Asymmetrical excitation stator alternate-angle dual-salient-pole motor and control method thereof

A technology of doubly salient motor and excitation stator, which is applied in the direction of controlling mechanical energy, magnetic circuit, electromechanical device, etc., and can solve problems such as motor pulsation and small phase torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

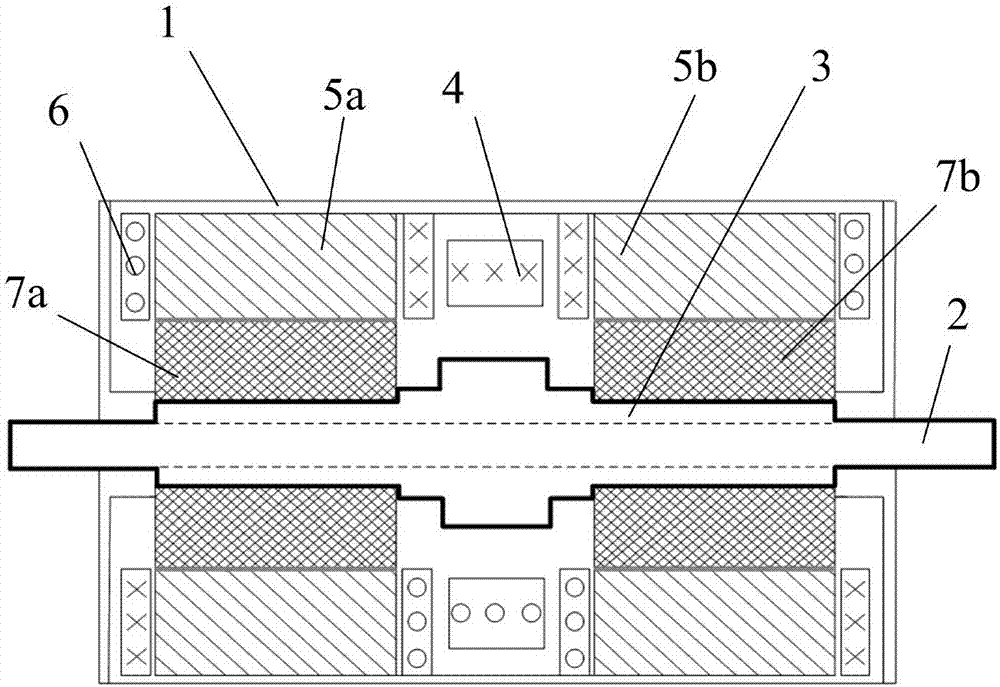

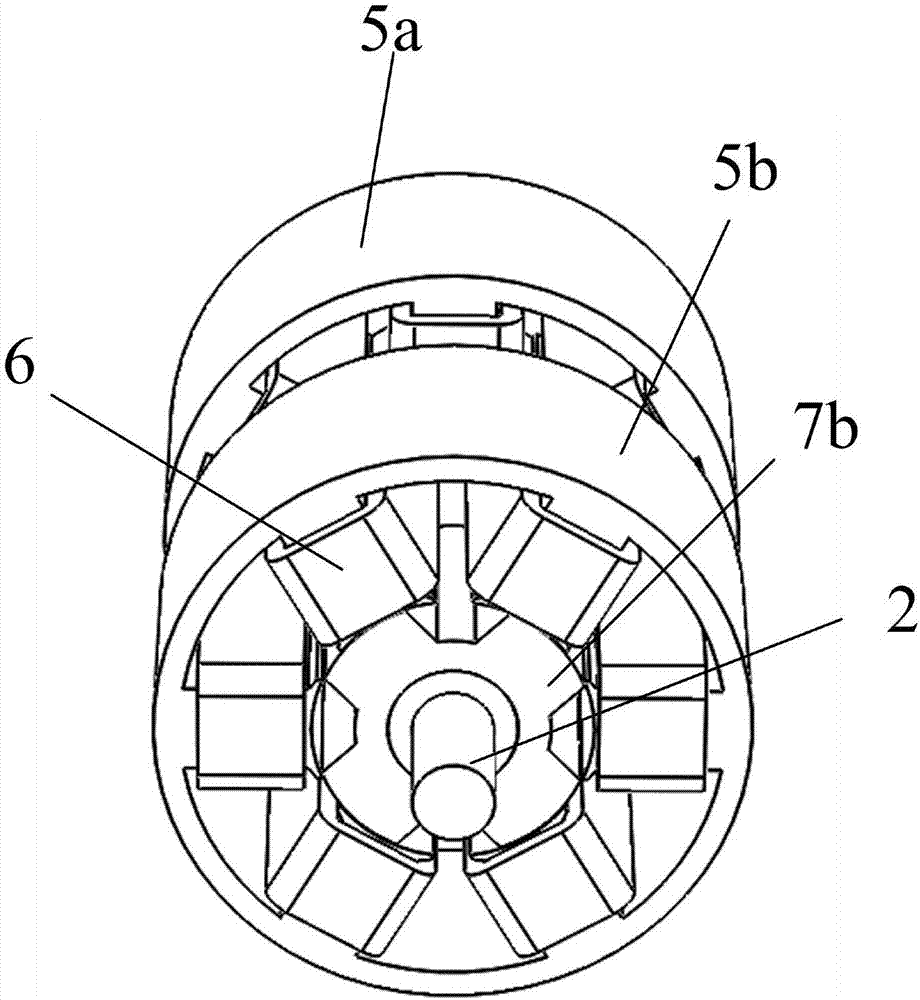

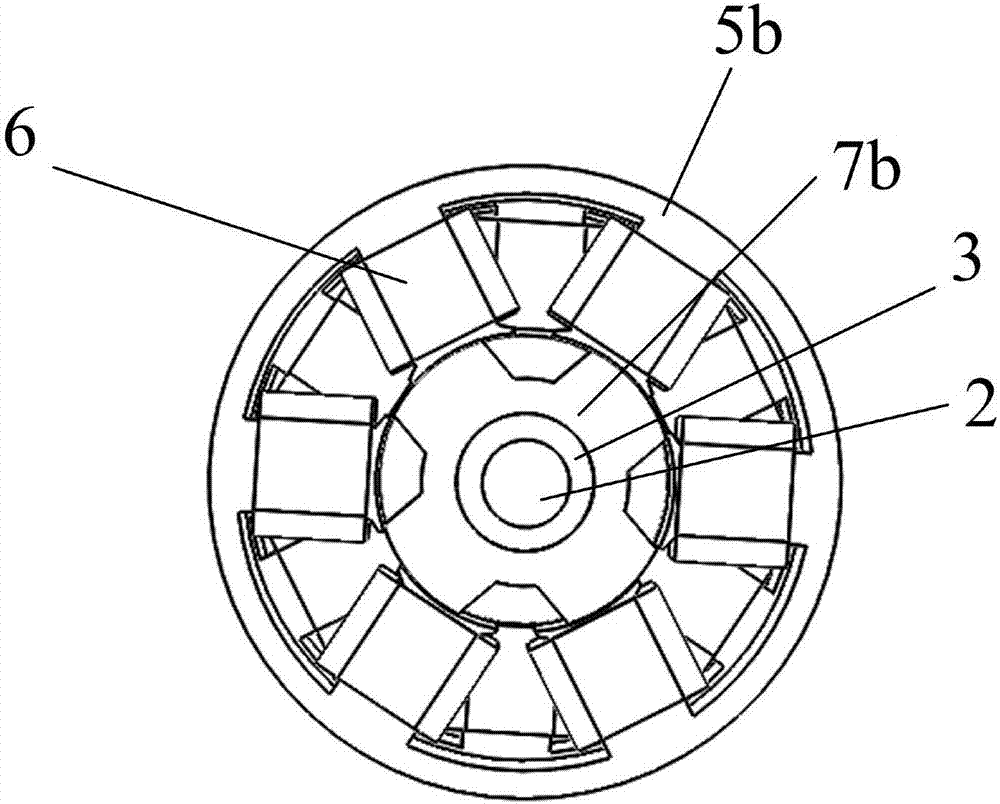

[0019] Such as figure 1 As shown, the asymmetric excitation stator staggered double salient pole motor of this embodiment includes: a motor casing 1, a motor shaft 2, a magnetic material 3 covering the motor shaft, a central electric excitation coil 4, and a first set of salient poles The stator 5a, the second set of salient pole stators 5b, the stator winding 6, the first set of salient pole rotors 7a and the second set of salient pole rotors 7b; one end of the motor housing is provided with a motor front end cover 8, and the other of the motor housing One end is provided with a motor rear end cover 9, the motor front end cover 8 and the motor rear end cover 9 are respectively provided with middle holes, one end of the motor shaft 2 passes through the middle hole of the motor front end cover 8, and the other end of the motor shaft 2 passes through the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com