Vertical case packer

A cartoning machine and vertical technology, applied in the field of vertical cartoning machines, can solve the problems of large area of vertical cartoning, large equipment area and high cost of vertical cartoning, so as to improve efficiency and reduce costs. Small footprint and the effect of saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

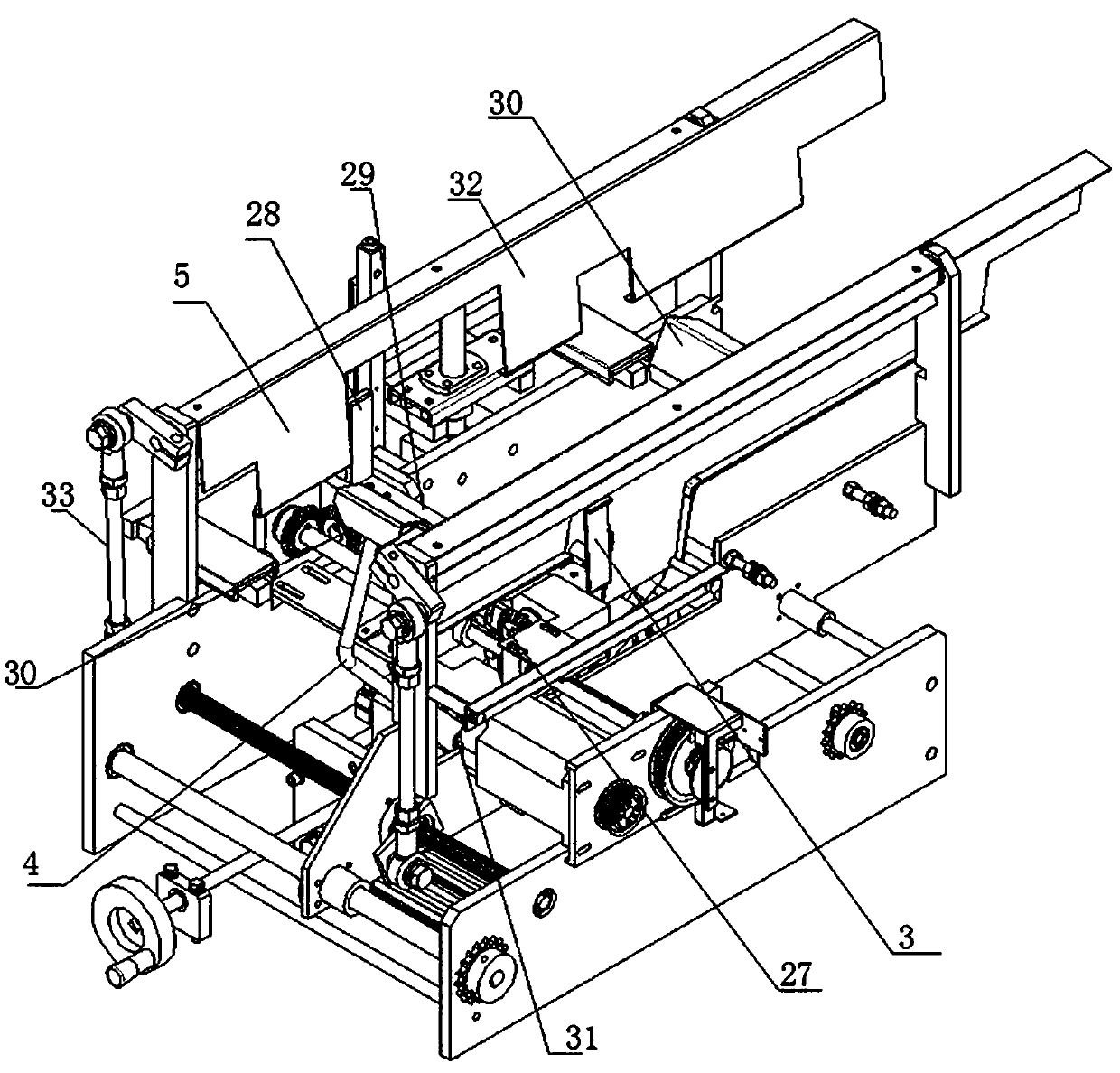

[0054] As a preferred embodiment of the present invention, with reference to the attached Figure 1-7 , this example discloses:

[0055] Vertical box packing machine, including box storage mechanism 1, box opening mechanism 2, pre-folding long leaf turning mechanism 3, short leaf folding mechanism 4, long leaf folding mechanism 5, box conveying mechanism 6, box positioning mechanism 7 and two Shaft-parallel manipulator mechanism 8, the box storage mechanism 1 is arranged on one side of the box opening mechanism 2, there is a height difference between the box storage mechanism 1 and the box body conveying mechanism 6, the direction of the delivery box body of the box storage mechanism 1 It is perpendicular to the conveying direction of the box conveying mechanism 6; the box conveying mechanism 6 extends from the unpacking mechanism 2 to the box positioning mechanism 7, and the box conveying mechanism 6 forms a box conveying channel 9; the unpacking Mechanism 2 is arranged at o...

Embodiment 2

[0058] As another preferred embodiment of the present invention, with reference to the attached Figure 1-7 , this example discloses:

[0059]Vertical box packing machine, including box storage mechanism 1, box opening mechanism 2, pre-folding long leaf turning mechanism 3, short leaf folding mechanism 4, long leaf folding mechanism 5, box conveying mechanism 6, box positioning mechanism 7 and two Shaft-parallel manipulator mechanism 8, the box storage mechanism 1 is arranged on one side of the box opening mechanism 2, there is a height difference between the box storage mechanism 1 and the box body conveying mechanism 6, the direction of the delivery box body of the box storage mechanism 1 It is perpendicular to the conveying direction of the box conveying mechanism 6; the box conveying mechanism 6 extends from the unpacking mechanism 2 to the box positioning mechanism 7, and the box conveying mechanism 6 forms a box conveying channel 9; the unpacking Mechanism 2 is arranged...

Embodiment 3

[0063] As another preferred embodiment of the present invention, with reference to the attached Figure 1-8 , this example discloses:

[0064] Vertical box packing machine, including box storage mechanism 1, box opening mechanism 2, pre-folding long leaf turning mechanism 3, short leaf folding mechanism 4, long leaf folding mechanism 5, box conveying mechanism 6, box positioning mechanism 7 and two Shaft-parallel manipulator mechanism 8, the box storage mechanism 1 is arranged on one side of the box opening mechanism 2, there is a height difference between the box storage mechanism 1 and the box body conveying mechanism 6, the direction of the delivery box body of the box storage mechanism 1 It is perpendicular to the conveying direction of the box conveying mechanism 6; the box conveying mechanism 6 extends from the unpacking mechanism 2 to the box positioning mechanism 7, and the box conveying mechanism 6 forms a box conveying channel 9; the unpacking Mechanism 2 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com