Helmet flame resistance testing device and testing method

A test device and combustion-resistant technology, which is applied in the direction of measuring devices, electric devices, heat measurement, etc., can solve the problems of high cost and price, complex structure, etc., and achieve convenient testing, high degree of intelligence, and stable test conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

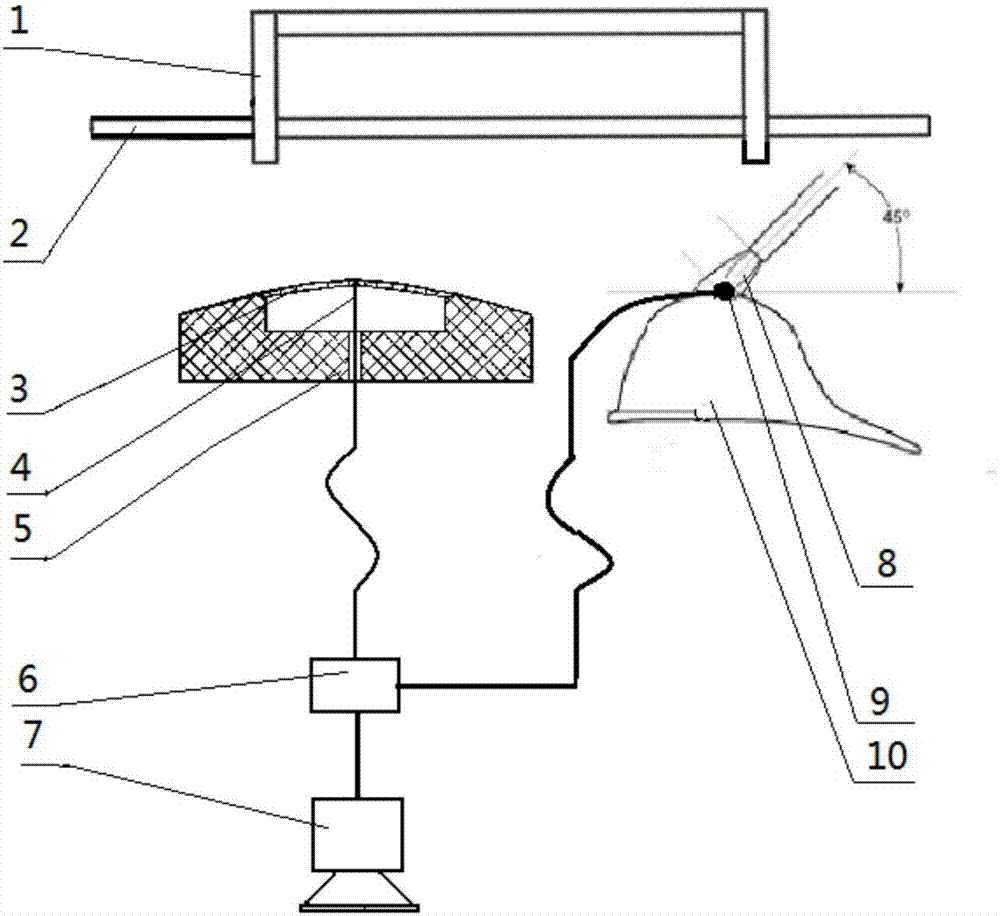

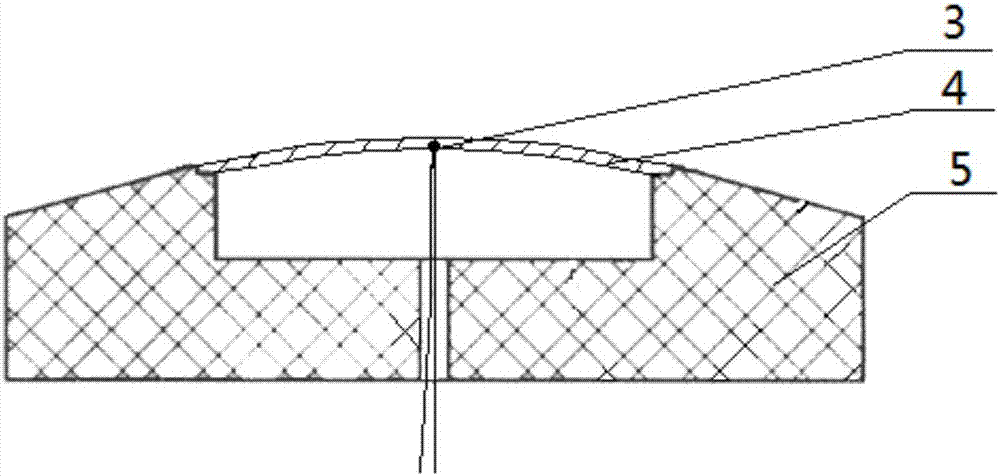

[0030] The fire helmet combustion resistance test device is composed of a combustion heat source, a radiation heat source, a copper plate calorimeter, a temperature measuring thermocouple, a data acquisition device and a data processing system.

[0031] Such as figure 1 As shown, the radiant heat source is composed of nine quartz heating tubes 2 and a support 1, placed above the sample, and generates heat radiation after being energized. In the circuit, the quartz heating tube 2 is also connected to a 380V power supply. The Bunsen burner 8 is installed above the side of the sample, and sprays flames to the sample at an angle of 45° to the vertical direction. Bunsen burner 8 orifice diameter is 13mm. Platinum-rhodium copper thermocouples are mounted on the helmet to be tested and connected to the data acquisition device.

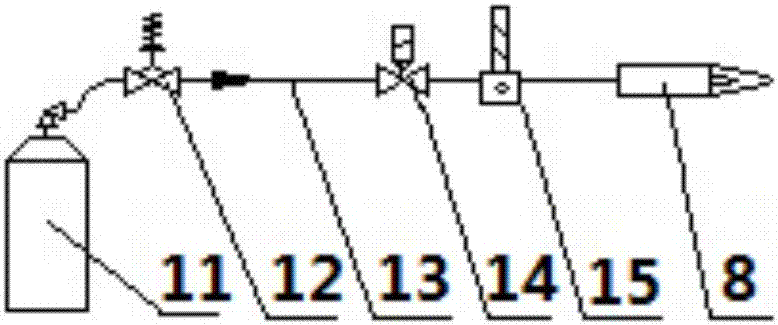

[0032] Such as figure 2 As shown, the combustion heat source is composed of a gas cylinder 11, a pressure regulating valve 12, a pipeline 13, a solenoid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com