Self-adjusted scraper plate type backwash filter for ocean nuclear power platform

A self-adjusting, nuclear power technology, applied in the direction of fixed filter elements, filtration and separation, chemical instruments and methods, etc., can solve the problems of reducing flow performance, affecting lubrication effect, clogging marine organisms, etc., to prolong service life and shrink Headroom, avoiding excessive wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

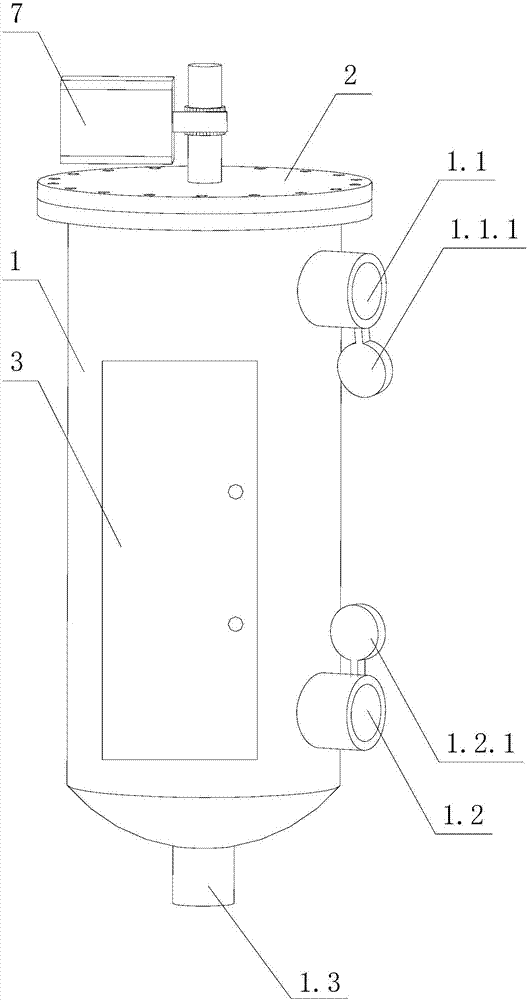

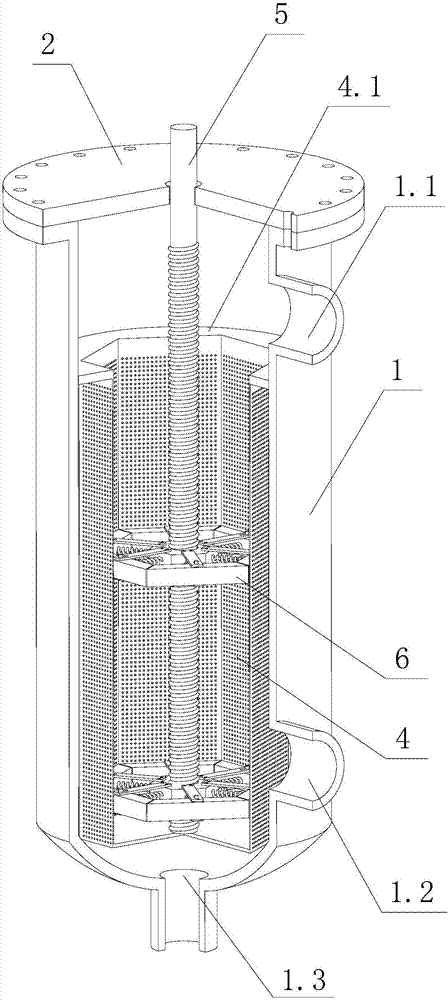

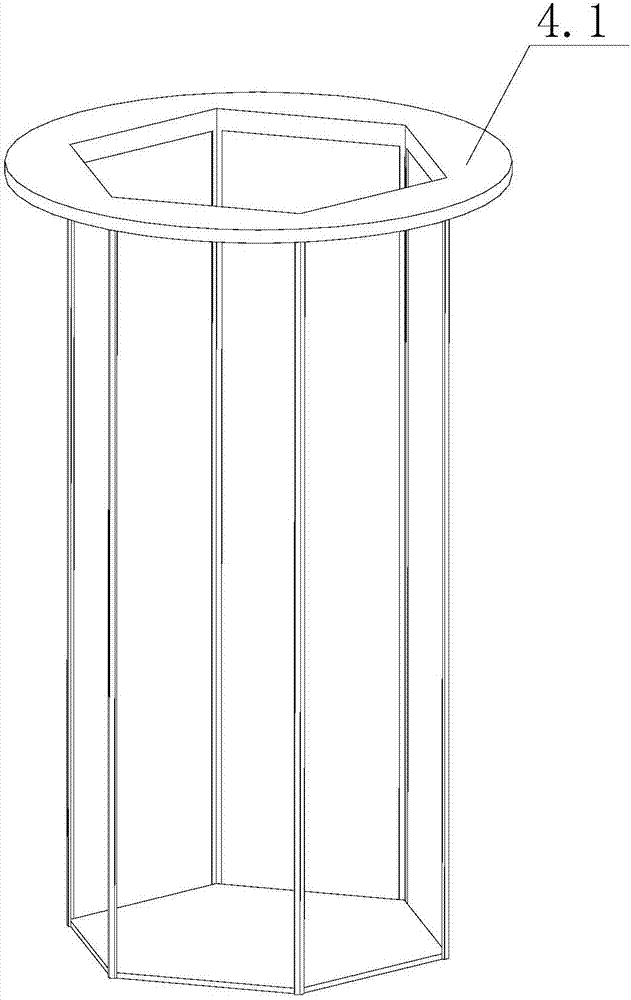

[0020] As shown in the figure, the self-adjusting scraper type backwash filter for marine nuclear power platforms includes a cylinder body 1 and an upper cover 2 matched with the top of the cylinder body 1. The upper, lower and bottom parts of the cylinder body 1 are respectively provided with output ports. 1.1, the input port 1.2 and the sewage outlet 1.3, the cylinder 1 is provided with a maintenance door 3, the cylinder 1 is provided with a rotatable filter frame 4.1, and the periphery of the filter frame 4.1 is connected with a detachable filter plate 4.2, The filter screen plate 4.2 and the filter screen frame 4.1 form a prismatic filter screen 4 together. The cylinder body 1 is provided with a threaded rod 5 arranged coaxially with the cylinder body 1 and rotatable aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com