Antisludging agent used for disposing sewage with supercritical water oxidation technology and application of antisludging agent

A technology of supercritical water oxidation and technical treatment, which is applied in the direction of oxidation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Equipment oxidation efficiency and other issues to achieve the effect of reducing fouling, reducing deposition, and promoting oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The total hardness is 500mg / L (calculated as calcium, 12.5mol / t), the raw water alkalinity is 0.01mol / t, after configuration, it needs to be maintained at 0.05mol / t, and the wastewater COD concentration is 20000mg / L. Therefore, every ton of wastewater treated requires Add 5% by mass of sodium carbonate and sodium nitrite (mass ratio 10:0.2) 13.292 kg of scale inhibitor solution, the concentration of salicylic acid in the scale inhibitor solution is 2%;

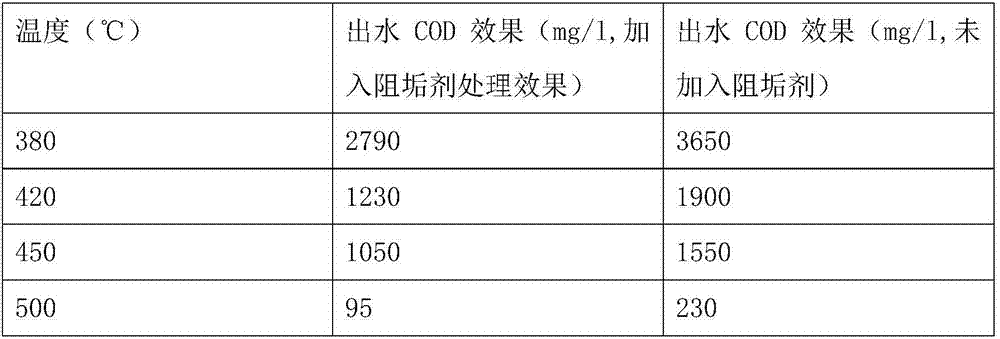

[0029] Using the supercritical pilot plant to treat the waste water described in Application Case 1, under the same experimental conditions, experiments with and without scale inhibitors were carried out. The experimental data are shown in Table 1.

[0030] Table 1: Comparison of the effects of adding antiscalants in supercritical experiments (running at 25MPa; sodium carbonate, sodium nitrite (10:0.2), salicylic acid (2% concentration))

[0031]

[0032]

Embodiment 2

[0034] The total hardness is 3000mg / L (calculated as calcium, 75mol / t), the raw water alkalinity is 0.02mol / t, and it needs to be maintained at 0.05mol / t after configuration; the wastewater COD concentration is 100000mg / L in wastewater, so it is necessary to treat each ton of wastewater Add 10% by mass of sodium carbonate and sodium nitrite (mass ratio 10:1) 39.766kg of scale inhibitor solution, 5-nitro-2-hydroxybenzoic acid and sodium acetate (mass ratio 1:1) in the scale inhibitor solution 1) the concentration is 9%;

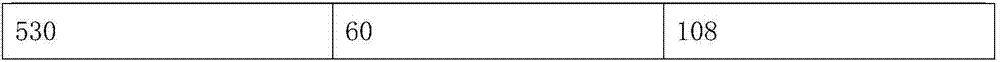

[0035] Using the supercritical pilot plant to treat the waste water described in Application Case 2, under the same experimental conditions, experiments with and without scale inhibitors were carried out. The experimental data are shown in Table 2.

[0036] Table 2: Comparison of the effects of adding antiscalants in supercritical experiments (running at 25MPa; sodium carbonate, sodium nitrite (10:1), 5-nitro-2-hydroxybenzoic acid and sodium acetate (9% concen...

Embodiment 3

[0039] The total hardness is 800mg / L (calculated as magnesium, 33.33mol / t), the raw water alkalinity is 0.0mol / t, and it needs to be maintained at 0.05mol / t after configuration; the wastewater COD concentration of wastewater is 80000mg / L, and the mass of wastewater added per ton The antiscalant solution of sodium carbonate and sodium nitrite (mass ratio 10:0.5) 29.489kg of percentage 6%, dinitrosalicylic acid, pyruvic acid and sodium edetate (three Mass ratio 1:1:0.5) concentration is 8%.

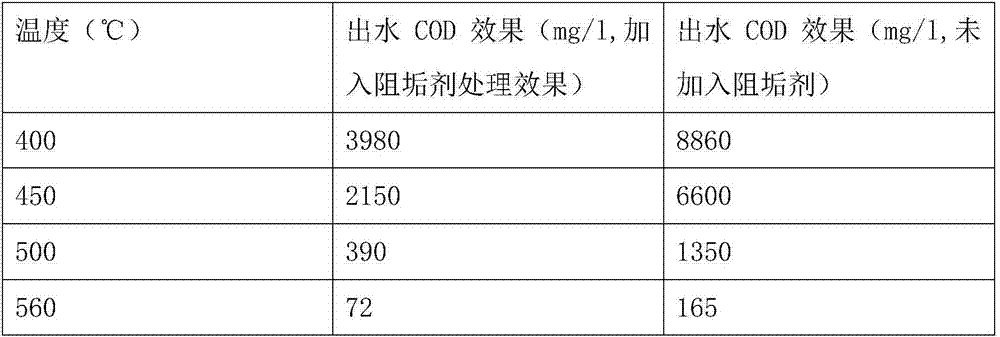

[0040] Using the supercritical pilot plant to treat the waste water described in Application Case 3, under the same experimental conditions, the experiments with and without scale inhibitors were carried out. The experimental data are shown in Table 3.

[0041] Table 3: Comparison of the effects of adding scale inhibitors to supercritical experiments (operating under the condition of 25MPa; sodium carbonate, sodium nitrite (10:0.5), dinitrosalicylic acid, pyruvic acid and sodium edetate (8%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com