A quick way to get rid of bitterness and astringency in Lanqian

A technology of removing bitterness and bitterness of lavender, which is applied in the direction of food ingredients as taste improvers, food science, food ingredients, etc., can solve the problem that the effect of removing bitterness and astringency is not ideal, restricts the development of deep-processed products of lavender, and consumes a lot of time And resources and other issues, to achieve the effect of shortening the time for removing bitterness and astringency, completely removing bitterness and astringency, and good sensory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

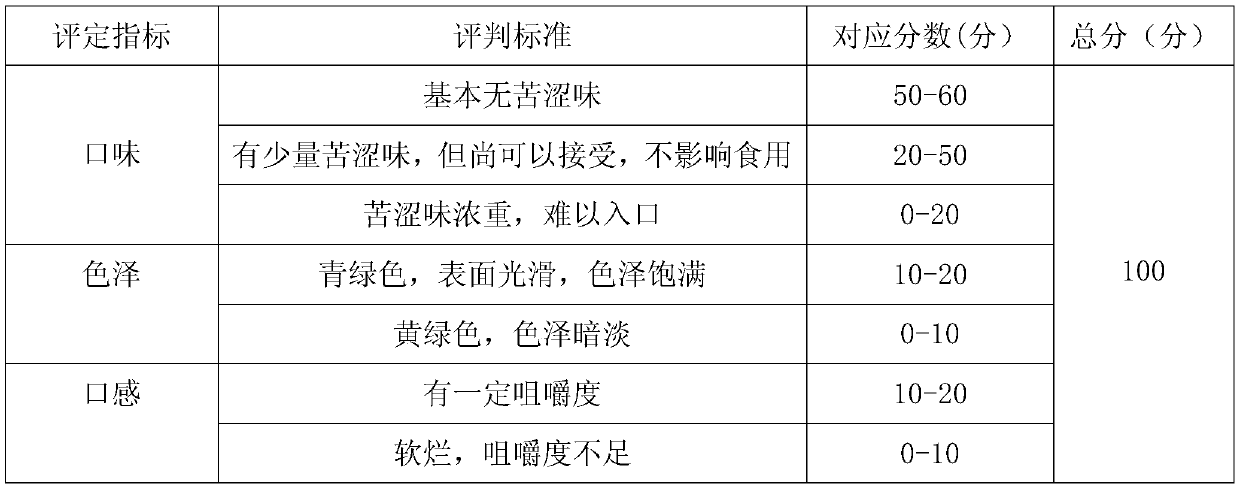

Image

Examples

Embodiment 1

[0024] A method for quickly removing the bitterness and astringency of Lanqian, comprising the following steps:

[0025] (1) Washing and peeling: select mature and complete Lavender, rinse with water, boil in a water bath at a temperature of 95°C for 5 minutes, remove and cool down, peel the cooled Lavender, and set aside;

[0026] (2) Ultrasonic treatment: according to the mass ratio of 1:2, put the peeled Lamia in step (1) into a sodium carbonate solution with a pH of 10.7 to obtain the first mixture, and place the first mixture in ultrasonic treatment In the device, after processing for 1.5h at an ultrasonic power of 500W and a temperature of 25°C, it is ready for use;

[0027] (3) Gradient lye vacuum tumbling treatment:

[0028] S1: Put the first mixture in step (2) into a vacuum tumbler, tumble and knead for 2 hours under a vacuum of 0.07MPa, take it out, and set aside;

[0029] S2: After diluting the sodium carbonate solution in the first mixture that has been tumbled ...

Embodiment 2

[0033] A method for quickly removing the bitterness and astringency of Lanqian, comprising the following steps:

[0034] (1) Washing and peeling: select mature and complete lavender, rinse with water, put it in a water bath with a temperature of 98°C and boil for 4 minutes, remove and cool down, peel the cooled lavender, and set aside;

[0035] (2) Ultrasonic treatment: according to the mass ratio of 2:3, putting the peeled Lamara in step (1) into a sodium carbonate solution with a pH of 11.0 to obtain the first mixture, and placing the first mixture in ultrasonic treatment In the device, after processing for 1.0h at an ultrasonic power of 600W and a temperature of 30°C, it is ready for use;

[0036] (3) Gradient lye vacuum tumbling treatment:

[0037] S1: Put the first mixture in step (2) into a vacuum tumbler, tumble and knead for 1.5 hours under a vacuum of 0.08MPa, take it out, and set aside;

[0038] S2: After diluting the sodium carbonate solution in the first mixture ...

Embodiment 3

[0042] A method for quickly removing the bitterness and astringency of Lanqian, comprising the following steps:

[0043] (1) Washing and peeling: select mature and complete lavender, rinse with water, boil in a water bath at 100°C for 3-5 minutes, remove and cool down, peel the cooled lavender, and set aside;

[0044] (2) Ultrasonic treatment: according to the mass ratio of 3:5, putting the peeled Lamia in step (1) into a sodium carbonate solution with a pH of 11.3 to obtain the first mixture, and placing the first mixture in ultrasonic treatment In the device, after processing for 0.5h at an ultrasonic power of 700W and a temperature of 35°C, it is ready for use;

[0045] (3) Gradient lye vacuum tumbling treatment:

[0046] S1: Put the first mixture in step (2) into a vacuum tumbler, tumble and knead for 1 hour under a vacuum of 0.09MPa, and then take it out for use;

[0047] S2: Dilute the sodium carbonate solution in the first mixture that has been tumbled in S1 to a pH o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com