Cut tobacco online weighing device and weighing method

A technology of weighing device and shredded tobacco, which is used in measuring devices, weighing equipment for materials with special properties/forms, weighing, etc. Small, simple and compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, describe in detail as follows:

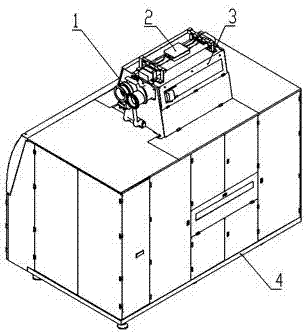

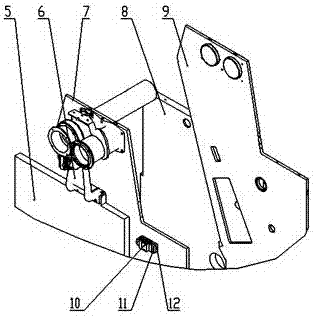

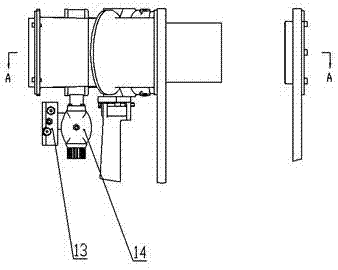

[0024] exist figure 1 and Figure 2A Among them, the wind wire feeding interface 1 is connected to the movable wallboard Ⅰ7 through screws, the cantilever beam weighing mechanism 2 is connected to the movable wallboard Ⅰ7 and movable wallboard Ⅱ8 through screws and cylindrical pins respectively, and the suspended hopper 3 is weighed with the cantilever beam through screws. The mechanism 2 is connected, the fixed wallboard I5 and the fixed wallboard II9 are respectively connected with the bottom plate 4 through screws, the movable wallboard I7 and the movable wallboard II8 are respectively connected with the bottom plate 4 through linear guide rails or rotating pins (not shown).

[0025] exist Figure 2B and Figure 2C Among them, in the wind wire feeding interface 1, the tobacco inlet flange 15 is connected with the double-hole channel 16 of the fixed inclined opening through screws, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com