Impact testing device for debris flow protection structure

A protective structure and impact test technology, which is applied in the testing of machines/structural components, measuring devices, impact tests, etc., can solve the problem that the test device that does not simulate the impact of debris flow, the impact force and the impact process cannot accurately simulate the protective structure Problems such as continuous impact effect, to achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

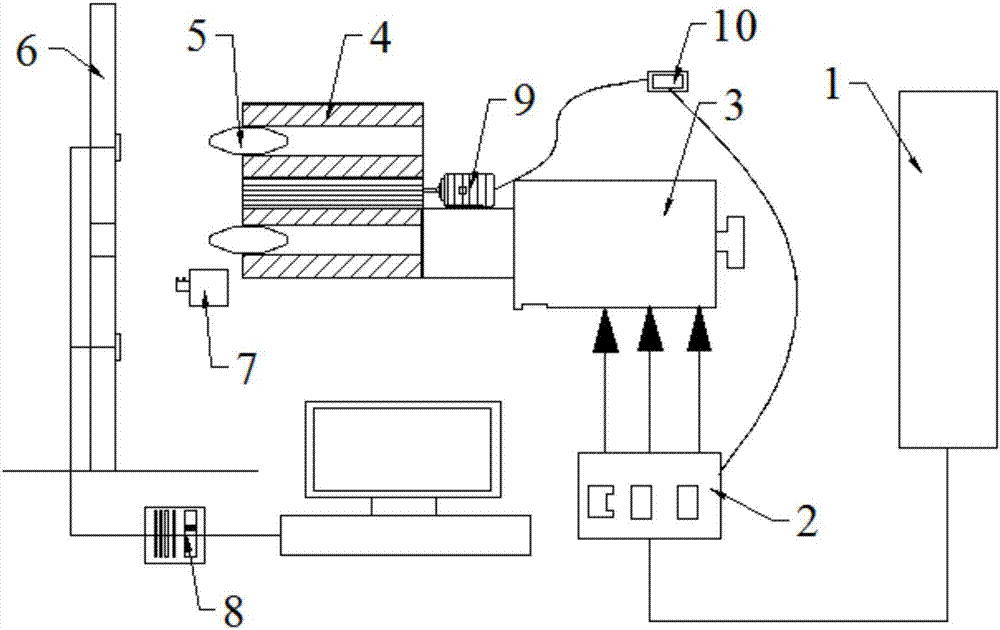

[0020] Such as figure 1 The debris flow protective structure impact test device shown includes a cylinder 1, a launching device 3, a runner 4, a conical impact bullet 5, a high-speed camera 7 and an experimental protective structure 6;

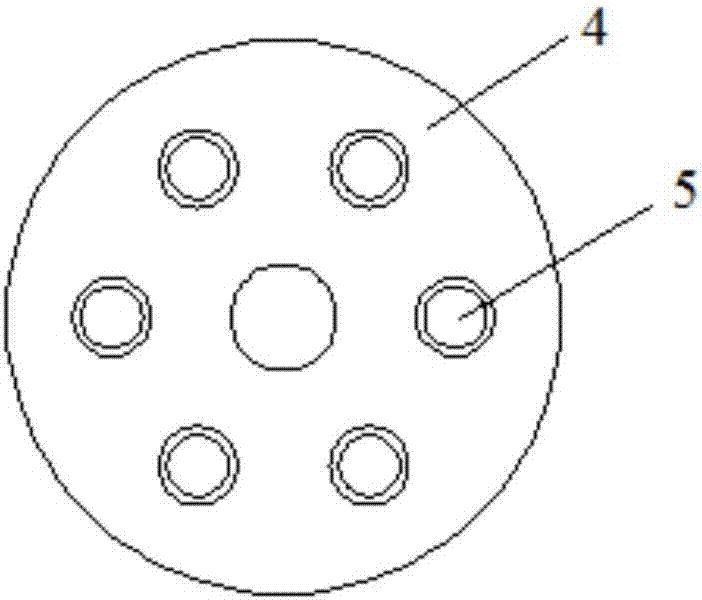

[0021] Cylinder 1 is connected with launcher 3, and launcher 3 is provided with control switch 2 to control the size of impact force; Launcher is connected with cylindrical runner 4, such as figure 2 As shown, the runner 4 has six chambers, and the chambers are respectively equipped with conical impact bullets 5;

[0022] The speed regulating motor 9 is connected with the rotating shaft of the runner 4, and the speed regulating motor 9 and the control switch 2 are respectively connected with the launch speed controller 10;

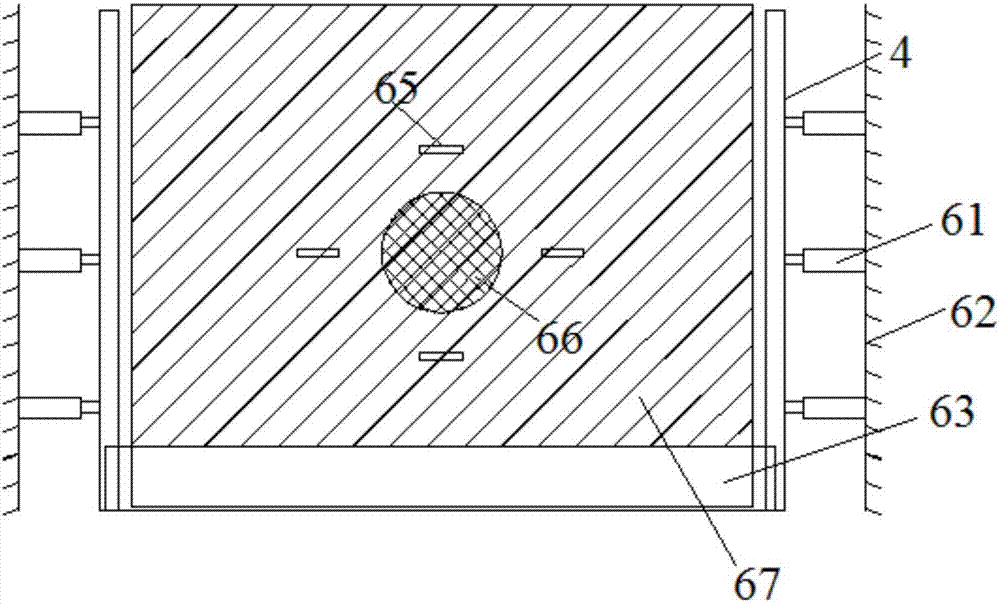

[0023] An experimental protective structure 6 is installed in front of the launch of the runner 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com