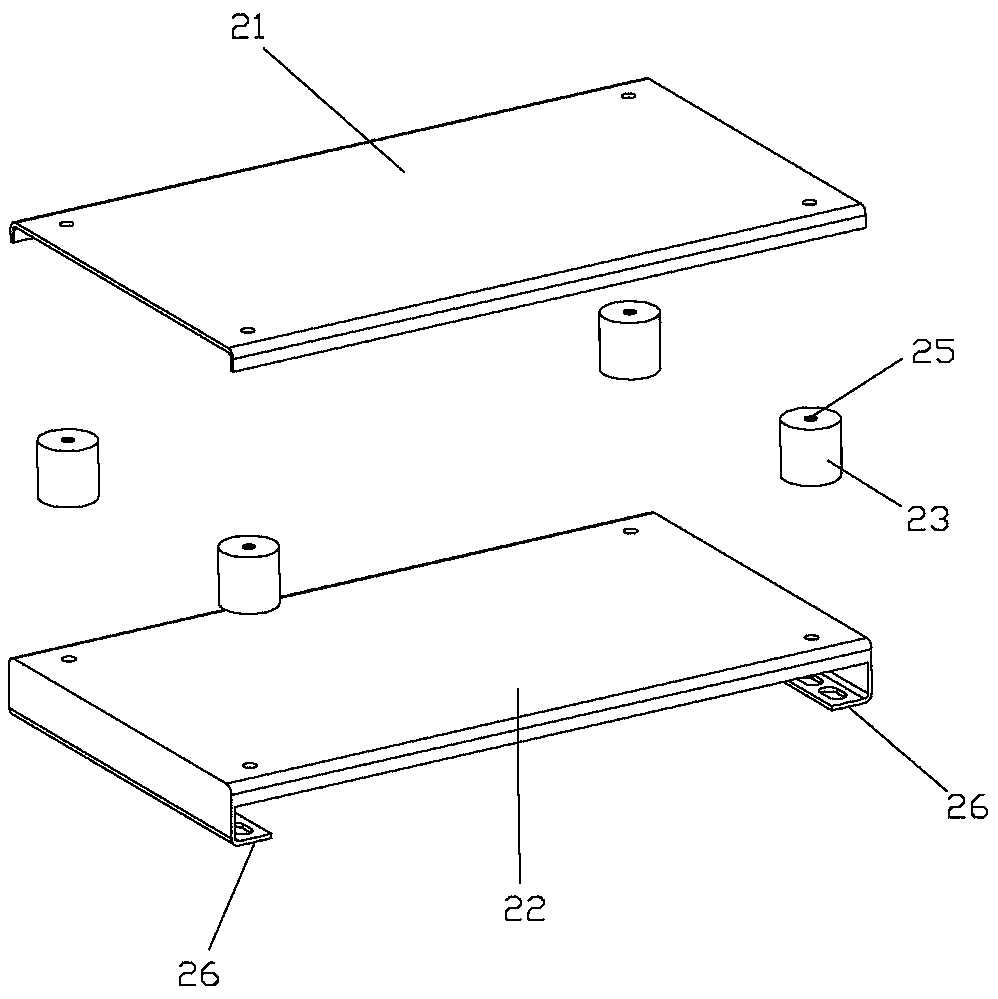

[0025] The base 2 includes an upper plate 21, a bottom plate 22 and a damping column 23, the upper plate 21 and the base plate 22 are parallel to each other, and are connected by a number of damping columns 23. The describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com