Preparation technology of two-layered leather with high explosive force

A technology of preparation process and blasting force, which is applied in the field of leather, can solve the problems that cannot meet the practical requirements, and achieve the effect of strengthening softness, improving service life and increasing softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

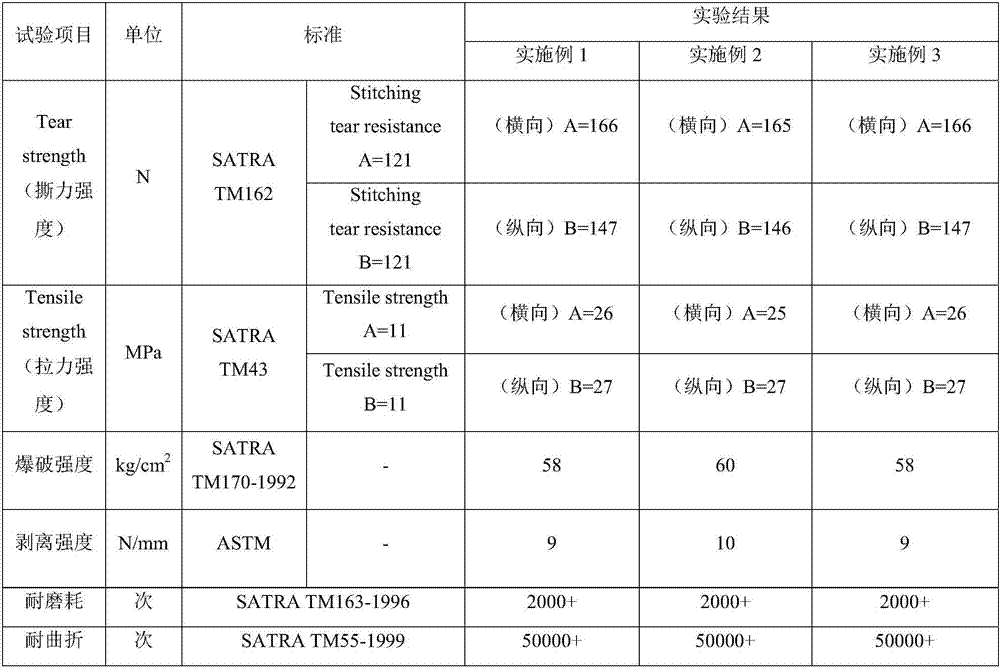

Examples

Embodiment 1

[0052] The preparation technology of two-layer leather with strong explosive force comprises the following steps:

[0053] Step 1, one return water:

[0054] Put the two-layer leather material in the drum for one backwater to obtain one backwater leather, wherein, the one backwater process is: add the following components according to the weight of the leather to the drum in turn for one backwater: 190% water, 0.4% soda ash and 0.1% degreasing agent, wherein, the temperature of the primary return water is 48°C, after 55 minutes of the primary return water, drain the drum, then add water to wash and drain.

[0055] Step 2, secondary water return:

[0056] The first backwater leather obtained in step 1 is subjected to secondary backwater to obtain the second backwater leather, wherein, the secondary backwater process is: sequentially add the following components according to the weight of the leather material to the drum for secondary backwater: 190% water, 0.4% soda ash and 0...

Embodiment 2

[0073] The preparation technology of two-layer leather with strong explosive force comprises the following steps:

[0074] Step 1, one return water:

[0075] Put the two-layer leather material in the drum for one backwater to obtain one backwater leather, wherein, the one backwater process is: add the following components according to the weight of the leather to the drum in turn for one backwater: 200% water, 0.5% soda ash and 0.2% degreasing agent, wherein, the temperature of the first return water is 45°C, after the first return water for 60 minutes, drain the drum, then add water to wash and drain.

[0076] Step 2, secondary water return:

[0077] The first backwater leather obtained in step 1 is subjected to secondary backwater to obtain the second backwater leather, wherein, the secondary backwater process is: sequentially add the following components according to the weight of the leather material to the drum for secondary backwater: 200% water, 0.5% soda ash and 0.15...

Embodiment 3

[0094] The preparation technology of two-layer leather with strong explosive force comprises the following steps:

[0095] Step 1, one return water:

[0096] Put the two-layer leather material in the drum for one backwater to obtain one backwater leather, wherein, the one backwater process is: add the following components according to the weight of the leather to the drum in turn for one backwater: 210% water, 0.6% soda ash and 0.3% degreasing agent, wherein, the temperature of the primary return water is 50°C, and after 65 minutes of primary return, the drum is drained, and then water is added for washing and draining;

[0097] Step 2, secondary water return:

[0098] The first backwater leather obtained in step 1 is subjected to secondary backwater to obtain the second backwater leather, wherein, the secondary backwater process is: sequentially add the following components according to the weight of the leather to the drum for secondary backwater: 210% water, 0.6% soda ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com