Test table capable of simulating lifting rotation operation platform in outer rail ultrahigh working condition of track

A technology for simulating track, lifting and rotating, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problem of not being able to truly simulate the outer track of the track, not being able to fully test the function of the lifting and rotating work platform, and not being able to test the lifting Problems such as the leveling of the rotating operation platform, to achieve the effect of ensuring the safety of the experiment and the reliability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

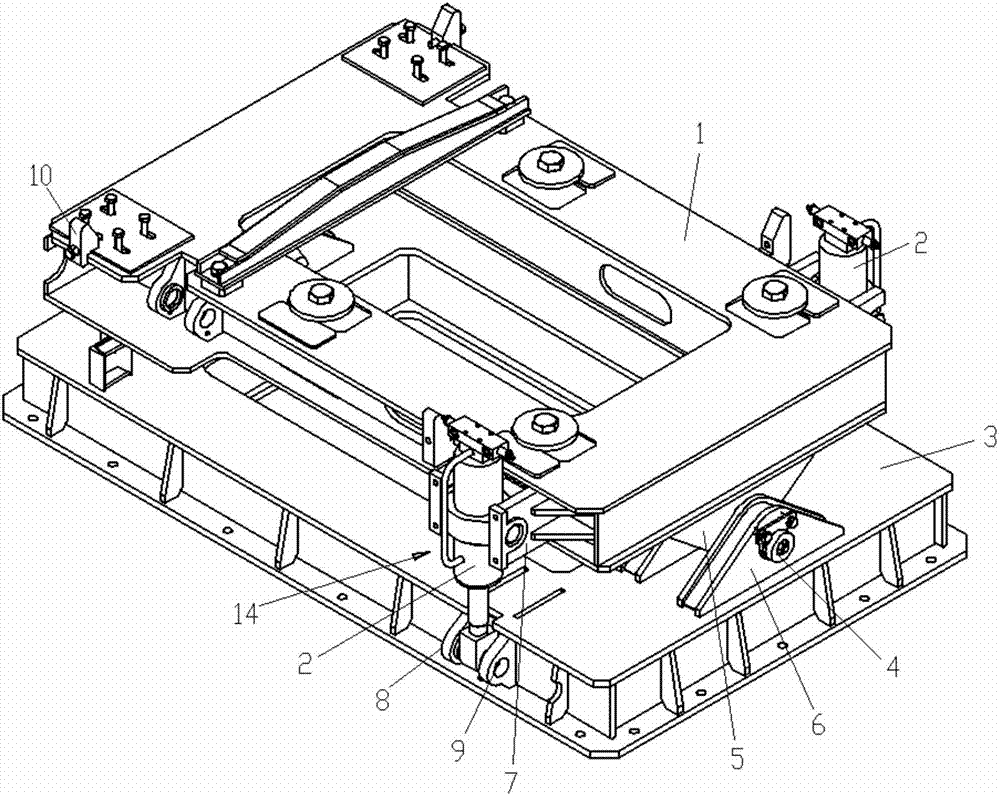

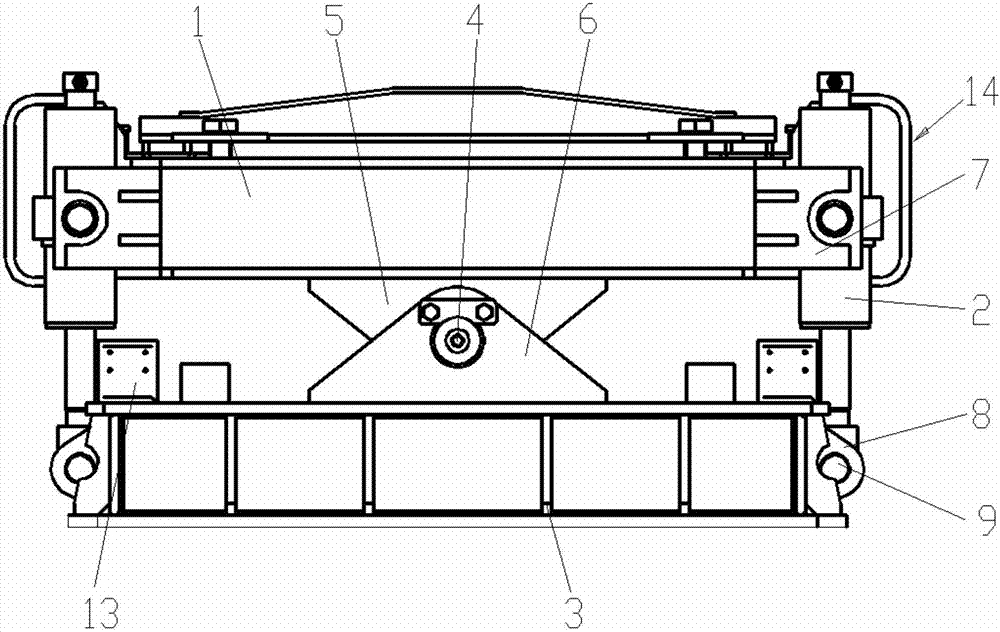

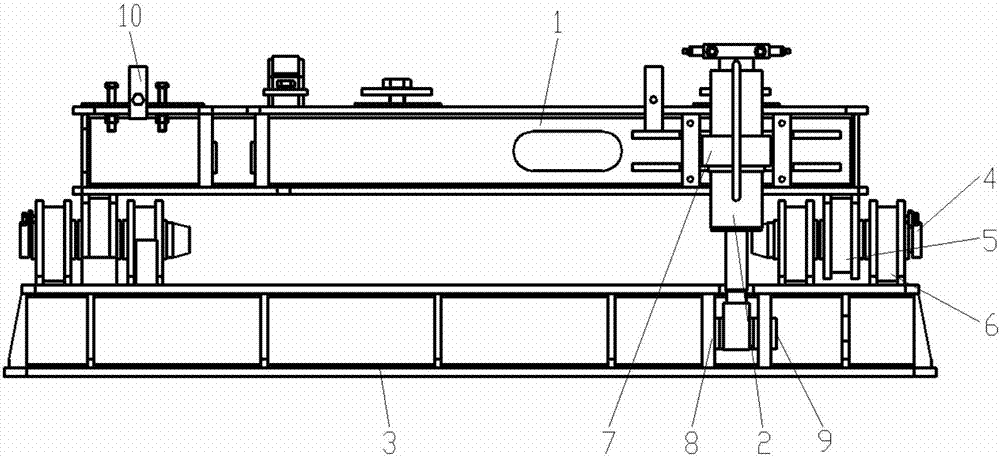

[0018] Attached below Figure 1-6 Embodiments of the present invention are described.

[0019] The test bench for the lifting and rotating operation platform that can simulate the ultra-high working conditions of the outer rail of the track, such as figure 1 and 2 As shown, it includes an upper frame 1 and an underframe 3, the underframe 3 is fixed on the ground by anchor bolts, the upper frame 1 is placed on the top of the underframe 3 and its lower front and rear ends are hinged with the upper front and rear ends of the underframe 3, specifically The front and rear ends of the upper frame 1 are provided with upper shaft seats 5, and the front and rear ends of the bottom frame 3 are provided with lower shaft seats 6 corresponding to the upper shaft seats 5 on the upper frame 1. The upper frame 1 and the bottom The upper shaft seat 5 and the lower shaft seat 6 at the corresponding ends on the frame 3 are hinged by pin shafts 4 . The four corners of the upper end surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com