Curve orbit system with sliding blocks having independent driving force

A technology of curved guide rail and driving force, applied in the field of curved guide rail system, can solve the problems of increasing power consumption, increasing the weight of the motion system, easy to break the belt, etc., to achieve the effect of reducing the outer diameter, reducing production, and convenient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The mechanism and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings. In order to better illustrate this embodiment, some components in the drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art, some known structures and their descriptions in the drawings may be omitted. understandable. The same or similar reference numerals correspond to the same or similar components.

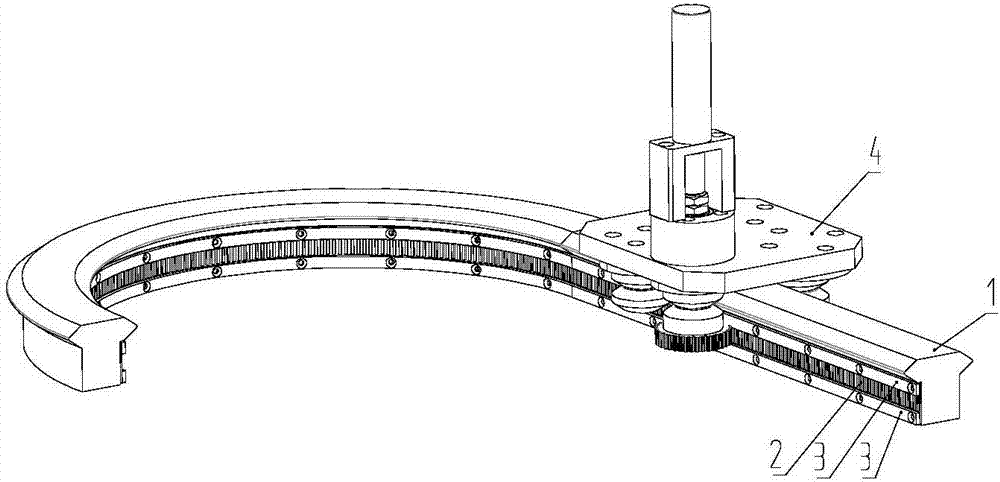

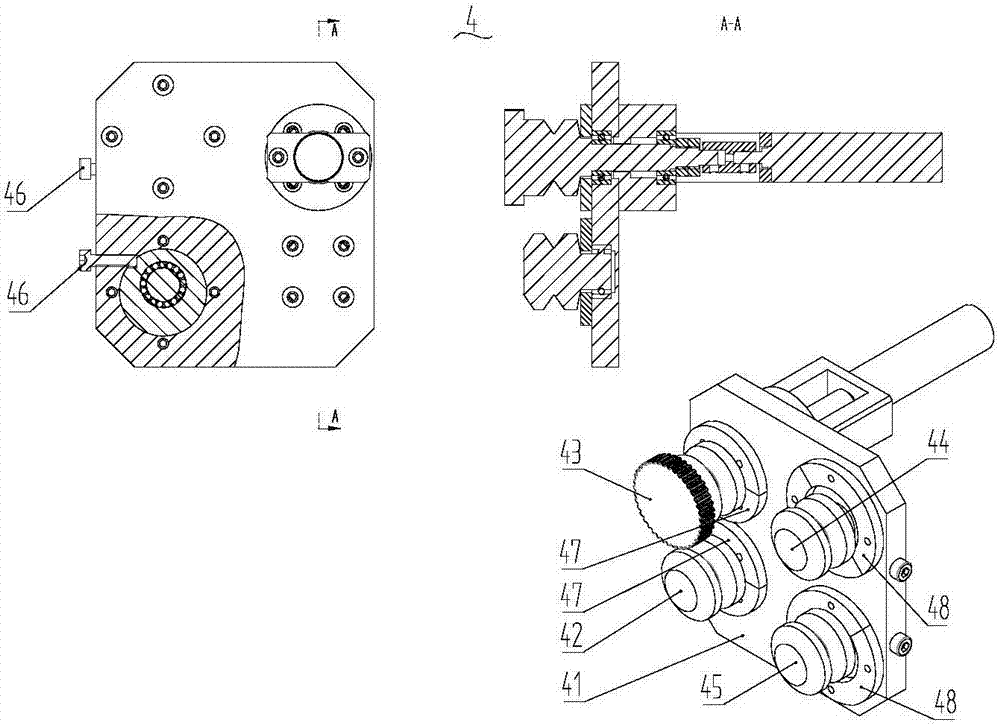

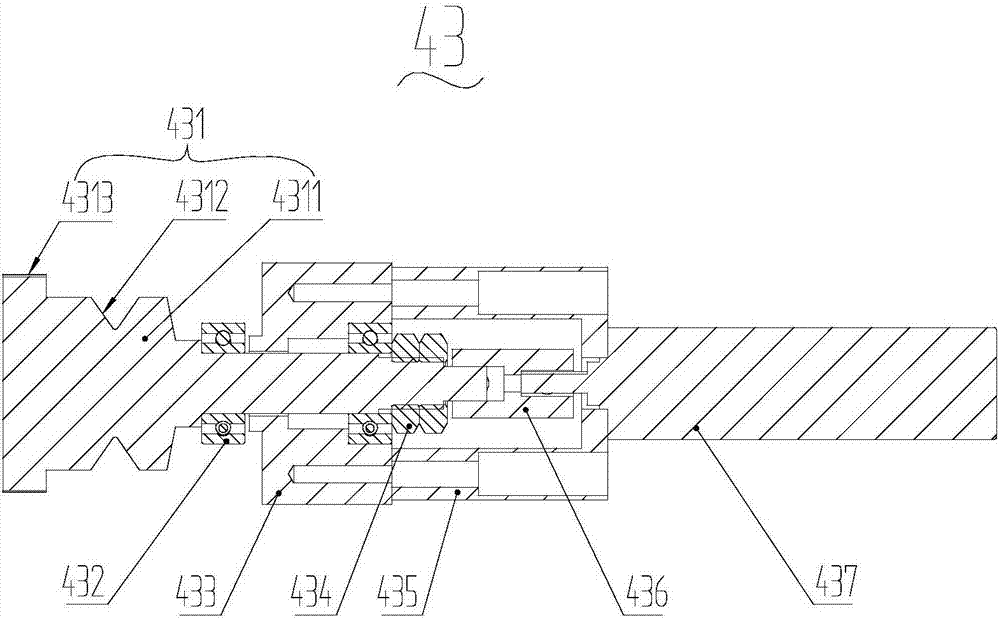

[0039] See Figure 1-6 As shown, the present invention provides a curved guide rail system with an independent driving force for the slider, which is characterized in that it includes a curved slide rail 1, a toothed belt 2 arranged on one side of the curved guide rail 1, and a belt at the upper end and the lower end of the toothed belt 2 The pressing strip 3 on the surface is arranged on the slider 4 above the curved slide rail 1; the slider 4 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com