An ultraviolet led epitaxial structure

An epitaxial structure, ultraviolet technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low quantum efficiency and low emission power in ultraviolet LEDs, reduce the quantum confinement Stark effect, increase the hole injection rate, The effect of the best luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] As mentioned in the background section, the internal quantum efficiency and emission power of AlGaN-based ultraviolet LEDs in the prior art are relatively low.

[0028] At present, the main reasons for the low luminous efficiency of AlGaN-based ultraviolet LED light sources are: the low carrier injection efficiency of AlGaN materials with high Al composition, which restricts the improvement of quantum efficiency in ultraviolet LEDs; the structural properties of AlGaN materials with high Al composition determine their light emission low efficiency.

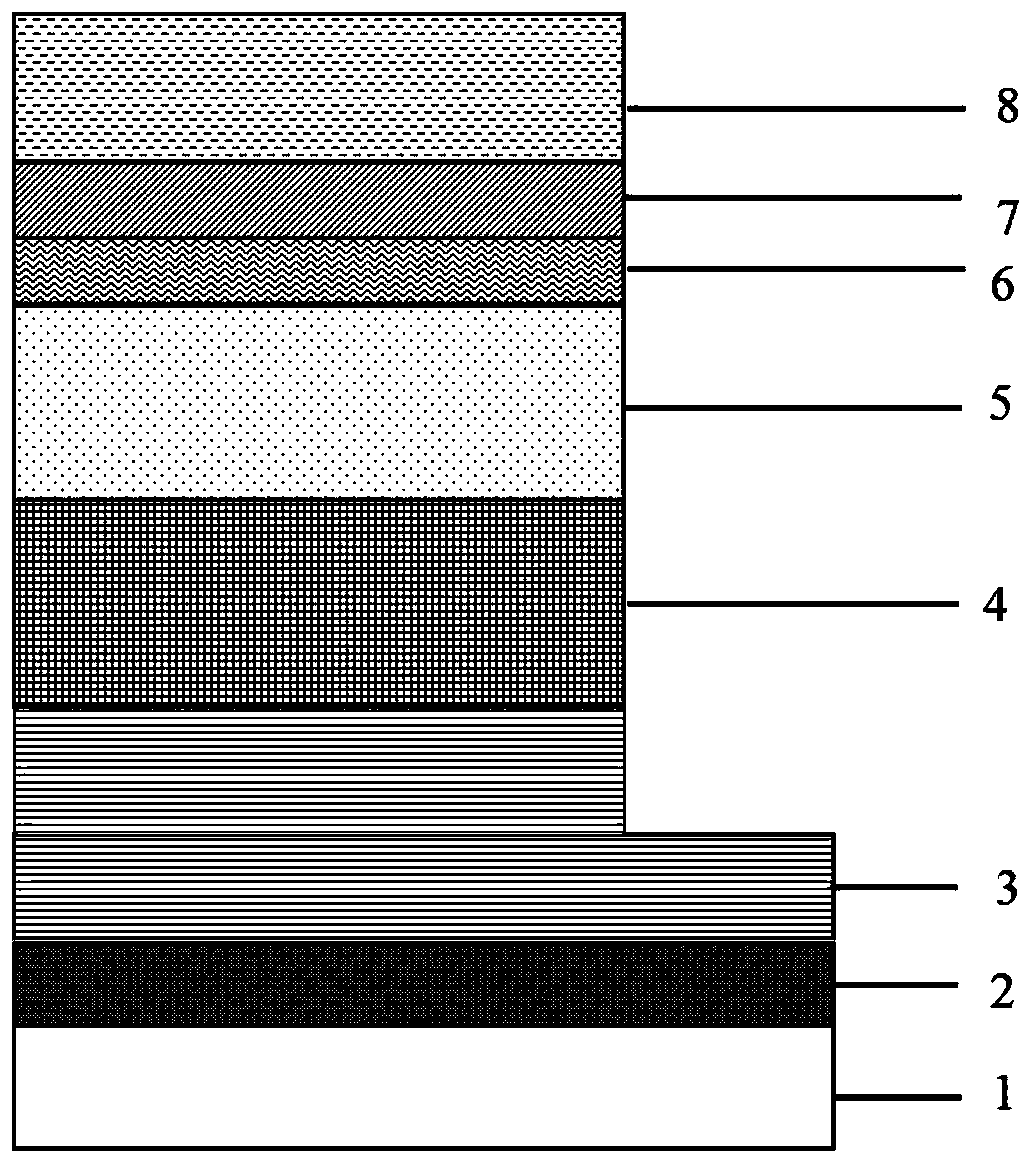

[0029] Based on this, the present invention provides a kind of ultraviolet LED epitaxial structure, it is characterized in that, comprises:

[0030] Substrate;

[0031] An undoped buffer layer, an N-type AlGaN layer, a multi-quantum well structure, a superlattice structure, an electron blocking layer, a P-type AlGaN layer, and a P-type GaN layer are sequentially grown on the substrate;

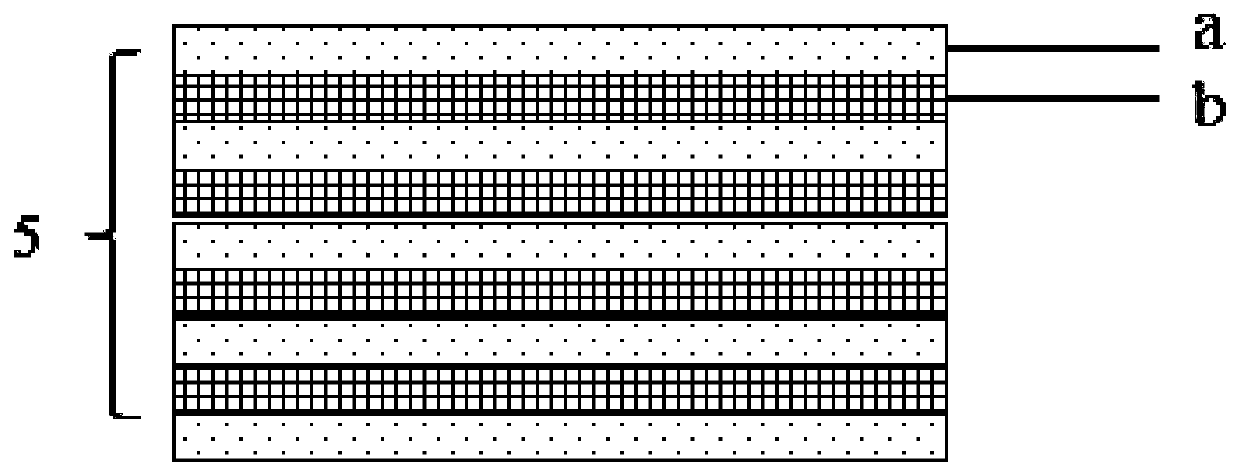

[0032] Wherein, the superlattice st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com