Inertia damping device for attached plate type viscosity unit

A shock-absorbing device and viscous technology, which is applied in the direction of earthquake-proof, protective buildings/shelters, building components, etc., can solve problems such as insufficient energy consumption, and achieve the effects of small installation mass, reduced response, and effective vibration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

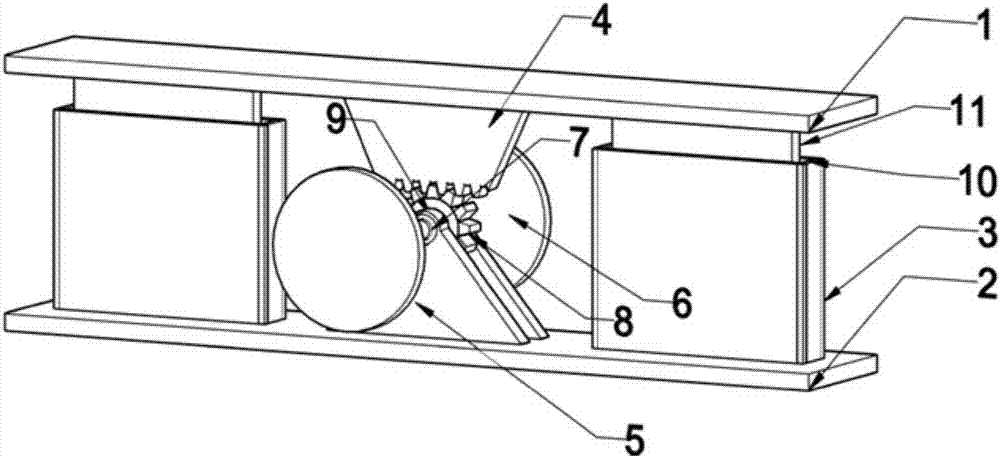

[0019] Such as figure 1 shown.

[0020] The device of the present invention comprises a plate type viscous energy consumption unit, an upper connection plate (1) and a lower connection plate (2), and the plate type viscous energy consumption unit is fixed to the structural wall through the upper connection plate (1) and the lower connection plate (2) The body is characterized in that a gear-type inertial unit (as an embodiment) is also designed as a synergistic mechanism of the plate-type viscous energy dissipation unit.

[0021] The plate-type viscous energy consumption unit is composed of an outer steel plate (3), an inner steel plate (11) and a high-viscosity liquid (10), the high-viscosity liquid 10 is placed in the closed body of the outer steel plate (3), and the inner steel plate (11) ) into the high viscosity liquid (10). The inner steel plate and the outer steel plate are respectively consolidated with the upper and lower connecting plates as a whole. Specifically,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com