Fixing device for preventing expansion of boiler connecting pipeline and guiding

A technology for connecting pipes and fixing devices, which is applied to the components of steam boilers, steam boilers, pipe supports, etc. It can solve the problems of difficult selection of spring hangers, easy failure and jamming, and large space occupation, so as to save space, Save cost and reduce the effect of welding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

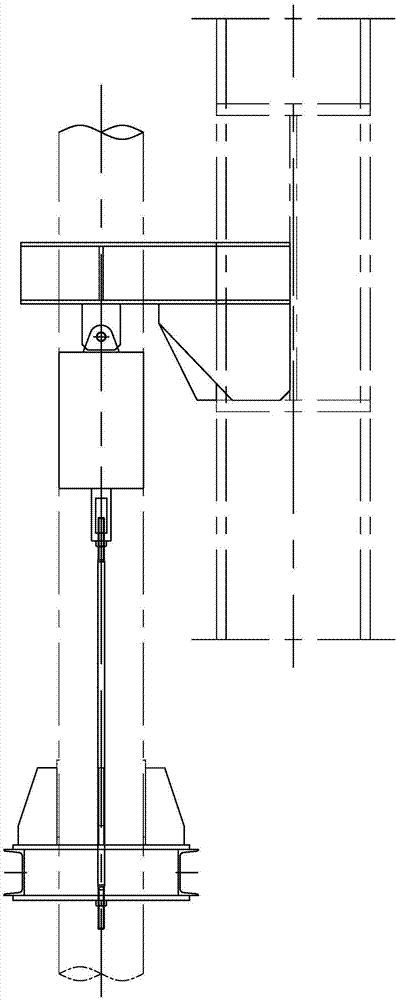

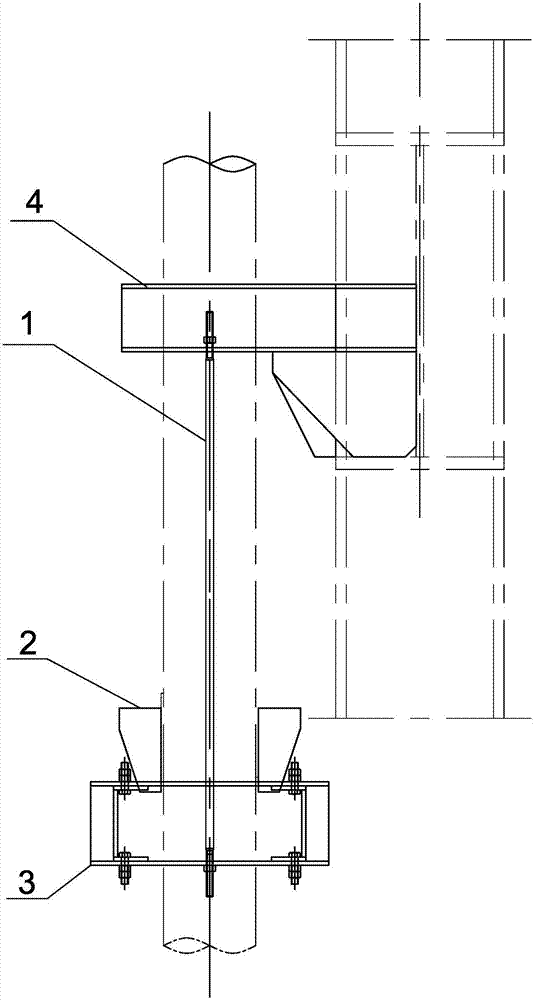

[0007] Specific implementation mode one: combine image 3 , Figure 4 , Figure 5 Explain that a fixing device for solving the expansion and guiding of boiler connecting pipes in this embodiment includes a boom 1, a support rib 2, a support beam 3 and a bracket 4, the upper end of the boom 1 is detachably connected to the bracket 4, and the lower end is connected to the support beam 3 detachable connection, the support rib plate 2 is fixed on the connection pipe and is located on the upper part of the support beam 3, the connection pipe passes through the center of the support beam 3, the support beam 3 has a gap 5, the support rib plate 2 is stuck on the gap 5 and It can drive the support beam 3 to move horizontally.

specific Embodiment approach 2

[0008] Embodiment 2: The supporting ribs 2 in this embodiment are four ribs with a slope, fixedly connected to the connecting pipe, and the surface where the supporting ribs 2 contact with the bottom of the notch 5 is an inclined plane. The inclined plane forms an acute angle with the support beam 3, and the inclined plane extends in the expansion direction of the connecting pipeline. With such an arrangement, the expansion of the pipeline can drive the support beam to move back and forth in the length direction of the waist-shaped hole through the support rib plate with a slope, so as to eliminate the influence of thermal expansion. Others are the same as the first embodiment.

specific Embodiment approach 3

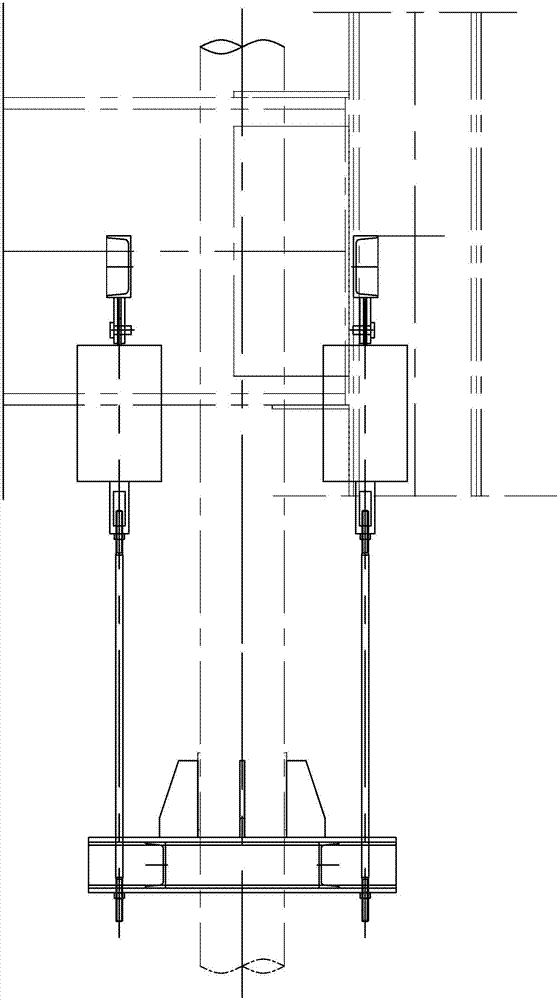

[0009] Specific implementation mode three: combination Figure 5 Note that the support beam 3 in this embodiment includes a side beam 3-1 and a sliding beam 3-2, two waist-shaped holes are opened on both sides of the side beam 3-1, and two round holes are opened on both sides of the sliding beam 3-2. The hole is connected with the side beam 3-1 and the sliding beam 3-2 by the bolt through the round hole and the waist-shaped hole, and the side beam 3-1 and the sliding beam 3-2 can relatively slide in the waist-shaped hole. In this way, the expansion of the pipeline can drive the sliding beam 3-2 to move along the length direction of the waist-shaped hole on the side beam 3-1. The supporting beam is detachable and assembled by bolts, which is convenient for positioning and assembly, and is easy to replace. Only the bolts and nuts need to be replaced to improve safety. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com