Cable trench assembly

A technology for cable trenches and components, applied in electrical components and other directions, can solve the problems of cumbersome construction procedures, high costs, and many construction materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

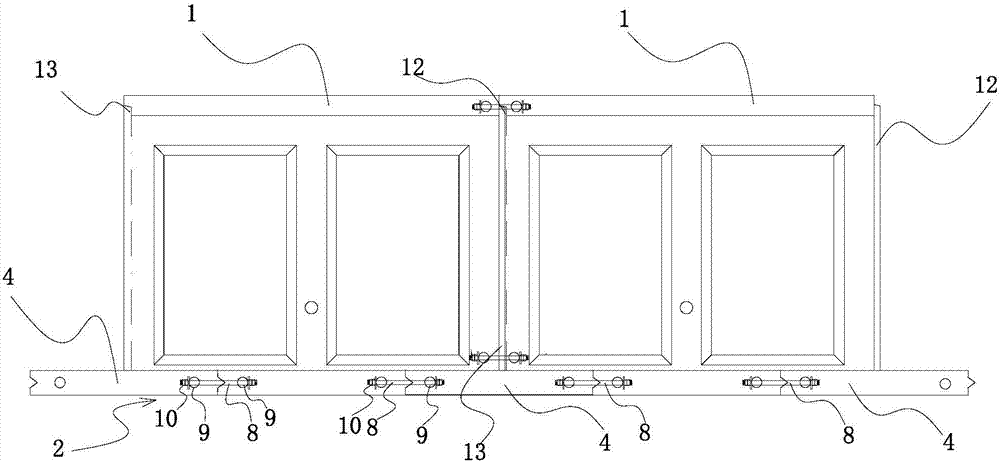

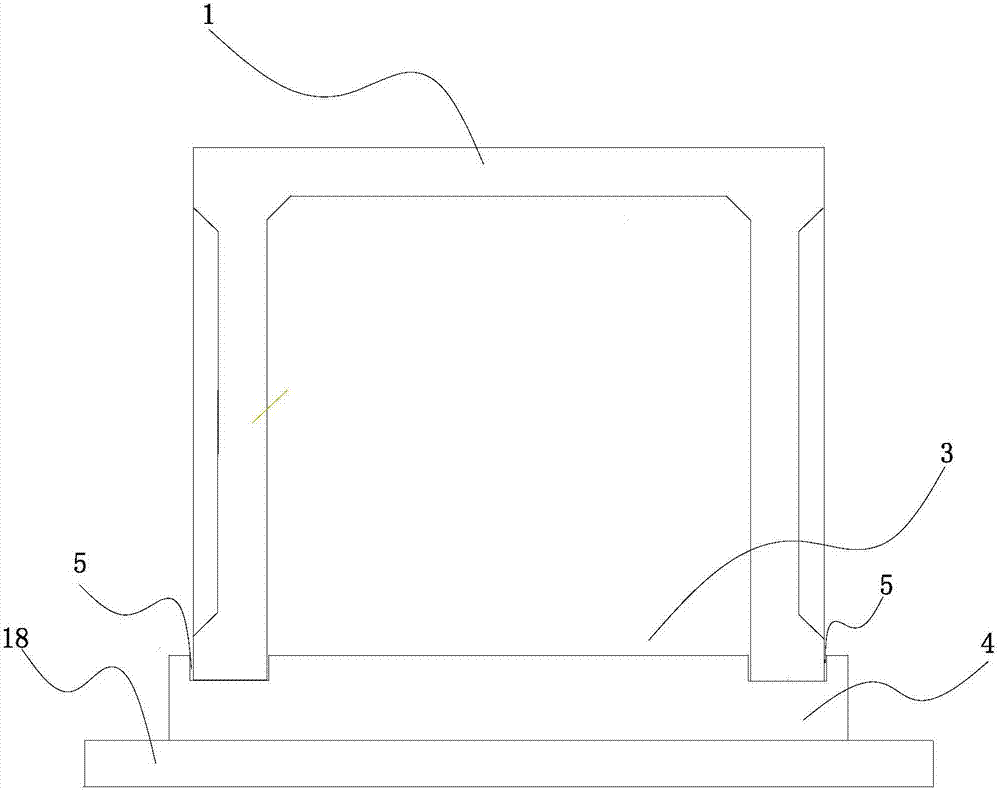

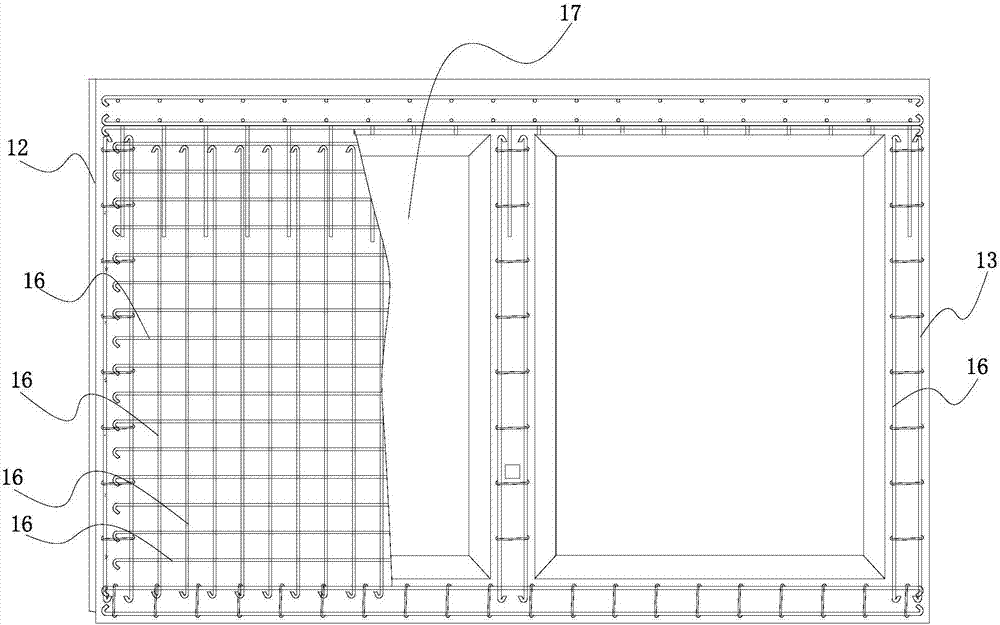

[0038] The following with attached Figure 1 to Figure 12 A cable groove body assembly of the present invention will be further described in detail.

[0039] A cable groove body assembly of the present invention, please refer to Figure 1 to Figure 12In each of the relevant figures, it includes at least two cable trench units 1 and a bottom plate assembly 2, the adjacent cable trench units 1 are horizontally detachable butt joint sealed and fixed, and the bottom plate assembly 2 is detachably fixed on the ground or installed On the surface, the lower part of the cable trench unit 1 is detachably sealed and fixed on the upper part of the bottom plate assembly 2, the lower part of the cable trench unit 1 is provided with a groove opening 3, and the upper part of the bottom plate assembly 2 is near the middle The location is within the groove opening 3 . In this way, when old cable trenches and old cable lines are rebuilt, or when there are already immovable facilities (such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com