Method for drilling coal-bed gas well penetrating through goaf by means of composite blocking of hole-bottom broken rock masses

A technology for coalbed methane wells and goafs, which is applied in drilling equipment and methods, drilling equipment, wellbore/well components, etc., can solve problems such as drilling difficulties, hidden dangers, and drilling existence, and achieve simplified grouting equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

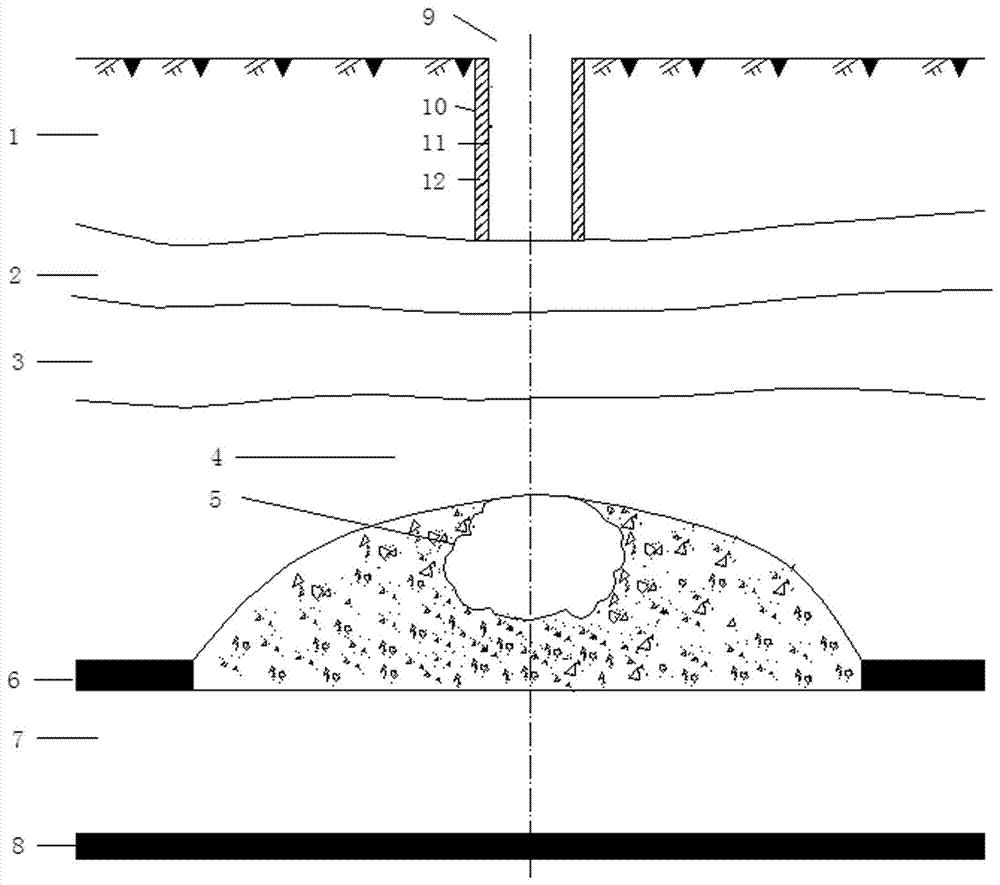

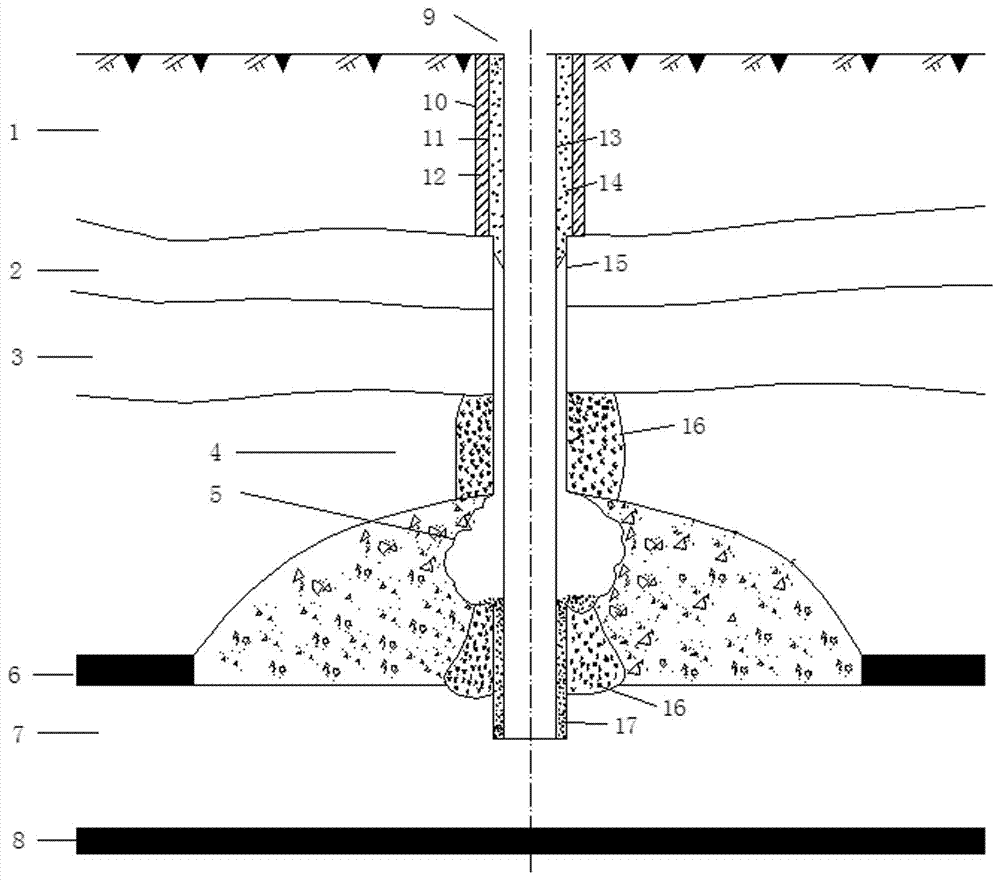

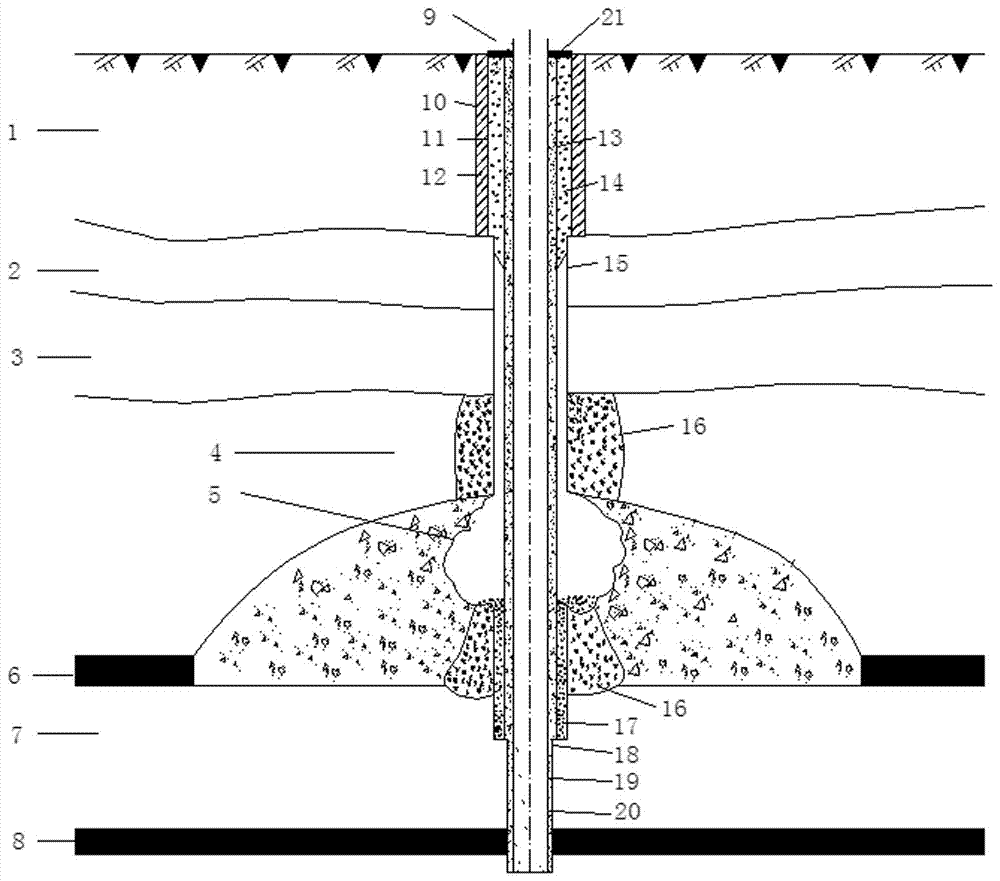

[0042] Aiming at the unfavorable geological conditions of coalbed methane well drilling with a large number of broken rock masses or cavities in the goaf, the present invention is based on the pneumatic down-the-hole hammer drilling method, combined with injection of foam liquid at the bottom of the hole, grouting at the bottom of the key broken rock mass, and casing Auxiliary technologies such as follow-up and technical casing end grouting stabilization have solved the drilling technical problems that it is difficult for coalbed methane wells to penetrate the broken rock mass or hollow section of the goaf. The key point of the technique is that the coalbed methane wells are drilled in stages with three opening diameters in sequence, and the second drilling stage passes through the goaf. Among them, in the moderately broken rock mass section (middle and upper part of the fissure zone), the auxiliary measures of injecting foam liquid at the bottom of the hole are implemented; in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com