Synthesis method of benzothiazole-nitrogen-containing heterocyclic ring hybrid

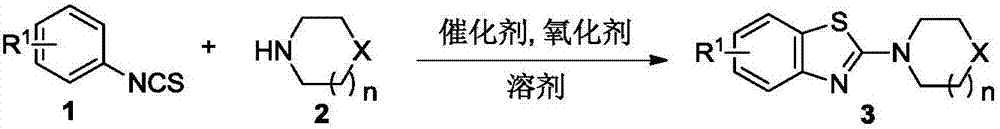

The technology of a benzothiazole and a synthesis method is applied in the field of synthesis of benzothiazole-nitrogen-containing heterocyclic hybrids, and can solve the problems of low product yield and atom economy, limited preparation methods, and difficulty in obtaining raw materials, and the like, Achieve the effect of cheap raw materials, simple operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]

[0023] Add 1a (0.55mmol, 66μL), 2a (0.5mmol, 44μL), chlorobenzene (3mL) and iodine (0.25mmol, 63.5mg) to a 10mL Shrek tube in sequence, and place it at 120 ℃ oil bath stirring reaction for 14h. Then, 10 mL of saturated sodium thiosulfate solution was added to quench the reaction, extracted with ethyl acetate (10 mL×3), the combined organic phases were washed with distilled water and saturated brine successively, the resulting organic phase was dried over anhydrous sodium sulfate, filtered, After spin-drying, silica gel column separation (petroleum ether / ethyl acetate=10 / 1) gave the product 3a (69.4 mg, 63%) as a white solid. The characterization data of this compound are as follows: 1 HNMR (400MHz, CDCl 3 )δ: 3.62(t, J=4.8Hz, 4H), 3.83(t, J=4.8Hz, 4H), 7.10(t, J=7.6Hz, 1H), 7.31(t, J=8.0Hz, 1H) ,7.56-7.62(m,2H). 13 C NMR (100MHz, CDCl 3 )δ: 48.5, 66.3, 119.4, 120.8, 121.7, 126.1, 130.6, 152.5, 169.0. MS: m / z 221 [M+H] + .

Embodiment 2

[0025] Add 1a (0.55mmol, 66μL), 2a (0.5mmol, 44μL), toluene (3mL) and iodine (0.25mmol, 63.5mg) to a 10mL Shrek tube in turn, and place it at 120°C after vacuumizing and filling with oxygen The reaction was stirred in an oil bath for 14h. Then, 10 mL of saturated sodium thiosulfate solution was added to quench the reaction, extracted with ethyl acetate (10 mL×3), the combined organic phases were washed with distilled water and saturated brine successively, the resulting organic phase was dried over anhydrous sodium sulfate, filtered, After spin-drying, silica gel column separation (petroleum ether / ethyl acetate=10 / 1) gave the product 3a (38.6 mg, 35%) as a white solid.

Embodiment 3

[0027] Add 1a (0.55mmol, 66μL), 2a (0.5mmol, 44μL), dimethyl sulfoxide (3mL) and iodine element (0.25mmol, 63.5mg) to a 10mL Shrek tube in turn, vacuumize and fill it with oxygen Placed in an oil bath at 120°C and stirred for 14 hours. Then, 10 mL of saturated sodium thiosulfate solution was added to quench the reaction, extracted with ethyl acetate (10 mL×3), the combined organic phases were washed with distilled water and saturated brine successively, the resulting organic phase was dried over anhydrous sodium sulfate, filtered, After spin-drying, silica gel column separation (petroleum ether / ethyl acetate=10 / 1) gave the product 3a (24.2 mg, 22%) as a white solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com