Curvature-adaptive pulley block

A self-adaptive, pulley block technology, applied in hoisting devices, portable hoisting devices, etc., can solve the problems of damage to the internal structure of the rope, excessive bending of the rope, and high production costs, reducing bending, improving bending, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The following is a description of Embodiment 1.

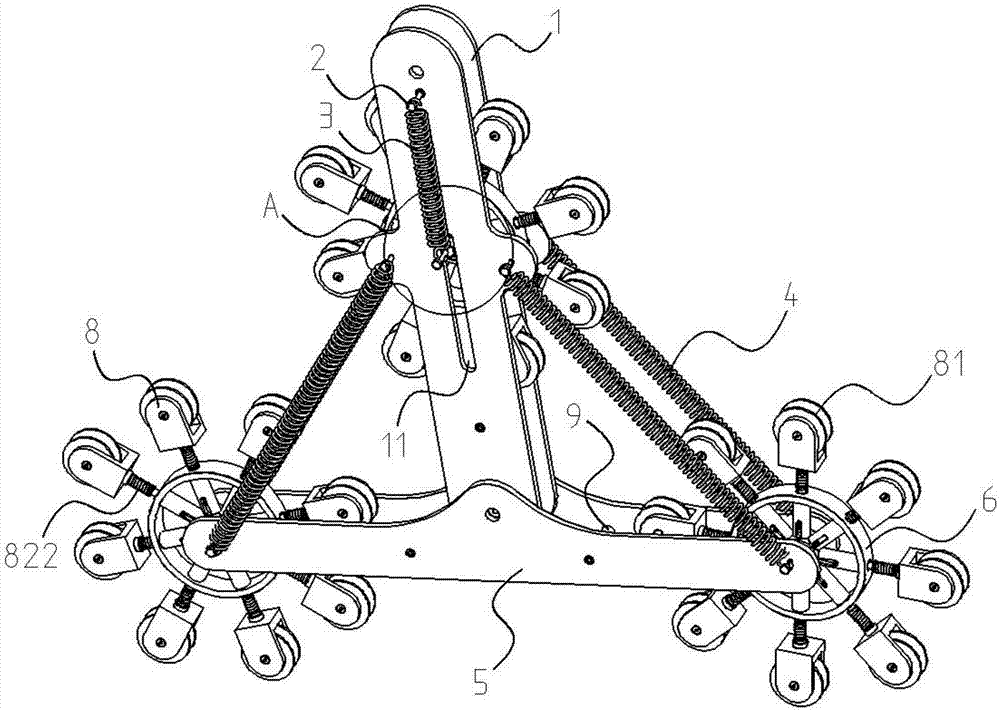

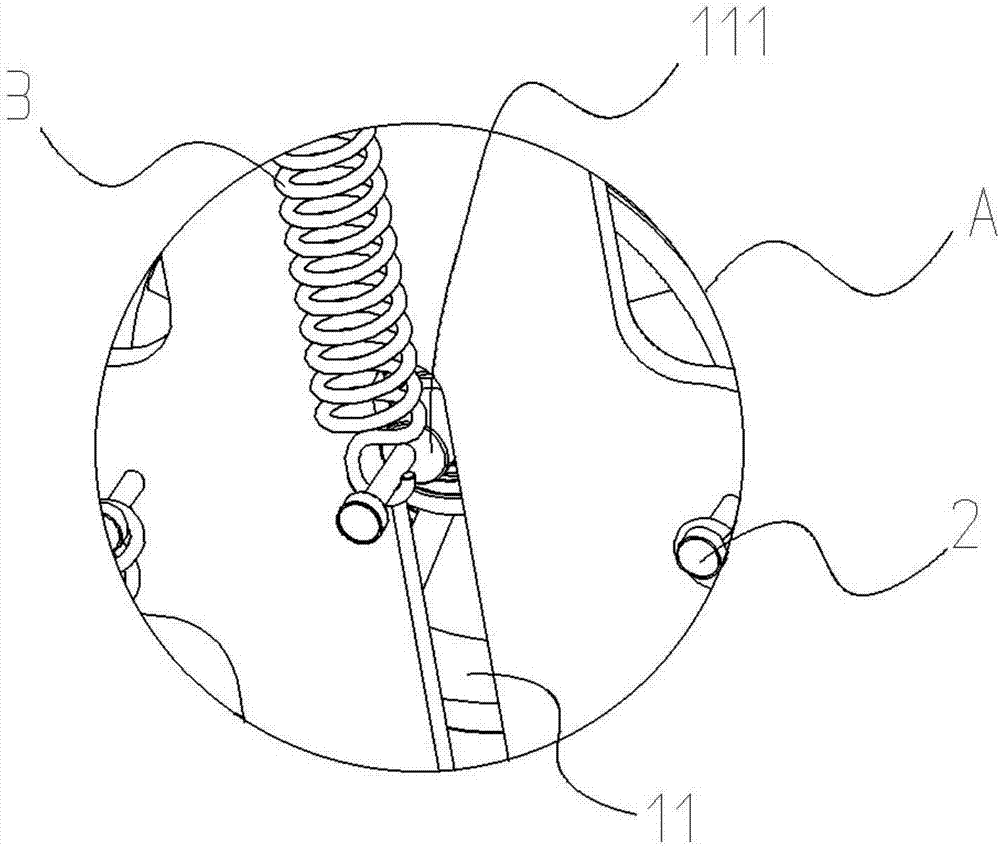

[0030] Such as Figure 1 to Figure 7 As shown, a curvature adaptive pulley block includes a vertical main suspension plate 1, a positioning track groove 11, a positioning sliding column 111, a tension spring fixing column 2, an upper tension spring 3, a return tension spring 4, and a lateral support end plate 5. Wheel-shaped installation body 6, bearing 7, pulley mounting seat 8, pulley 81, support rod 82, support sliding column 821, spring 822, reinforcement fixing rod 9, the vertical main suspension plate 1 and the lateral support end plate 5 are respectively provided with two pieces, two vertical main suspension plates 1 are opposite to two horizontal support end plates 5 and are connected and fixed through the reinforcing fixing rod 9 arranged in the middle, the bottom of the vertical main suspension plate 1 is connected with the horizontal support end plate 5 The middle positions of the support end plates 5 are axi...

Embodiment 2

[0035] The following is the description of the second embodiment.

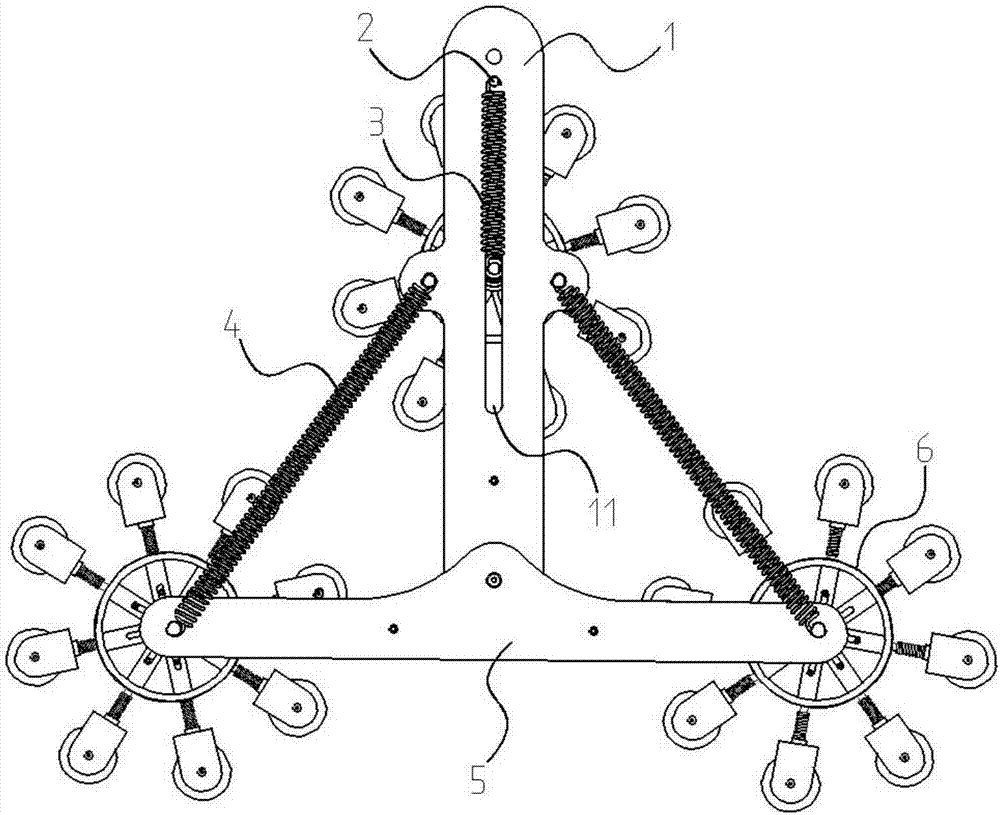

[0036] In embodiment 2, for the same structure as in embodiment 1, the same labels are given, and the same description is omitted. The middle position of the vertical main suspension plate 1 and the lateral support end plate 5 is fixedly connected by a shaft connection, Omitting the two return springs 4 installed between the vertical main suspension plate 1 and the lateral support end plate 5 through the tension spring fixing column 2 reduces the production cost and at the same time achieves the effect of reducing the bending fatigue damage of the rope.

[0037] When this device is installed, after fixing the top of the vertical main suspension plate 1, the ropes are installed on the pulleys 81 provided outside the three wheel-shaped installation bodies 6, and the strengthening fixing rod 9 can be used for the vertical main suspension plate 1 and the horizontal direction. The support end plate 5 is effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com