Method for measuring ammonium ion content of coal ash

A determination method and fly ash technology, applied in the field of ammonia desulfurization, can solve problems such as inability to detect, and achieve the effects of short time consumption, simple operation and small experimental error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

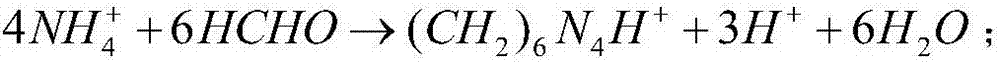

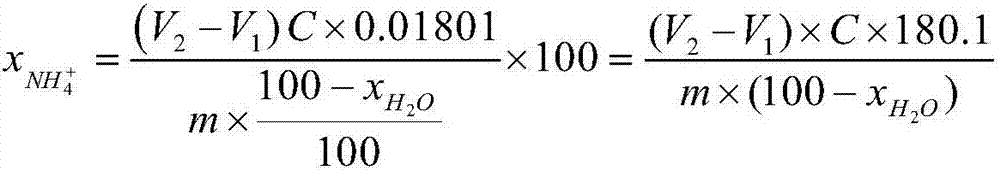

Method used

Image

Examples

Embodiment 1

[0074] The sample of embodiment 1 is to mix analytically pure ammonium sulfite in the common fly ash sample not containing ammonium root ion, make its ammonium root ion [NH 4 + ] content is 3.0%; The sample of embodiment 2 is to mix analytically pure ammonium bisulfite in the common fly ash sample that does not contain ammonium root ion, makes its ammonium root ion [NH 4 + ] content is 4.0%; The sample of embodiment 3 is that the analytical pure ammonium sulfite and ammonium bisulfite that respectively account for 50% are mixed in the common fly ash sample that does not contain ammonium root ion, make its ammonium root ion [NH 4 + ] The total content is 5.0%.

[0075] Example 1

[0076] Weigh 1.0g of fly ash sample containing analytically pure ammonium sulfite, accurate to 0.1mg, put it in a 250mL beaker, add 70-80mL of distilled water, cover with a watch glass, place the beaker on a magnetic stirrer and stir for 10min, After stirring, wash the watch glass and the cup wal...

Embodiment 2

[0078] Weigh 1.0g of fly ash sample containing analytically pure ammonium bisulfite, accurate to 0.1mg, put it in a 250mL beaker, add 70-80mL of distilled water, cover with a watch glass, place the beaker on a magnetic stirrer and stir for 10min , after stirring, rinse the watch glass and cup wall with a small amount of distilled water, and let it stand for 5 minutes; filter with medium-speed quantitative filter paper, collect the filtrate and lotion in a 250mL conical flask, and control the volume of the lotion within 50mL as much as possible; Add 2 drops of 1g / L methyl red indicator solution to the shaped bottle solution, add dropwise 0.1mol / L hydrochloric acid solution to adjust the solution to orange; add 15mL 250g / L formaldehyde solution to the test solution, and then add 3 drops of 10g / L phenolphthalein indicator solution, shake well, after standing for 5min, titrate slowly with 0.15mol / L sodium hydroxide standard titration solution to light red, which does not disappear ...

Embodiment 3

[0080] Weigh 1.0g of fly ash sample containing analytically pure ammonium sulfite and ammonium bisulfite, accurate to 0.1mg, put it in a 250mL beaker, add 70-80mL of distilled water, cover with a watch glass, and place the beaker under magnetic stirring Stir on the mixer for 10 minutes. After the stirring, rinse the watch glass and cup wall with a small amount of distilled water, and let it stand for 5 minutes; filter with medium-speed quantitative filter paper, collect the filtrate and lotion in a 250mL conical flask, and control the volume of the lotion at 50mL as much as possible. Within; add 2 drops of 1g / L methyl red indicator solution to the Erlenmeyer flask solution, add dropwise 0.1mol / L hydrochloric acid solution to adjust the solution to orange; add 15mL 250g / L formaldehyde solution to the test solution, and then add 3 drops of 10g / L phenolphthalein indicator solution, shake well, after standing for 5min, slowly titrate with 0.15mol / L sodium hydroxide standard titrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com