A method for plugging gas pipelines and a device for realizing the method

A technology of gas pipeline and plugging method, which is applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., which can solve the problems of weakened compression effect of sealing briquettes, loosening, secondary leakage, etc., to ensure leakage work Up to the standard, not easy to secondary leakage, convenient plugging work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

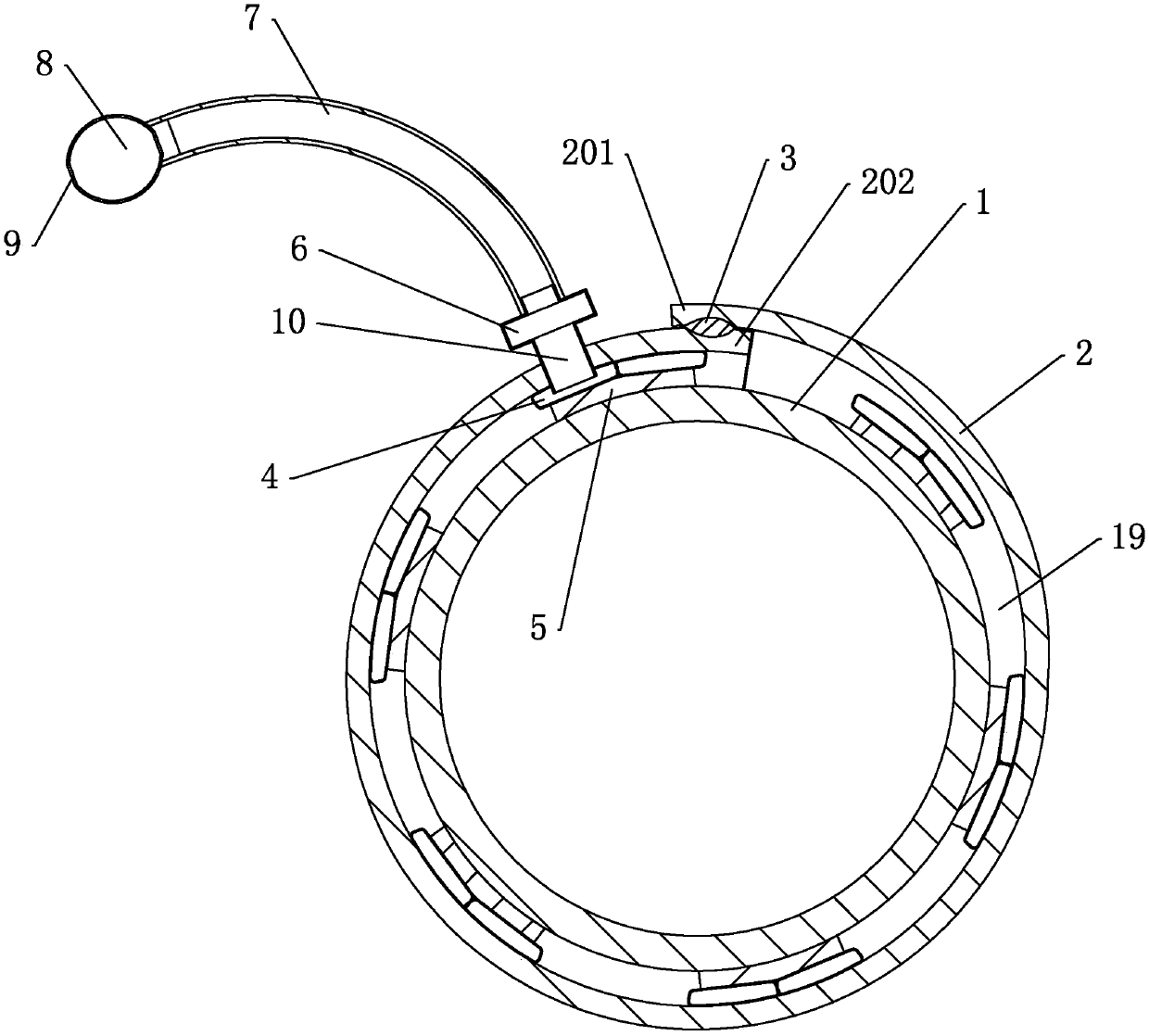

[0038] Embodiment 1: A kind of plugging method of gas pipeline, refer to figure 1 and figure 2 As shown, the method includes the following steps in sequence:

[0039] a. The emergency repair personnel of the gas company arrive at the site as soon as possible, prepare fire extinguishers, explosion-proof fans, etc., and use experience or equipment to find out the specific leakage point of gas pipeline 1 according to the site conditions, and clean up the anti-corrosion substances, rust and impurities on the pipelines around the leakage point. Clean, so that the surface of the gas pipeline 1 around the leakage point is flat;

[0040]b. According to the diameter of the gas pipeline 1, select a leakage plugging device that matches the diameter of the gas pipeline 1, wrap the soft body 2 on the leakage plugging device on the gas pipeline 1 in an annular shape, and put the The first end portion 201 and the second end portion 202 are fixed together, the soft body 2 and the gas pipel...

Embodiment 2

[0043] Embodiment 2: a plugging device, used to realize the above embodiment 1, such as figure 1 As shown in the figure, it includes a soft body 2 that is wrapped around the gas pipeline 1. The soft body 2 is made of soft material and can be curled and folded to form a ring. The two ends of the soft body 2 are the first ends respectively. part 201 and the second end part 202, after the soft body 2 is tightly wound on the gas pipeline 1, the first end part 201 and the second end part 202 are fixed by glue Glue 3, preferably acrylic adhesive, acrylic adhesive has adhesiveness and anti-corrosion, the first end 201 and the second end 202 are fixed and bonded by coating, which can avoid the first end 201 and the second end 202. The connection between one end portion 201 and the second end portion 202 is affected by the corrosion of corrosive substances, and the bonded soft body 2 is tightly attached to the outer circumferential surface of the gas pipeline 1 .

[0044] combine fi...

Embodiment 3

[0048] Embodiment 3: a leakage plugging device, which is different from Embodiment 2 in that, as image 3 and Figure 4 As shown, the first end portion 201 is provided with a through hole 14 and a nut 13 penetrating the inner and outer surfaces of the first end portion 201, the second end portion 202 is fixedly connected with a bolt 12, and the bolt 12 passes through the through hole 14 and is connected to the nut 13. The first end 201 and the second end 202 are fixed by screw thread; the first end 201 facing the inner surface of the gas pipeline 1 is fixedly connected with an inclined first ratchet 15, and the first ratchet 15 is upwards. It is gradually inclined to the right, the outer surface of the first end 201 is fixedly connected with the inclined second ratchet 16, the inclination direction of the second ratchet 16 is consistent with the inclination direction of the first ratchet 15, and the first ratchet 15 and the second ratchet teeth 16 engage and interfere with ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com