An automatic water control valve for horizontal wells

A technology for water control valves and horizontal wells, applied in wellbore/well valve devices, wellbore/well parts, sealing/isolation, etc., can solve problems such as limited tool use and complicated operations, and increase flow resistance , Enhanced oil recovery and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

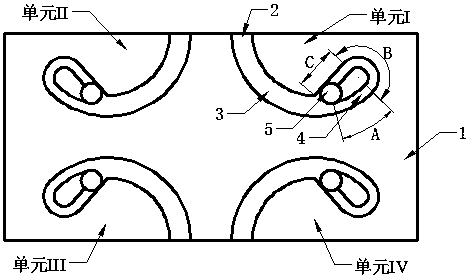

[0022] Explain in detail figure 1 Take unit I in as an example: when the oil-water mixed phase flows into the first-stage diversion tank 3 through the inlet 2, because the water phase density is higher than the oil phase, it will be separated into a single-phase oil-water phase by rotation, such as figure 2 As shown, the water phase is mainly concentrated on the outside of the primary diversion groove 3, and the oil phase is mainly concentrated on the inside of the primary diversion groove 3, and the closer to the outlet 5, the more fully the oil-water miscible phase separation; finally the oil phase directly along the outlet 5 flows out, the water phase will continue to flow along the secondary diversion groove 4 for a certain distance before flowing out along the outlet 5, which increases the frictional resistance of the water phase along the way, while the oil phase is not affected, thereby achieving the purpose of water control.

[0023] The inlet 2 and the outlet 5 of th...

Embodiment 2

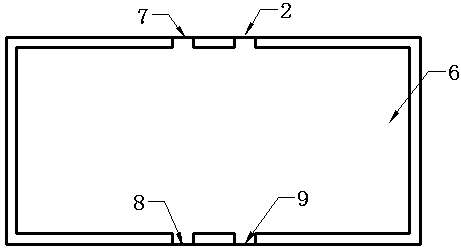

[0026] Explain in detail figure 1 as well as image 3 For example: such as figure 1 As shown, the valve base 1 has four identical units: I, II, III, and IV. Each unit can play a certain role in water control. When the four units are assembled together, the water control effect will be better, that is, a This kind of automatic water control valve for horizontal wells can achieve better water control effect in the unit area of the wellbore, and is suitable for wells with large liquid production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com