A kind of blue light blocking film and preparation method thereof

A barrier film and blue light technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of monotonous absorbing barrier components, insufficient blue light absorption efficiency, and no good solution to LED lighting blue light problems and other problems, to achieve the effect of ensuring the quality of light output and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A blue light blocking film, comprising a base layer, a blue light blocking layer and a blue light dispersion absorbing layer, the blue light blocking layer is arranged on the base layer, and the blue light dispersion absorbing layer is arranged on the blue light blocking layer.

[0050] The base layer is made of a polycarbonate substrate mixed with blue light absorbing pigments through mixing injection molding, extrusion and stretching, wherein the amount of blue light absorbing pigments added to the polycarbonate substrate is 0.005% by weight of the substrate, the blue light absorbing pigment is C 28 h 19 N 5 Na 2 o 6 S 4 It is prepared by mixing with 1-phenyl-3-methyl-5-pyrazolone at a mass ratio of 0.8:1.

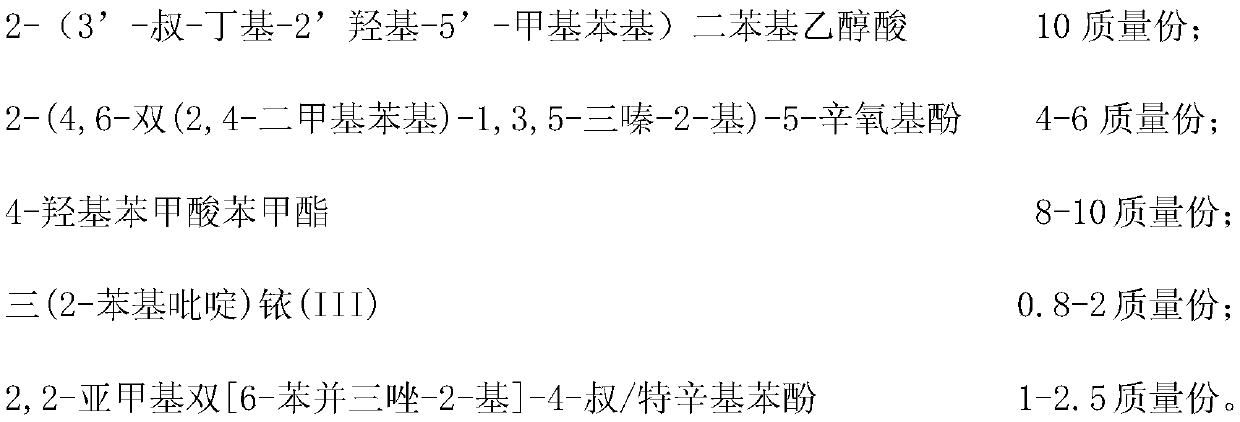

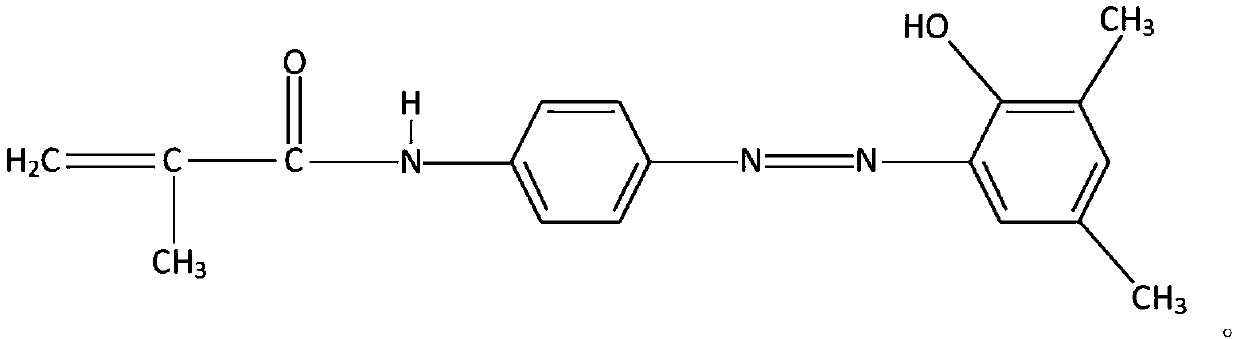

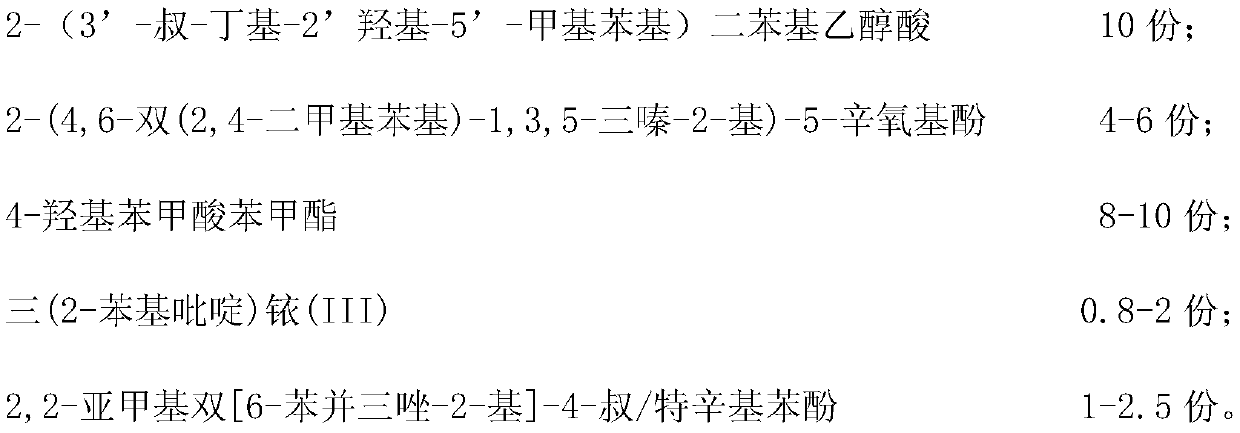

[0051] The blue light blocking layer is prepared by kneading epoxy resin modified polycarbonate and blue light blocking agent. The polycarbonate modified by epoxy resin consists of 100 parts by weight of polycarbonate, 20 parts by weight of polysulfone modif...

Embodiment 2

[0057] A blue light blocking film, comprising a base layer, a blue light blocking layer, a blue light dispersion absorbing layer, a UV hardening layer and an anti-scratch layer, the blue light blocking layer is arranged on the base layer, and the blue light dispersion absorbing layer is arranged on the On the blue light blocking layer, the UV hardening layer is set on the blue light dispersion absorbing layer, and the anti-scratch layer is set on the UV hardening layer.

[0058] The base layer is made of a polymethyl methacrylate substrate mixed with blue light absorbing pigments through mixing injection molding, extrusion and stretching, wherein the blue light absorbing pigments in the polymethyl methacrylate substrate The addition amount is 0.01% of the weight of the polymethyl methacrylate substrate, and the blue light absorbing pigment is 2,2'-(1-triazine-1,3-diyldi-4,1-phenylene)bis (6-Methyl-7-benzothiazolesulfonic acid) disodium salt is prepared by mixing 1-phenyl-3-met...

Embodiment 3

[0066] A blue light barrier film, comprising a release protective layer, a base layer, a blue light barrier layer, a blue light dispersion absorbing layer, a UV hardening layer and an anti-scratch layer, one side of the base layer is provided with a release protective layer, and the base layer The other side is provided with a blue light blocking layer, the blue light dispersion absorbing layer is disposed on the blue light blocking layer, the UV hardening layer is disposed on the blue light dispersion absorbing layer, and the anti-scratch layer is disposed on the UV hardened layer.

[0067] The base layer is made of a polyethylene terephthalate substrate mixed with blue light absorbing pigments through mixing injection molding, extrusion and stretching, wherein the blue light absorbing pigments are mixed with polyethylene terephthalate The amount added to the alcohol ester substrate is 0.008% of the weight of the polyethylene terephthalate substrate, and the blue light absorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com