Adjustable vortex-preventing beam and construction method thereof

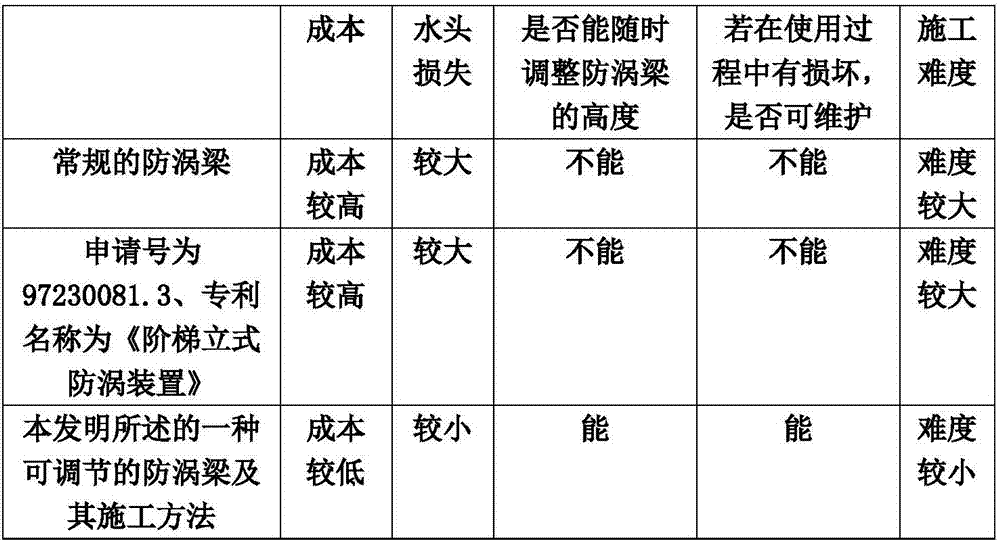

A construction method and adjustable technology, applied in sustainable manufacturing/processing, marine engineering, water conservancy engineering, etc., can solve the problems of complex structure, damage, increased water head loss, etc., to overcome the large fluctuation of reservoir water level, improve Water flow conditions, the effect of reducing head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

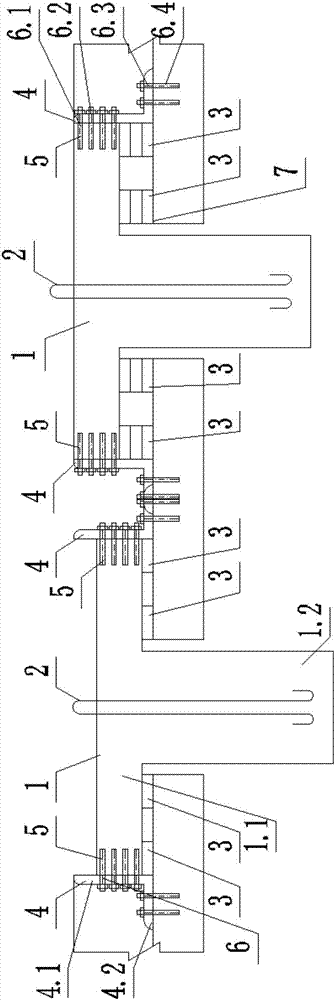

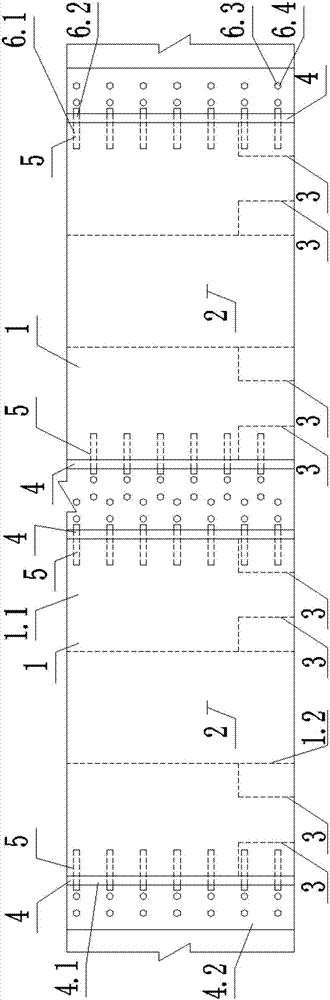

[0028]Referring to the accompanying drawings, it can be seen that an adjustable vortex-proof beam includes a prefabricated reinforced concrete beam 1, which is characterized in that it also includes a suspension ring 2 and a prefabricated concrete pad 3; the prefabricated reinforced concrete beam 1 is in a T-shaped structure, and one end of the suspension ring 2 is Buried in the prefabricated reinforced concrete beam 1, the other end protrudes from the upper end of the prefabricated reinforced concrete beam 1, the bolt holes 6 include the first bolt hole 6.1, the second bolt hole 6.2, the third bolt hole 6.3, and the fourth bolt hole 6.4, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com