Heavy metal contaminated soil remediation agent, application thereof and contaminated soil remediation method

A soil remediation agent and a technology for polluted soil, which is applied in the field of heavy metal-contaminated soil remediation agent and its remediation and remediation of contaminated soil, can solve the problems of poor long-term remediation effect, secondary pollution of soil, single heavy metal, etc., and achieve improved adhesion and Water holding capacity, good repairing effect, effect of enhancing ionic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

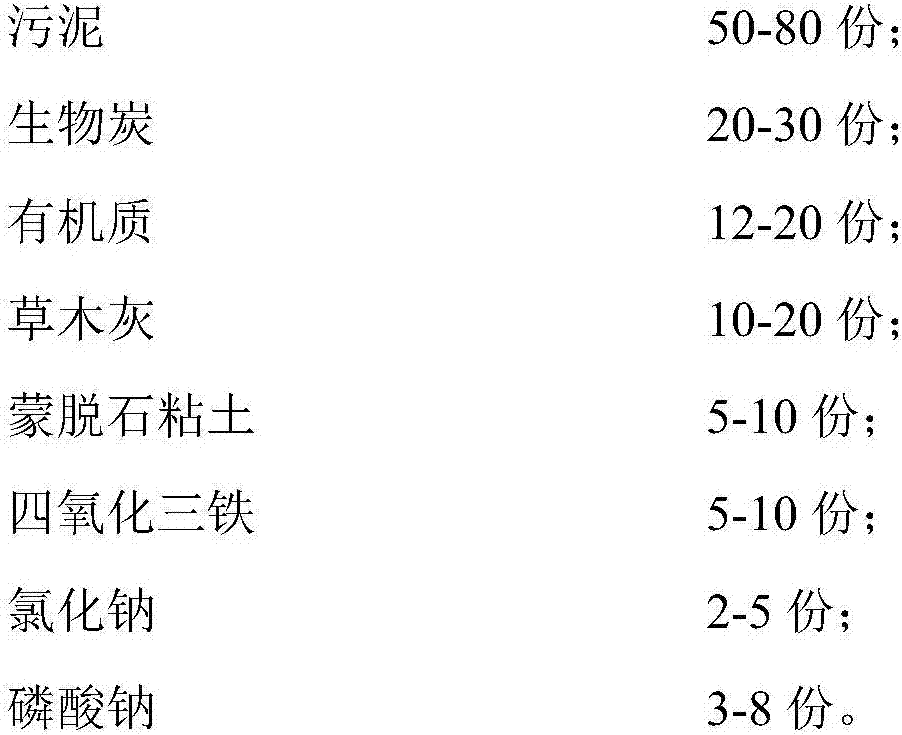

[0040] A heavy metal contaminated soil restoration agent, comprising the following components in parts by weight:

[0041]

[0042] Wherein, the sludge is the sludge reaching the standard of the sewage treatment plant, and the humidity of the sludge is 52%.

[0043] The preparation process of biochar is as follows: adding crop stalks and fruit husks into a pyrolysis reactor, raising the temperature to 380°C under anaerobic conditions, performing a pyrolysis carbonization reaction, and reacting for 1.5 hours to obtain biochar.

[0044] The method for repairing heavy metal-contaminated soil by the above-mentioned soil remediation agent comprises the following steps:

[0045] (1) Take sludge, biochar, humus, plant ash, montmorillonite clay, ferric oxide and humic acid in a mixer, stir and mix evenly to obtain a mixture;

[0046] (2) dissolving sodium chloride and sodium phosphate in water to obtain a mixed aqueous solution; wherein, the amount of water used to dissolve sodium...

Embodiment 2

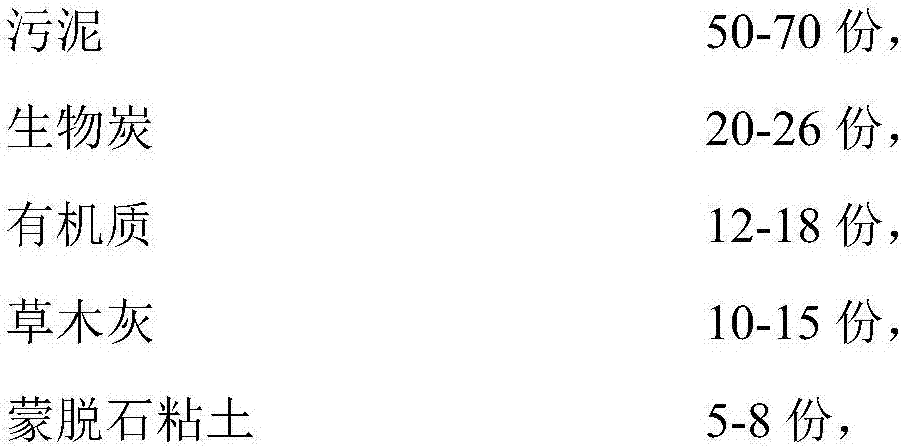

[0051] A heavy metal contaminated soil remediation agent, comprising the following components in parts by weight:

[0052]

[0053] Wherein, the sludge is the sludge reaching the standard of the sewage treatment plant, and the humidity of the sludge is 47%.

[0054] The preparation process of biochar is as follows: adding crop stalks and fruit husks into a pyrolysis reactor, raising the temperature to 365°C under anaerobic conditions, performing a pyrolysis carbonization reaction, and reacting for 1.5 hours to obtain biochar.

[0055] The method for remediating heavy metal-contaminated soil with the above-mentioned soil remediation agent comprises the following steps:

[0056] (1) Take sludge, biochar, humus, plant ash, montmorillonite clay, ferric oxide and humic acid in a mixer, stir and mix evenly to obtain a mixture;

[0057] (2) dissolving sodium chloride and sodium phosphate in water to obtain a mixed aqueous solution; wherein, the amount of water used to dissolve sodi...

Embodiment 3

[0062] A heavy metal contaminated soil restoration agent, comprising the following components in parts by weight:

[0063]

[0064] Wherein, the sludge is the sludge reaching the standard of the sewage treatment plant, and the humidity of the sludge is 40%.

[0065] The preparation process of biochar is as follows: adding fruit shells and wood waste into a pyrolysis reactor, raising the temperature to 350°C under anaerobic conditions, and performing a pyrolysis carbonization reaction for 2 hours to obtain biochar.

[0066] The method for remediating heavy metal-contaminated soil with the above-mentioned soil remediation agent comprises the following steps:

[0067] (1) Take sludge, biochar, humus, plant ash, montmorillonite clay, ferric oxide and humic acid in a mixer, stir and mix evenly to obtain a mixture;

[0068] (2) dissolving sodium chloride and sodium phosphate in water to obtain a mixed aqueous solution; wherein, the amount of water used to dissolve sodium chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com