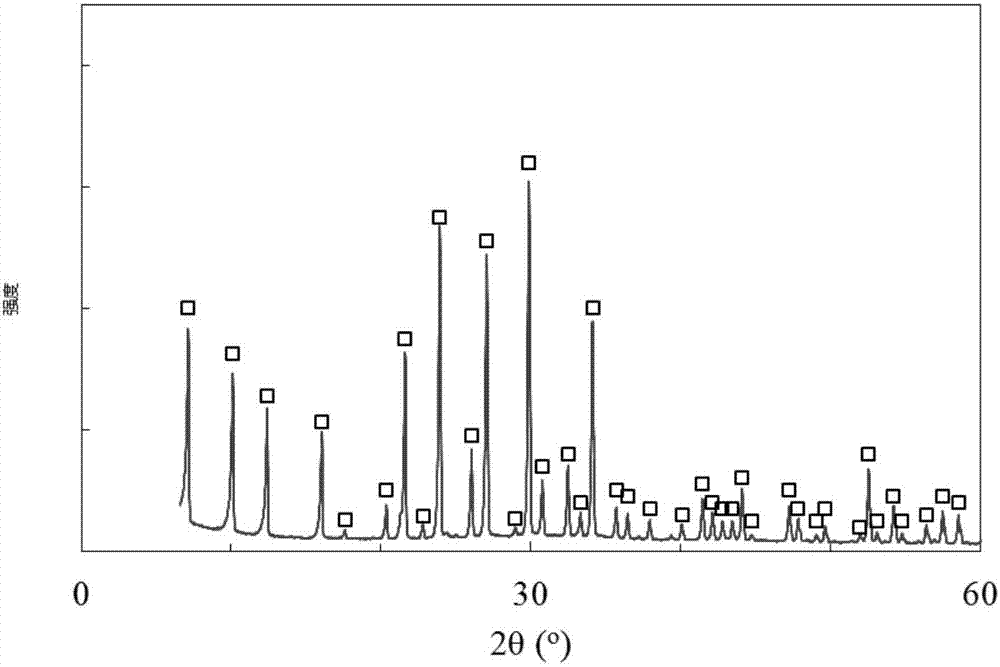

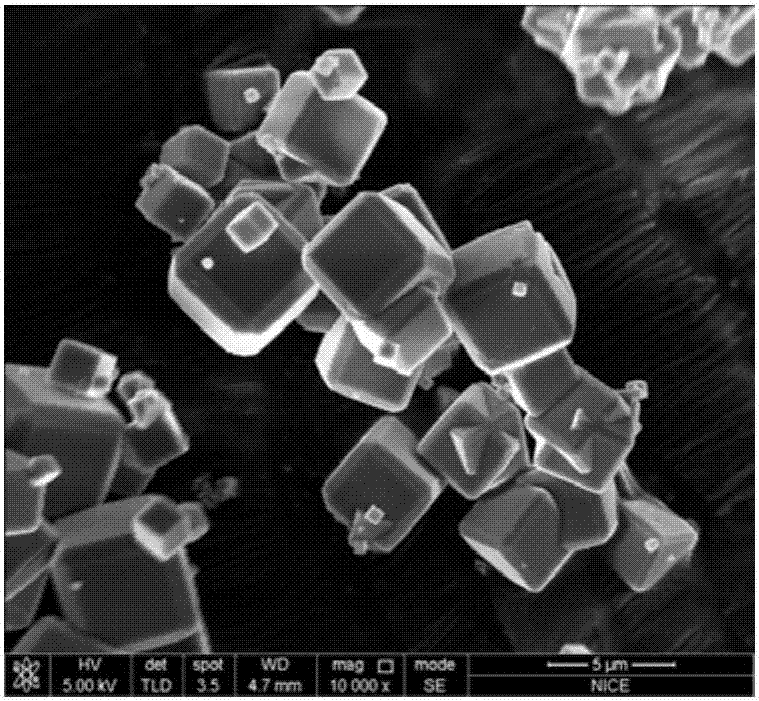

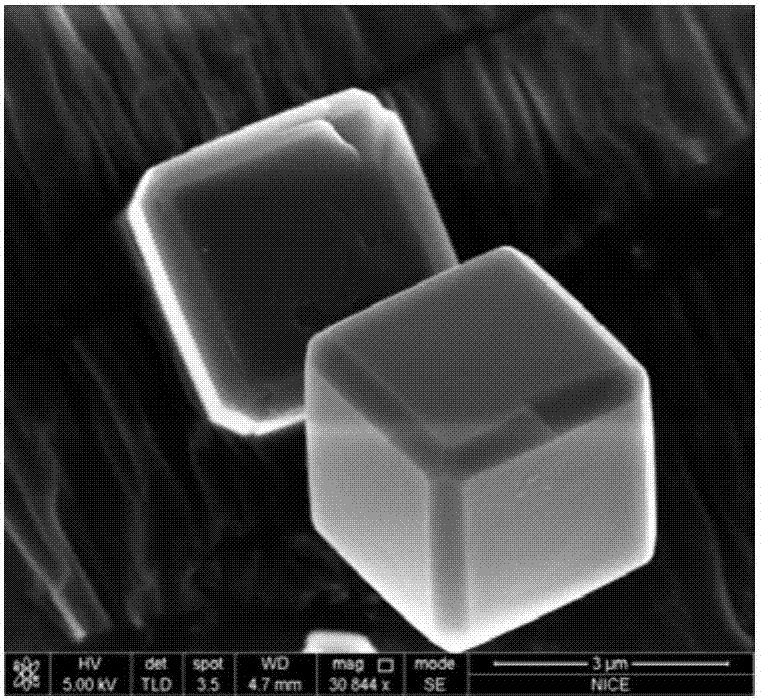

4A type molecular sieve and preparation method thereof

A molecular sieve and weight technology, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of 4A-type molecular sieves with low purity and crystallinity, so as to improve comprehensive utilization value, large economic benefits and Social benefits, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0044] According to a preferred embodiment, the method of the present invention comprises:

[0045] 1) reacting fly ash under acidic conditions to obtain a mixture;

[0046] 2) The mixture is filtered to obtain filter residue and AlCl respectively 3 Mother liquor;

[0047] 3) react the filter residue under alkaline conditions to obtain Na 2 SiO 3 Mother liquor;

[0048] 4) the AlCl 3 mother liquor and the Na 2 SiO 3 The mother liquor is mixed and reacted and crystallized in sequence;

[0049] 5) The product obtained after crystallization is successively filtered, washed and dried.

[0050] Each parameter in the above-mentioned preferred embodiment of the present invention is the same as the foregoing description of the present invention, and the present invention will not be repeated here, and those skilled in the art should not understand it as a limitation of the present invention.

[0051] In the second aspect, the present invention provides the 4A molecular sieve ...

Embodiment 1

[0066] 1. Place 100g of fly ash in 400g of 28% by weight hydrochloric acid aqueous solution to react, the reaction temperature is 80°C, and the time is 1h;

[0067] 2. Filter the mixture obtained after the reaction in step 1 to obtain AlCl as the filtrate respectively 3 Mother liquor and the acid-process aluminum extraction residue as filter residue, the composition and content (% by weight) of the acid-process aluminum extraction residue are shown in Table 2, and the AlCl 3 AlCl in mother liquor 3 The content is 225g / L;

[0068] 3. The filter residue was placed in 400 g of aqueous sodium hydroxide solution with a pH value of 12.0 for reaction, wherein the reaction temperature was 70° C. and the time was 0.5 h to obtain Na 2 SiO 3 mother liquor, the Na 2 SiO 3 mother liquor as SiO 2 The calculated content is 130g / L;

[0069] 4, the AlCl 3 mother liquor and the Na 2 SiO 3 The mother liquor is mixed and reacted, and the AlCl 3 Al 2 o 3 Gauge and the Na 2 SiO 3 mot...

Embodiment 2

[0076] 1. Place 100g of fly ash in 400g of 25% by weight hydrochloric acid aqueous solution to react, the reaction temperature is 60°C, and the time is 2h;

[0077] 2. Filter the mixture obtained after the reaction in step 1 to obtain AlCl as the filtrate respectively 3 Mother liquor and the acid-process aluminum extraction residue as filter residue, the composition and content (% by weight) of the acid-process aluminum extraction residue are shown in Table 2, and the AlCl 3 AlCl in mother liquor 3 The content is 218g / L;

[0078] 3. The filter residue was placed in 400 g of aqueous sodium hydroxide solution with a pH value of 13.0 for reaction, wherein the reaction temperature was 60° C. and the time was 1 h to obtain Na 2 SiO 3 mother liquor, the Na 2 SiO 3 mother liquor as SiO 2 The calculated content is 134g / L;

[0079] 4, the AlCl 3 mother liquor and the Na 2 SiO 3 The mother liquor is mixed and reacted, and the AlCl 3 Al 2 o 3 Gauge and the Na 2 SiO 3 mothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com