Angle sliding rail connecting rod device

A connecting rod device and slide rail technology, which is applied to bearings, linear motion bearings, bearing components, etc., can solve the problems of small viewing angle between the platform and the human body, inconvenient use, and difficult to operate, and achieves simple platform fixing and unlocking. Fast, small footprint, convenient height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

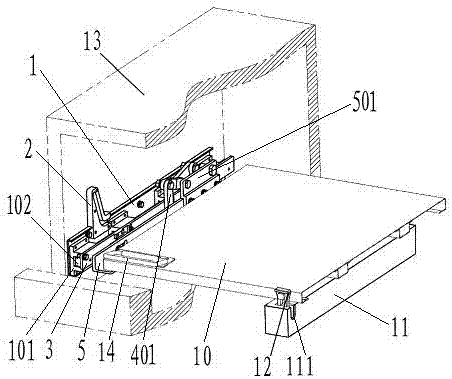

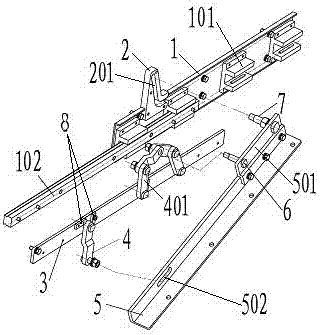

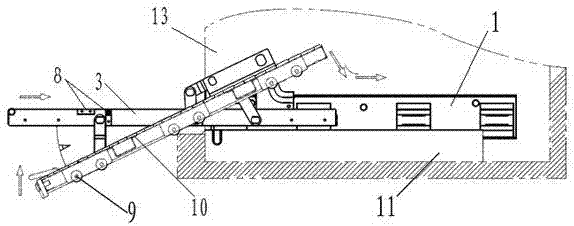

[0011] The present invention will be further described below in conjunction with drawings and embodiments. see Figure 1 to Figure 4 , the angle slide rail connecting rod device, comprising platform 10, slide rail 1, connecting rod 3 and connecting plate 5, slide rail 1 is symmetrically installed on the frame 13 wall panels on both sides of the platform 10; one end of the slide rail 1 A guide seat 2 is installed, and a guide groove 201 is provided on the inner side of the guide seat 2, and a draw-in groove 101 is installed on the inside of the slide rail 1, and a slide bar 102 is inserted in the draw-in slot 101, and the slide bar 102 is connected with the connecting rod 3; A connecting piece 4 is installed on the outer end of the connecting rod 3, and a linking assembly 401 is installed on the inner end, and a limit block 8 is arranged on the top and inside of the connecting piece 4, and the connecting piece 401 is formed by linking four connecting pieces 4. , the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com