Elastic floor mat for artificial turf and preparation method thereof

An artificial turf and elastic floor technology, applied in the directions of roads, buildings, pavements, etc., can solve the problems of weak pulling force of floor mats, inability to meet large water displacement, etc., and achieve the effects of strong compression resistance, low compounding efficiency, and environmental protection of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

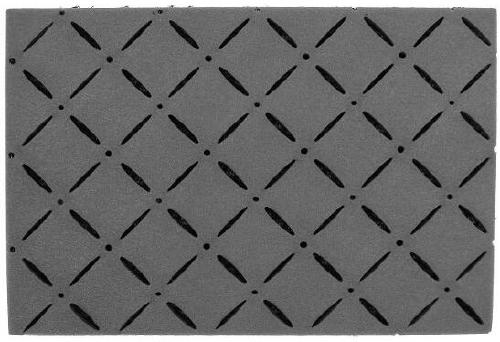

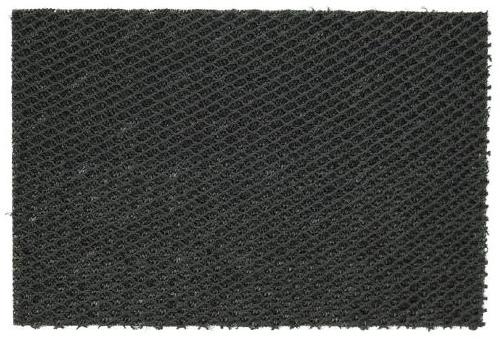

[0032] Such as Figure 1-2 The elastic floor mat shown is composed of a plane elastic body and multiple groups of permeable structures designed on the plane elastic body. One side of the elastic body is attached with 3D mesh cloth.

[0033] Among them, the 3D mesh fabric is made of PA nylon with a thickness of 5mm. The mesh fabric is made of single-filament double-sided weaving technology. The side with high density is close to the flat elastic body. The diameter of the thread is 0.2mm. DTEX5000, 4 layers of weaving, the preparation process of elastic floor mats Specifically: the elastic body and the 3D mesh cloth are combined with glue.

Embodiment 2

[0035] Example 2 adopts the same planar elastic body as in Example 1. The 3D mesh cloth is made of PA nylon with a thickness of 5 mm. The mesh cloth is made by a single-filament double-sided weaving process. The side with a high density of threads is close to the planar elastic body, and the diameter of the thread is 0.2 mm. DTEX5000, braided 4 layers.

[0036] The preparation process of the elastic floor mat is as follows: the elastic body and the 3D mesh cloth are compounded by hot melting, and the elastic body and the 3D mesh cloth are brought into an initial melting state at 160-270 ° C, and then the elastic body and the 3D mesh cloth are rapidly melted. (within 1-3 seconds) hot pressing compound.

Embodiment 3

[0038] Example 3 uses the same planar elastic body as in Example 1, and a channel is added on the side where the planar elastic body is combined with the 3D mesh cloth. The specific channel design can refer to the specific description in patent 201620390590.8. In this example, the 3D mesh cloth is made of polypropylene fiber with a thickness of 5mm. The mesh cloth is made by single-filament double-sided weaving process. The side with high thread density is close to the flat elastic body. The thread diameter is 0.2mm, DTEX5000, and 4 layers of weaving.

[0039] The preparation process of the elastic floor mat is as follows: the elastic body and the 3D mesh cloth are compounded by hot melting, and the elastic body and the 3D mesh cloth are brought into an initial melting state at 160-270 ° C, and then the elastic body and the 3D mesh cloth are rapidly melted. (within 1-3 seconds) hot pressing compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com