An open pallet stacking and dismantling device

An open pallet technology, applied in the direction of unstacking of objects, stacking of objects, transportation and packaging, etc., can solve the problems that cannot be realized simultaneously, reduce labor force, reduce labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

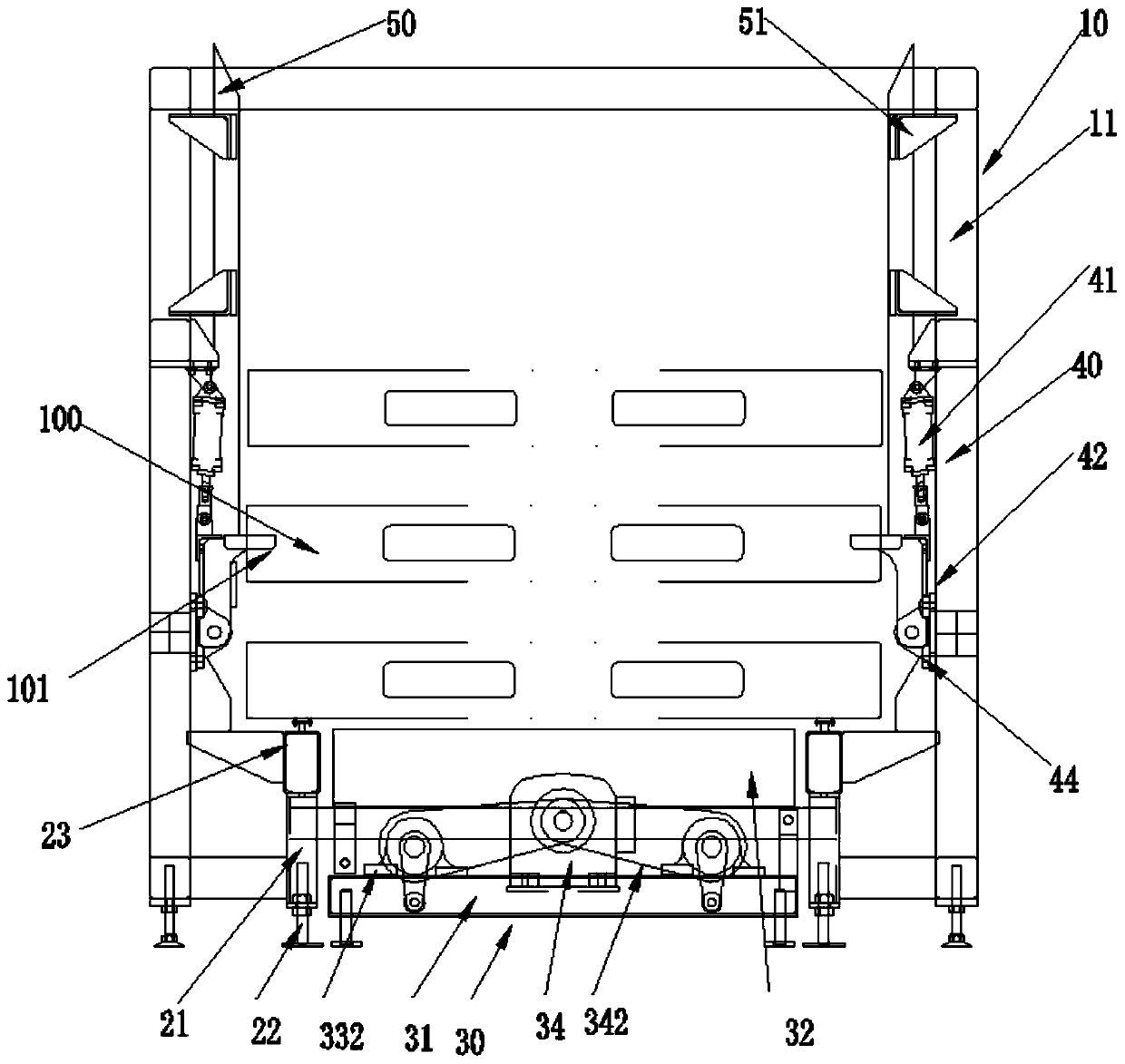

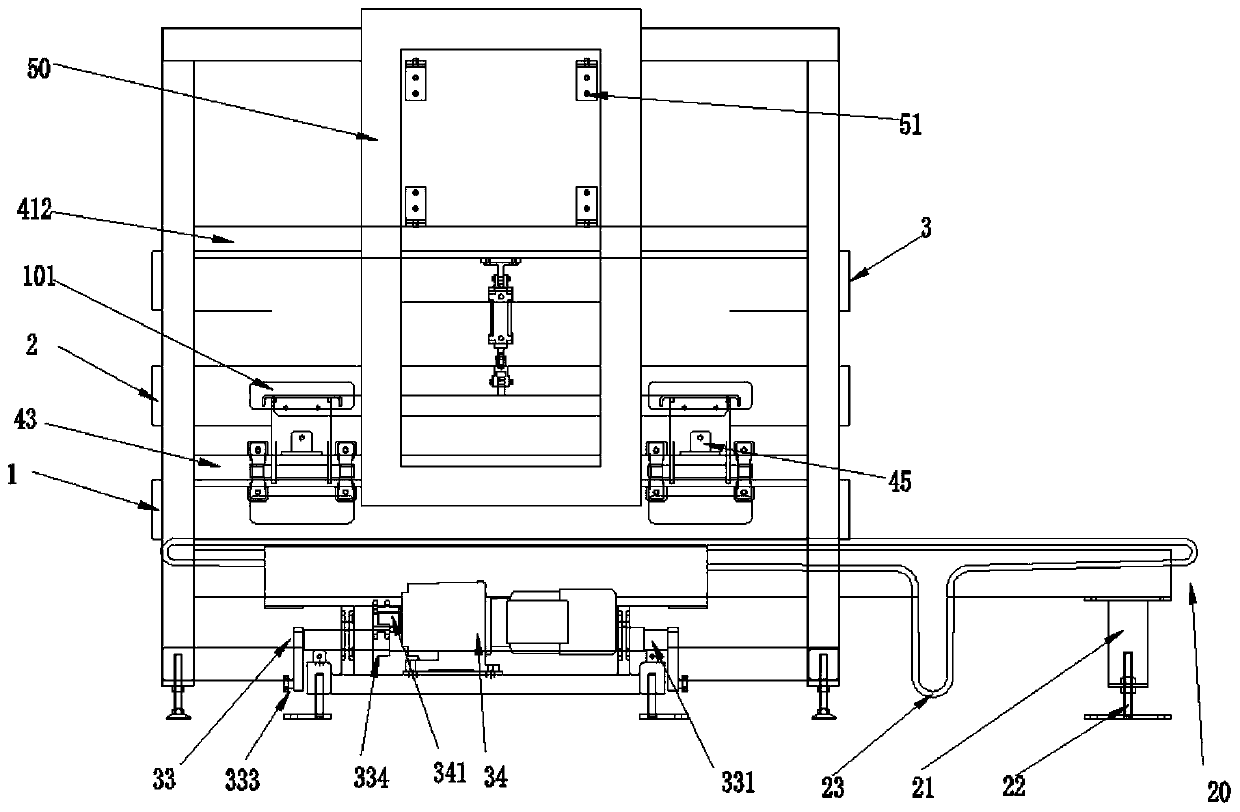

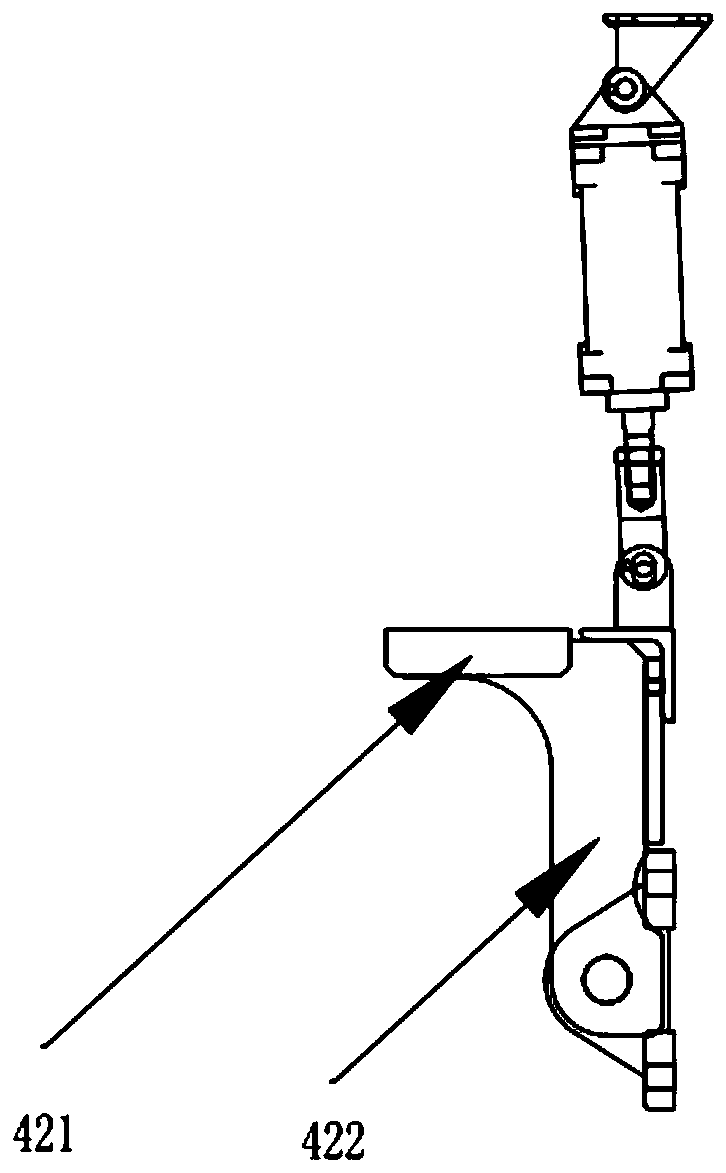

[0021] combine Figure 1 to Figure 4 The shown open pallet stacking and dismantling device, in this embodiment, includes a frame 10 and a conveying device 20 passing through the inside of the frame 10, and also includes a shifting mechanism 40 located on both sides of the frame 10 and a The jacking mechanism 30 in the middle of the conveying device 20 also includes a rectangular guide plate 50 located on both sides of the frame 10 and a guide bracket 51 fixing the rectangular guide plate 50 to the column 11, so as to realize the micro-guidance of the pallet. , to prevent falling pallets, the frame 10 includes four columns 11 arranged in a rectangle; the shifting block mechanism 40 includes a cylinder assembly 41 fixed on one side of the frame 10, a shifting block 42 connected to the cylinder assembly 41 at one end, and a block 42 fixed on the column The connecting bearing fixed frame 43 on 11 and the connecting bearing 44 fixed on the connecting bearing fixing frame 43, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com