Pre-selected supplementary vibration plate

A vibrating plate and filling technology, which is applied in the direction of solid separation, classification, and separation of solids from solids with airflow, etc., can solve the problems of low feeding efficiency, inability to meet customer needs for efficient feeding, and large gaps between workpieces, etc. , to achieve the effect of improving efficiency, facilitating large-scale promotion and application, and high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

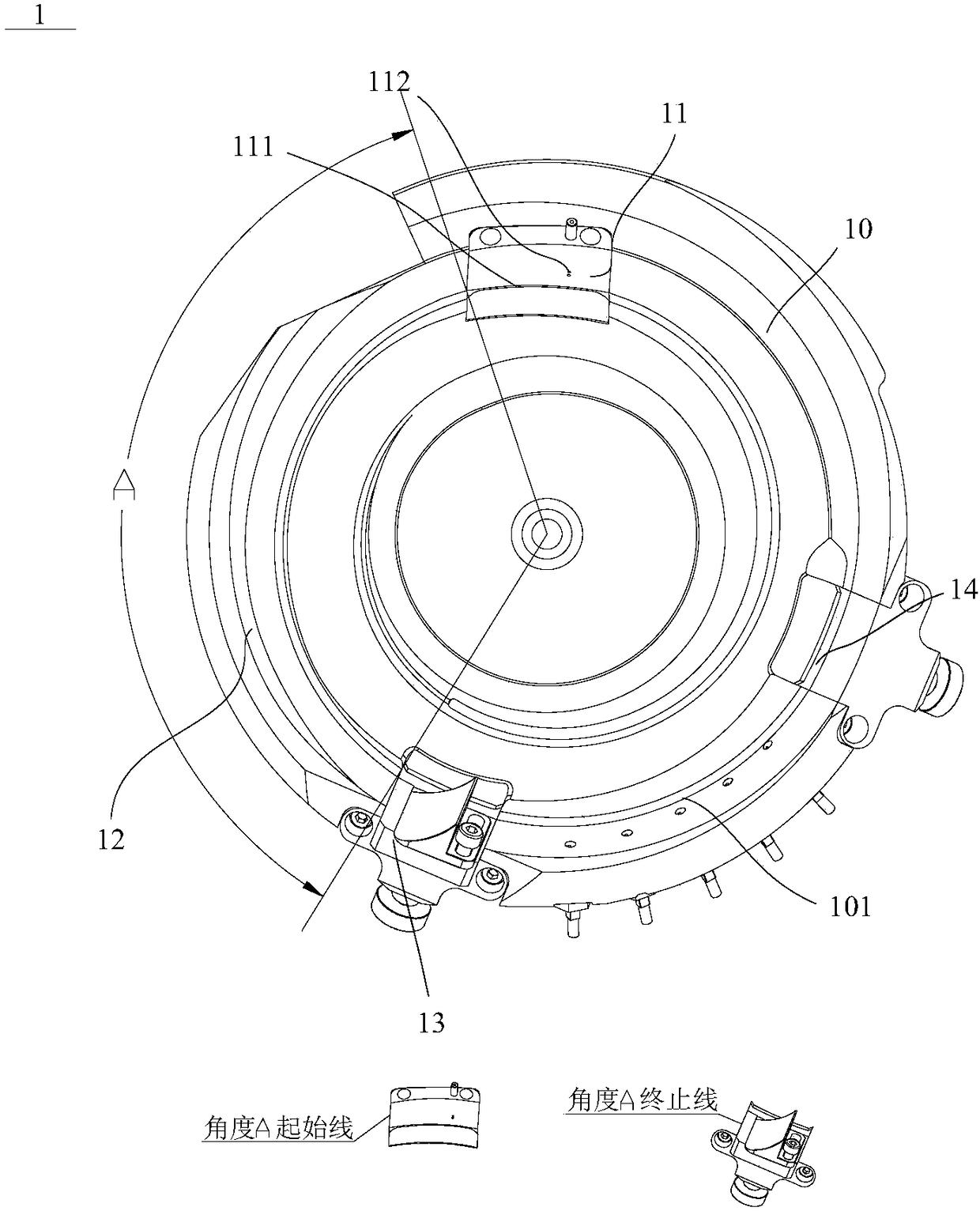

[0031] The concrete structure of this embodiment is as figure 1 as shown, figure 1 It is a structural schematic diagram of a pre-selected supplementary vibrating plate according to an exemplary embodiment of the present invention. The vibration supplementary vibrating plate 1 in this embodiment includes a disc body 10, the disc body 10 is a disc-shaped structure, and has a groove inside it, and the outer diameter of the disc body 10 is usually less than 450 mm, even less than 350 mm, for example 300 mm. A helical vibrating feeding channel 101 is formed on the groove of the disc body 10, and the overall shape of the vibrating feeding channel 101 is as follows: Figure 4 . The vibrating feeding channel 101 is a continuous channel, and its section is as Figure 5 As shown, the first wall surface 1011 and the second wall surface 1012 are included, and a V-shaped structure is formed between the first wall surface 1011 and the second wall surface 1012, and the included angle of ...

no. 2 example

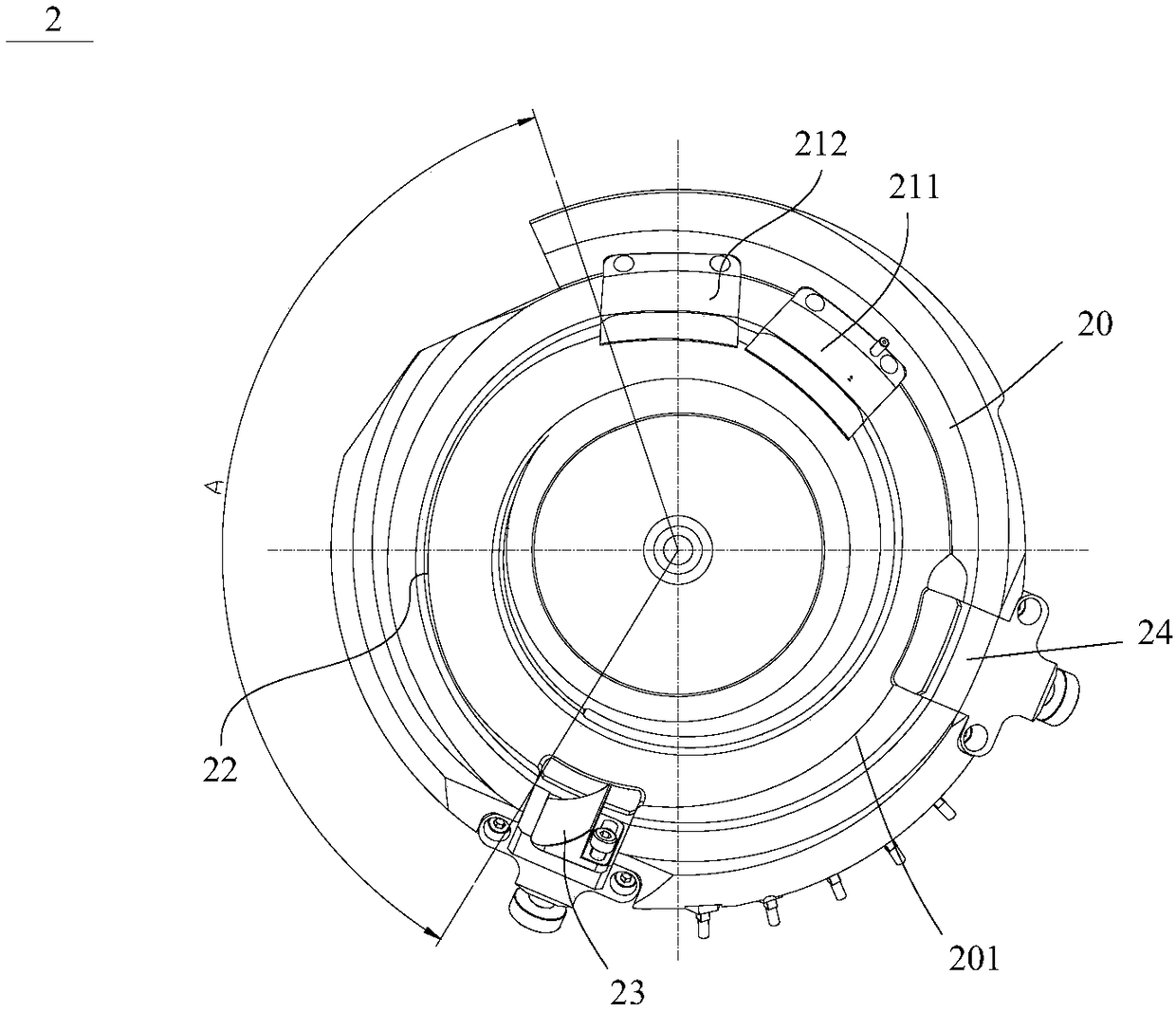

[0039] The concrete structure of this embodiment is as figure 2 as shown, figure 2 It is a structural schematic diagram of a pre-selected supplementary vibrating plate according to another exemplary embodiment of the present invention. The vibration supplementary vibrating plate 2 in this embodiment includes a disc body 20, the disc body 20 is a disc-shaped structure, has a groove inside it, and the outer diameter of the disc body 20 is usually less than 450 mm, even less than 350 mm, for example 300 mm. A spiral vibrating feeding channel 201 is formed on the groove of the disc body 20, and the overall shape of the vibrating feeding channel 201 is as follows: Figure 4 or Figure 5 shown. The vibrating feeding channel 201 is a continuous channel with a V-shaped cross section, and the included angle of the V-shaped structure is 90°±10°.

[0040] In this embodiment, a first preselection mechanism 211 , a second preselection mechanism 212 , a supplementary structure 22 , a...

no. 3 example

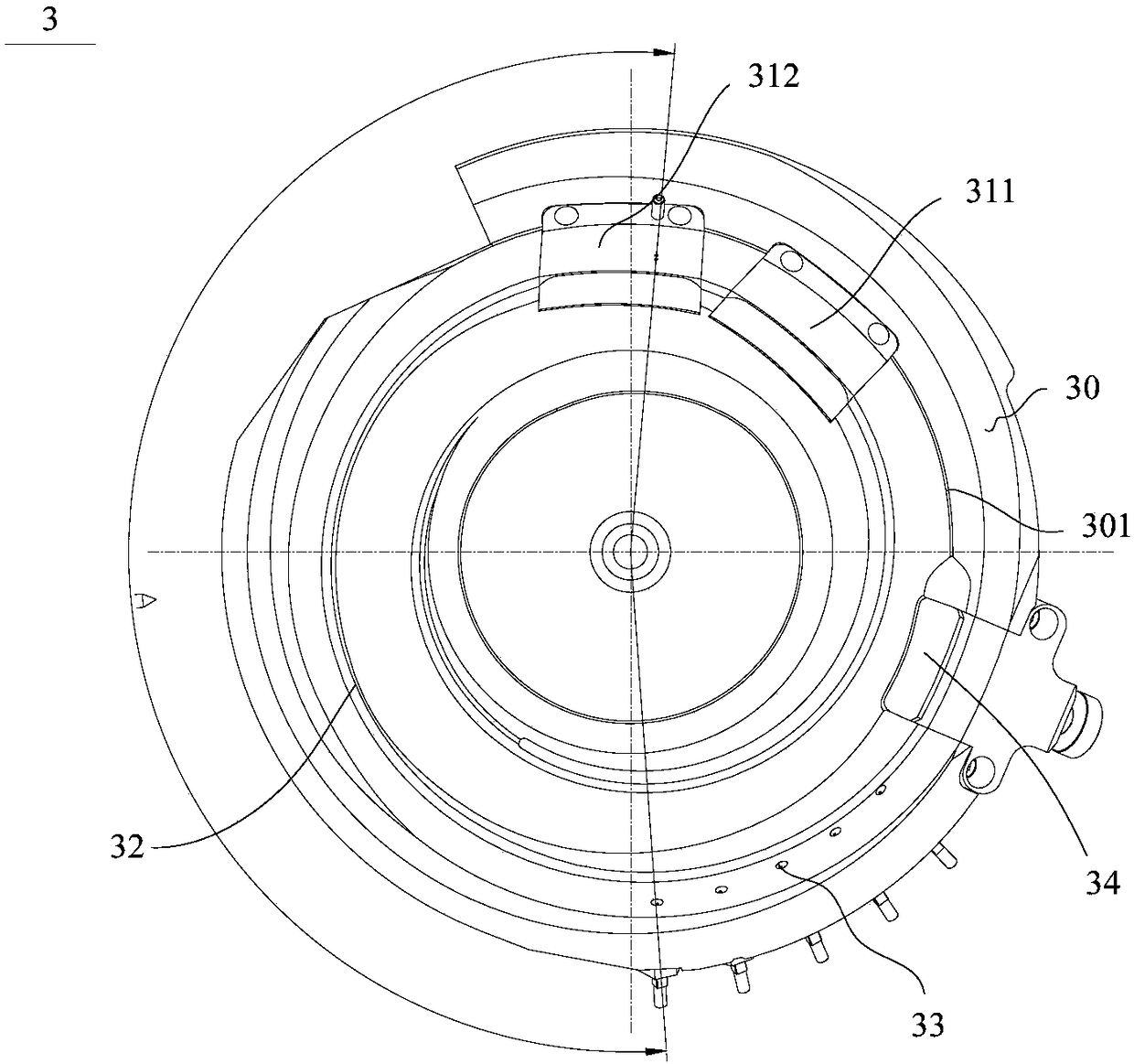

[0045] The concrete structure of this embodiment is as image 3 as shown, image 3 It is a structural schematic diagram of a pre-selected supplementary vibrating plate according to another exemplary embodiment of the present invention. The vibration supplementary vibrating plate 3 in this embodiment includes a disc body 30, the disc body 30 is a disc-shaped structure, has a groove inside it, and the outer diameter of the disc body 30 is usually less than 450 mm, even less than 350 mm, for example 300 mm. On the groove of disc body 30, be formed with spiral vibration feeding channel 301, the overall shape of vibration feeding channel 301 is as follows: Figure 4 or Figure 5 shown. The vibrating feeding channel 301 is a continuous channel with a V-shaped cross section, and the included angle of the V-shaped structure is 90°±10°.

[0046] In this embodiment, a first preselection mechanism 311 , a second preselection mechanism 312 , a supplementary structure 32 , a height se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com