Noise reduction crusher

A crusher and noise reduction technology, applied in the direction of grain processing, etc., can solve the problems of unsatisfactory working environment of production personnel, physical damage of production personnel, inconvenient crushing work, etc., to achieve good crushing effect, improve production environment, and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

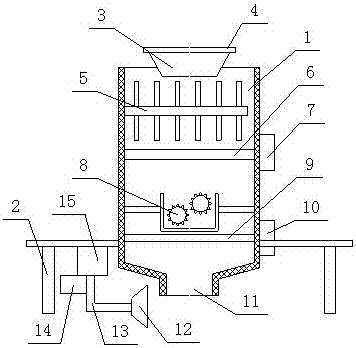

[0010] Example: such as figure 1 As shown, a noise reduction crusher includes a crushing barrel 1 and a support frame 2, the crushing barrel 1 is located on the support frame 2, and the top of the crushing barrel 1 is provided with a feed port 3, and the feed port 3 is provided with a matching The upper part of the crushing bucket 1 is provided with a primary crushing device 5, and the bottom of the primary crushing device 5 is provided with a vibrating sieve plate 6. The vibrating sieve plate 6 is located in the middle of the crushing bucket 1. One end of the vibrating sieve plate 6 It is connected with a vibration driving device 7, and the vibration driving device 7 is located on the outer wall of the crushing barrel 1. The inner bottom of the crushing barrel 1 is provided with a secondary crushing device 8, and the bottom of the secondary crushing device 8 is provided with a swinging sieve plate 9, and the swinging sieve plate One end of 9 is connected with a swing driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com