Indoor biological waste fertilizer pretreatment barrel

A bio-waste pretreatment technology, which is applied in the direction of trash bins, garbage collection, household appliances, etc., can solve the problems of increasing difficulty in sorting and processing, unclear classification of domestic waste, and difficulty in centralized processing, so as to ensure the effectiveness and The effects of safety, ease of vertical alignment connection, and reduction of centralized processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

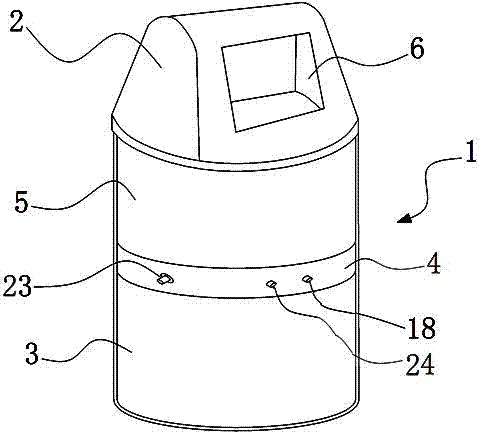

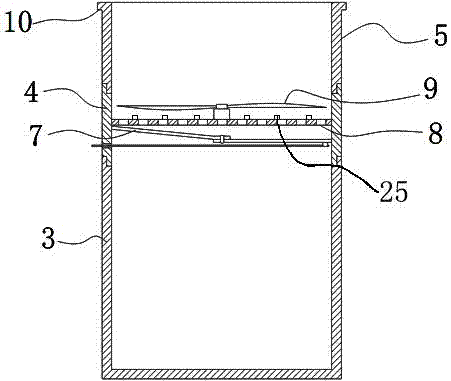

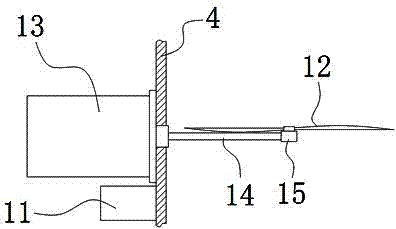

[0033] Such as figure 1 As shown, an indoor bio-waste fertilization pretreatment bucket includes a housing 1, a top cover 2, a non-porous partition 7, an electric heating grid 8 and a crushing and mixing assembly 9, and the housing 1 is circular in cross section. Barrel-shaped structure, the top cover 2 is fastened on the top of the shell 1, the top cover 2 is provided with a garbage inlet 6, and the shell 1 is sequentially fixed with a disposal storage room 3, a lower garbage room 4 and an upper garbage room 5 from bottom to top. Such as figure 2 As shown, in the lower part 4 of the garbage chamber, a non-porous partition 7, an electric heating screen 8 and a pulverizing and stirring assembly 9 are installed sequentially from bottom to top, as shown in FIG. Figure 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com